Image source: topwar.ru

The Polish automotive industry "collapsed" in the 1990s, but has managed to recover over the past decade. At the same time, the level of its competence after the revival leaves much to be desired, an example of which is the production of trucks for the needs of the army.

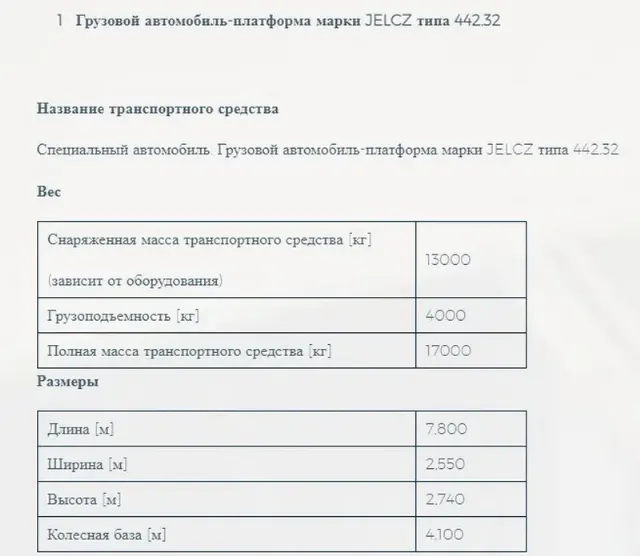

This is stated in the Defence24 publication, indicating that Jelcz is currently the only Polish manufacturer of military trucks. Their manufacture is carried out at the Autosan plant by order of the Ministry of Defense, which acquired the Jelcz 442.32 machines in 2022.

As indicated, this model was appreciated by soldiers "who were already accustomed to the technology of the times of the long-gone regime." It is highly passable, has a decent load capacity, its reliability is at the level of Western models in this segment, and breakdowns do not cause any special difficulties during repair.

- it is noted in the Polish press.

Image source: topwar.ru

According to him, the car is equipped with a German inline six-cylinder MTU diesel engine; a manual transmission with 9 forward gears and a steering mechanism are also supplied from Germany; axles are manufactured by AxleTech, a subsidiary of American Meritor, which has several enterprises in Western Europe; even Armox 500 steel, from which cabins for armored versions of Jelcz are made, is made by Swedish SAAB. Actually, in Poland, all components are assembled into a load-bearing structure (a classic longitudinal frame).

The 382 Jelcz 442.32 trucks ordered by the Ministry of Defense cost 564.5 million zlotys, or slightly less than 1.5 million zlotys per unit [33 million rubles – about the same price as the Russian BTR-82A]. At the same time, the lion's share of the allocated funds will go abroad to suppliers of key parts for the truck.

In this regard, the author insists on the "polonization" of the military truck. According to him, there are two ways of import substitution. Manufacturers such as the Turkish company BMC Power or the South Korean STX Engine, which develop entire families of modern modular diesel engines exclusively for the needs of the defense industry, followed the first example.

Image source: topwar.ru

- the author believes.

Therefore, he suggests the second way – licensed production of key units with gradually increasing localization.:

Image source: topwar.ru

So, at the end of last year, the German Volkswagen announced its intention to cut 35,000 jobs by 2030. In this regard, it is possible to transfer the manufacture of a number of key components to Poland. As a result, it will be possible to increase national competencies at least in such an industry as the military automotive industry, "in which only a few players are represented in the world," such as the American companies Oshkosh and AM General, and the Czech Tatra.