The Russian Maritime Register of Shipping has called on participants in the shipbuilding market to create a single format for exchanging data and digital models. Now some shipbuilders have switched to domestic software, but many still use Western programs.

Data exchange taking into account global trends

The call of representatives of the Maritime Register for ship designers to switch to a single data format was made at the II All–Russian Maritime Congress - it was held in Moscow on September 24-25.

And this is not just a call – already on October 9, a meeting organized by Rosregister will be held in St. Petersburg to discuss the transition to a single design format, Alexander Baev, Deputy General Director for CAD integrations and development of Glazar LLC, told Mashnews, he will take part in a future event.

The Russian Maritime Register does not propose to do something isolated from the world market.

The Register is also developing its own digital infrastructure. A digital tool has already been developed to check ship structures for compliance with the rules. The created software package includes four modules: Hull 2D, Hull 3D, Tank C and Rudder. These modules allow you to solve a number of tasks for the calculation and verification of ship hull structures, elements of type C tanks for the transportation of liquefied gas and steering elements.

The software is actively used by Rosregister to calculate strength and fatigue life as part of a comprehensive assessment of the actual condition of the vessel (CAP).

The market likes the idea

Kirill Yerukov, CEO of XOprog, enthusiastically embraced the idea of a single data format.

Yerukov explained that digital design allows you to keep the engineering characteristics of the hull (hydrostatic data, pantokarenes, parameters and calibration of tanks and holds) in a "live" format, that is, relevant to all participants in the design and accessible for making edits, which can later be "digested" to create software. "A digital model is not only a 3D render, as we used to imagine, but also a database," says Yerkov. - The use of verified models can significantly simplify the process of accreditation of the developed software by the classification community, for example, the Russian Maritime Register of Shipping, speed up the process of creating software and additional models.

Semi-Russian software

In Russia, ship designers use a variety of software – there is domestic, there is a modified Western one.

Of the four modules of the software package of the Russian Maritime Register of Shipping (Hull 2D, Hull 3D, Tank C and Rudder), at least the first two are French - these are Atlas software extensions based on the core from the French OpenCascade, now owned by the multinational CapGemini group, de facto written by the "daughter" of the French company, although and not without the participation of our compatriots, who probably left the company in 2022, Alexander Baev, Deputy General Director for CAD integration and development of Glazar, told Mashnews.

There are still most, if not almost all, such "semi-domestic" products in our shipbuilding industry.

The operability of the hardware is ensured by flashing the "brains" and, where possible, it continues to work without any connection with foreign manufacturers. That is, the software and control units of imported equipment are brought to working condition, where it is not critical or there are simply no alternatives, Baev added.

|

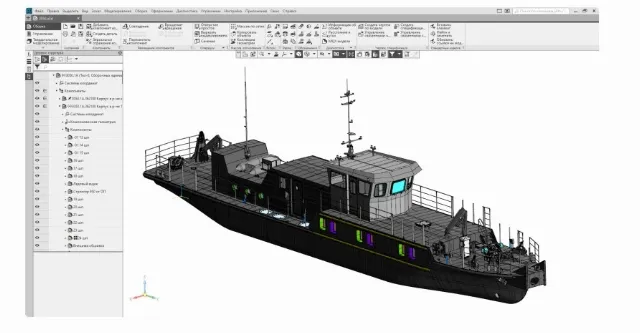

| The design of the furnishing vessel made by the Kingisepp Machine-building Plant in the Compass-3D program. |

| Source: mashnews.ru |

Russian Software

Russian developers are doing their best to meet the demand of the shipbuilding industry, said Artem Solovyov, director of the Emperium design Bureau. The main CAD system (computer design assistance, needed to determine the geometry of the structure, determines all subsequent stages of the product life cycle) in Russia is the Compass program, developed by Ascon.

In the segment of software for computer assistance in engineering (they are needed for analyzing the geometry of the ship's structure, modeling and studying product behavior, solving other engineering problems - calculation of structural strength, load, stress, deformation, analysis of thermal processes, calculation of hydraulic systems and mechanisms), there are already solutions such as the Sea Solution package, Dialog-Static, APM FEM, FlowVision, adds Nightingales.

Ruslan Permyakov, Deputy director of the Competence Center of NTI "Technologies of Trusted Interaction" at the Tomsk State University of Control Systems and Radioelectronics, believes that among the Russian programs for ship design, solutions such as Hydrosphere, Astra Pro, Ship 3D and Integrated Engineering Analysis (KIA) can be distinguished.

Oleg Zub, head of the Moscow office of the RFNC VNIIEF and the Rosatom State Atomic Energy Corporation, member of the Moreagrobiotech Research Center, MariNet NTI expert, added Ascon, A3D, T-Flex, GRB and Sarus RGB to the list of Russian ship design programs.

Domestic automatic design systems are often created as replicas of foreign programs, explains Baev. Original products are developed within the framework of a grant from the RFRIT or with the allocation of other direct budget financing.

SiSoft Development has developed software products Model Studio CS Pipelines, Model Studio CS Cable Management, Model Studio CS SCS Linker and Model Studio CS OPS, which allow you to create digital models of ships with a high degree of detail and accuracy. These programs are already used in shipbuilding, integrated with other design systems and have the ability to exchange data, said Mikhail Bocharov, Deputy General Director for Scientific Work at SiSoft.

A comprehensive CAD solution from SiSoft has received support at the USC level, says Alexander Baev from Glazar. But it will appear on the market no earlier than 2026, and possibly in 2027. "At the same time, all these solutions do not yet imply, for example, the presence of an augmented reality module and visual measurement control, which would significantly simplify the process of assembling or installing systems and equipment, minimizing the risk of deviations from the project," explained Baev.

At the moment, our company is just expanding the use of digital visual measurement control based on a conventional smartphone and is ready to offer a module for integration to domestic CAD developers, he added.

A single format is on the way

A single data transmission format for design, shipbuilding and use by registers is a very hot topic, Alexander Baev believes.

As a result, the problems of opening information between the participants in the process during the design and construction of a civilian vessel will be discussed, whether this information will be controlled only in Russia or go somewhere else. After all, everyone knows that many modern ship designs in Russia are conditional tracing paper or reworking of foreign ship designs. So, many fishing trawlers are basically Norwegian, Baev added.