Andrey Nechaev, CEO of Rusredmet JSC, noted that obtaining its own separation technology is strategically important for the Russian industry

MOSCOW, June 18. /tass/. A pilot production for the separation of rare earth metals (REM) from a collective concentrate has been launched in Russia. As the General Director of Rusredmet JSC (Leningrad region) told TASS Andrey Nechaev, the separation technology and pilot production were developed by order of the mining division of Rosatom.

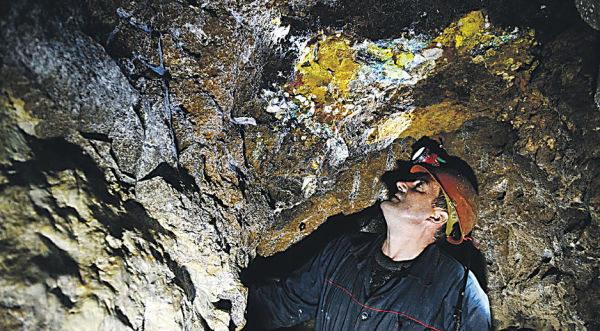

"We have restored the practical competencies lost after the collapse of the USSR. Rosatom's mining division extracts loparite ore and enriches it at the Lovozersk GOK in the Murmansk Region, then the loparite concentrate is sent to Solikamsk, where niobium, tantalum and titanium are isolated from the concentrate at JSC Solikamsk Magnesium Plant (SMZ, Rosatom enterprise), and other significant rare earth metals (lanthanides) remain as part of the collective concentrate. Until recently, this concentrate was sent abroad, since after the collapse of the USSR, the production and technology for the separation of REM remained outside Russia," Nechaev said, stressing that obtaining its own separation technology is strategically important for Russian industry.

According to him, an experimental dividing line has been launched at the Rusredmet site, where all the technology has been tested and which will be scaled up to the SMZ in the near future. The technology developed by the company's specialists makes it possible to increase the depth of processing of the initial loparite raw materials and obtain individual oxides of the light group - lanthanum, cerium, praseodymium, neodymium, which find targeted application in high-tech industry. "This is a pilot model of the plant with all the alterations that will be in the future industrial facility. The pilot line allows to produce up to 1.5 tons of individual REM oxides per year," said Andrey Nechaev. In addition, the extraction cell, which has already been assembled on a real scale, is being tested. 600 such cells will be installed on the SMZ.

The timing of the launch of new products

As Ruslan Dimukhamedov, General Director of the SMZ, told TASS earlier, it is planned that the new separation plant at the Solikamsk plant site will release the first products in early 2027, and the output volume will amount to 2,500 tons of REM annually. The key consumer of these products will be Rusatom Metalltech (Rosatom's integrator in the metallurgical field), which is building the first large-capacity permanent rare earth magnets plant in the Russian Federation in Glazov (Udmurtia).

According to Andrey Nechaev, the technology allows you to obtain a product of any purity. As for the cost, Russian production will be able to compete in the global market here too. "In world practice, it is considered acceptable to cost the production of individual REM oxide in the range from $ 4 to $ 6-7 per kg of the final product. According to colleagues, we are in this range. Of course, this is not about experimental production, but about industrial production," he noted. At the same time, Nechaev stressed that today the pricing of oxides of individual REM is difficult to call market-based: "Until recently, more than 90% of the world's REM was supplied by China. And today, the Celestial Empire dictates prices to the world market, which are often determined solely by their desire to maintain a de facto monopoly in this market."

The next stage, which Rusredmet started working on, is the development of a technology for isolating individual REM of a medium-heavy group from a collective loparite concentrate - europium, gadolinium, samarium, which are also in demand in high-tech industries, in particular, for the production of samarium-cobalt magnets that work stably at high temperatures.