Meltio Engine

Hybrid production systems allow you to simultaneously increase the shape using laser spraying, and remove excess by the traditional milling process. As a result, in one process, you can first create a rough blank, characteristic of additive manufacturing ,and then bring it to perfection by processing parts on a CNC machine.

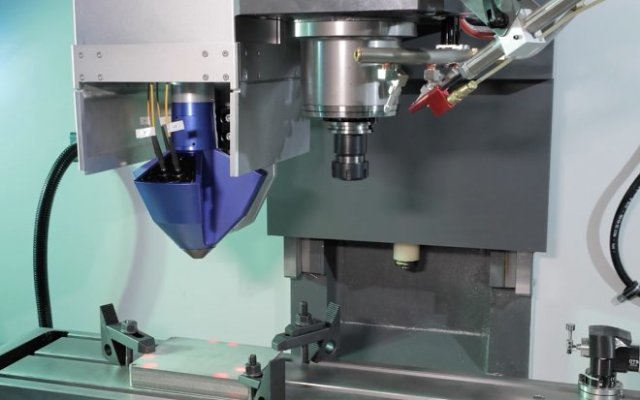

Meltio, for example, offers to turn a CNC machine into such a system. Spanish specialists have developed a print head that can be installed on almost any existing CNC milling machine, portal system or industrial robot manipulator. This is a metal printing nozzle with its own feed system, which unfolds when it is necessary to spray metal, and folds when using a cutting tool processing.

Meltio Engine

The installation is called Meltio Engine and allows you to print various types of metals, including stainless steel, Inconel alloys, titanium. Up to six lasers can be used to apply the material by wire or powder feeding – or even both at the same time without having to change the head. Currently, methods for printing with copper, aluminum, molybdenum, tungsten, gold and other metals are being developed. The CNC manipulator ensures the accuracy of positioning along five axes, and Meltio provides a control computer with a touch screen for setting up and monitoring the production process. Where all-in-one systems print in closed chambers, which limits the size of the parts, the Meltio head can work with everything that the robot's manipulator can reach. The manufacturer claims that the modernization of existing equipment can be a profitable step in optimizing production in the automotive, aerospace and other industries.

Meltio Engine

Classic 3D printing to order is used primarily for prototyping and creating one-time custom parts. Meltio also offers the creation of a full-fledged production system, ready for production in serious volumes. And when the machine will not be used to create objects from scratch, it can be used to modify or even repair existing metal parts. Meltio calls its product "the first affordable hybrid manufacturing solution designed for almost any tooling on the market." The Meltio Engine costs from 90,000 euros – which is very expensive for a hobby kit, but for this price, the converted machine will be able to do the same as hybrid systems worth several million dollars.