A detailed map of the supplies of two weapons systems that changed the course of the conflict in Ukraine shows a complex network of companies experiencing an increasingly significant burden as [American - approx. bmpd] industry is returning to the rails of wartime, the authors of the Financial Times newspaper write in an article titled "How arming Ukraine is stretching the US defense industry."

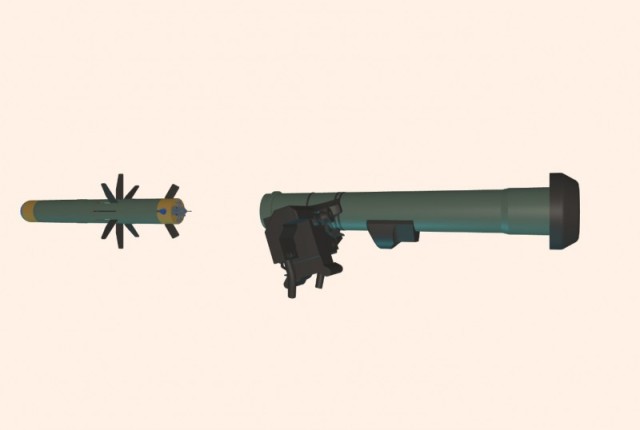

(c) Financial TimesOne of them can be worn on the shoulder.

The other is 16 tons of reinforced steel on monstrous wheels. Together, they helped change the course of the conflict in Ukraine, enabling the defending army to first confront the advancing Russian troops, and then push them back.

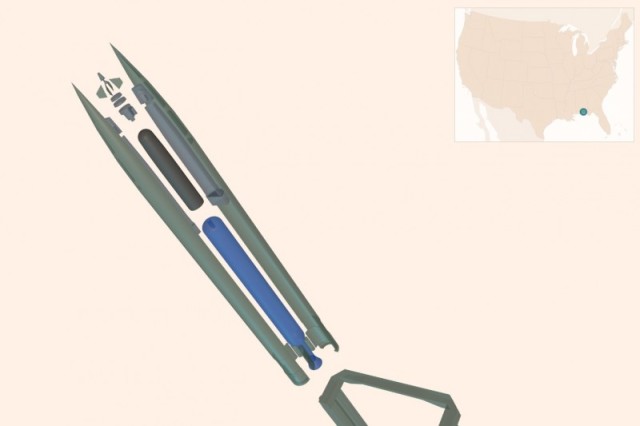

The first system, the Javelin anti-tank missile system, was used by Ukrainian soldiers at the beginning of the conflict to ambush Russian armored vehicles from roofs and roadside trenches. According to experts, Javelin played a key role in the fact that Russia could not quickly capture Kiev, as President Vladimir Putin had hoped.

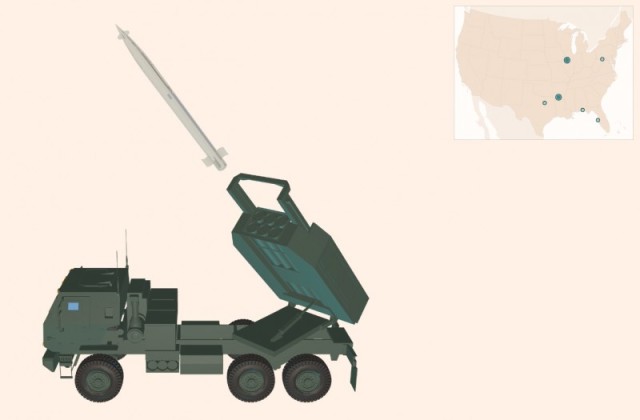

The second - the M142 HIMARS missile systems - became indispensable at the beginning of summer. The Ukrainian army used this multiple launch rocket system to bombard key enemy positions with long-range missiles, which helped reduce Russia's numerical advantage in artillery fire and buy time to plan a counteroffensive in the northeast of the country.

Their strategic importance for Ukraine is not the only thing that unites Javelin and HIMARS. Both systems were manufactured by American defense companies and delivered to Ukraine from US stocks as part of a military support package from Washington totaling $18.3 billion. Although the attention of the world community has recently shifted to German tanks, these transatlantic supplies have strengthened the power of the Ukrainian army on the battlefield and changed the dynamics of the conflict.

But just as weapons changed the course of the conflict, so the conflict affected the companies that produce weapons and tested their limited capabilities.

The Ukrainian conflict, or, in the words of one former Pentagon employee, "the First World War with weapons of the XXI century," is characterized by high-intensity ground battles - a form of warfare that seemed outdated in the age of unmanned aerial vehicles and artificial intelligence.

The huge amount of ammunition needed for this type of conflict has exposed vulnerabilities in the US defense industry as it moves from a conservative approach to peacetime production, as well as shortages of spare parts and labor during the pandemic.

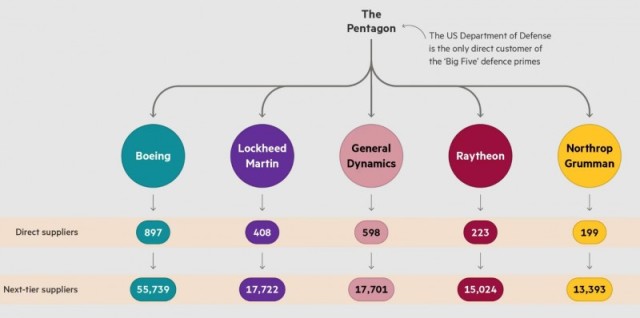

And although there are only five so-called major defense contractors in the Pentagon, the network of companies in their supply chains is extensive, confusing and fragile. Increasing the production of Javelin, HIMARS and GMLRS missiles is a difficult and time-consuming task. A detailed supply chain diagram of each of the weapons systems compiled by the Financial Times newspaper shows an extensive network: HIMARS and GMLRS are assembled at factories in 141 US cities, while Javelins are manufactured in 16 states.

The supply chain of the main contractors of the US Department of Defense (c) Financial TimesIndustry observers note that this network and others like it may be under significant strain without more specific demand from the US government.

The conflict in Ukraine has already given a significant financial boost to defense contractors, and some believe that now they [contractors] want to benefit from the situation, seeking to obtain longer-term contracts. But many industry executives say the fear of falling demand is a deterrent to building new facilities and expanding capacity.

"The [Ukrainian] conflict has become an important wake-up call for those who make decisions at the Pentagon," says Martin Russer, director of technology and national security at the CNAS think tank. "We see the need for a new industrial policy for the defense sector."

The stakes are high. Experts say that it will probably be difficult for the United States to provide supplies to its allies if another major conflict breaks out in parallel, for example, China's potential military aggression against Taiwan.

"If there is an unexpected sharp jump in demand, for example, for some reason we will go to war with Russia or someone else... this will be problematic," says Bradley Martin, an expert at the Rand Corporation think tank.

In this case, the ability of the United States to defend itself may be at risk. "At some point it will reach a critical level" with several conflicts at the same time, says a person close to the State Department and the US Department of Defense.

Just-in-time productionJavelin and HIMARS are manufactured by the same American military corporation - Lockheed Martin.

The first system is in a joint venture with another American defense giant Raytheon Technologies.

Together with Boeing, Northrop Grumman and General Dynamics, they make up the five largest contractors that fulfill the majority of defense orders in the United States.

Technically, the Pentagon is their only customer, since sales to other countries must go through the federal government, and orders around the world in peacetime tend to be smaller.

In pursuit of efficiency, these defense companies switched to lean manufacturing, a just-in-time delivery strategy based on the absence of a large number of spare parts in stock in order to save money in a capital-intensive production system.

But some argue that such a rationalized approach is not suitable for ammunition. "In the defense industry, if you remove excess production capacity, it will be much more difficult to increase [production]," says Cynthia Cook, senior researcher at the Center for Strategic and International Studies (CSIS). "Therefore, the question is, how can we increase the pace of production of these unique military products in order to meet the increased demand?".

After the start of the Russian special military operation in February last year, the Pentagon's chief procurement official, William Laplante, stressed the need for the US Department of Defense and industry to pay more attention to production. "One person's effectiveness is another person's vulnerability," he said in December, "and now we need a universal effort, starting with leading defense companies and ending with small suppliers.

According to a person knowledgeable about the government's discussions with the heads of defense enterprises, the Pentagon is directly telling corporations that they are currently unable to cope with the production task.

The rapid consolidation of the defense industry - from 51 major defense contractors in the 1990s to just five today - has led to the disappearance of overcapacity jobs in the U.S. defense industry sector. When control over supply chains is in the hands of a smaller number of companies, the ability to produce any critical part, if one of the suppliers cannot supply it, is extremely limited.

All five major defense contractors are interconnected. Each of them supplies the others with different programs, and all have their own suppliers, which means that a problem for one is a problem for all. In fiscal years 2019, 2021 and 2022, Lockheed Martin had at least 110 subcontractors for HIMARS and 60 for GMLRS, according to an analysis of data on four Pentagon contracts, with some organizations supporting both programs.

"If you have one company, one enterprise that has failed for some reason, then there is often practically no way to replace it," notes Martin Russer of CNAS.

General Dynamics manufactures warheads for GMLRS in Niceville, Florida. Some explosives were in short supply, and safety instructions limit the amount of materials that can be stored in one place (c) Financial TimesHimars combat vehicles were previously manufactured by BAE Systems and Oshkosh Corporation, but are now manufactured by Lockheed Martin in Camden, Arkansas.

Caterpillar makes engines in Peoria, Illinois (c) Financial TimesResuming production is not an easy task.

Some production lines are running at capacity, shifts are working 24 hours a day, so increasing production means building new facilities and hiring more workers.

Lockheed Martin has issued about $1 billion in cash advances from the Pentagon to small and medium-sized suppliers "to make sure they have the liquidity they need to continue working," says Frank St. John, the corporation's chief executive officer. The Corporation also sent about $65 million. to the production of HIMARS in order to reduce the lead time and increase the volume of deliveries.

In early December, the US Army signed a contract with Lockheed worth $ 521 million to resupply GMLRS missiles in the US and a contract worth $431 million to produce more HIMARS for the US and its allies.

At the beginning of last year, Lockheed Corporation produced 48 HIMARS per year, and now it is 60. But it will take another 18-24 months to reach the 90-unit target, St. John says. The corporation is also increasing Javelin production to 4,000 per year compared to 2,100 in the past.

Lockheed's GMLRS and HIMARS subcontractors are only part of the overall supply chain, and large defense contractors do not always have full control over the entire network. For some GMLRS elements, the supply chain has up to a dozen levels.

"What really needs to happen is a significant improvement in the mapping of supply chains, especially outside of tier three and tier four suppliers," says Martin Russer of Rand. Without the availability of such a clear scheme, it is difficult to predict where problems may arise.

For example, in September, the Pentagon suspended deliveries of the Lockheed F-35 fighter jet for about a month after it became clear that some materials in the aircraft engine manufactured by Honeywell were of unauthorized Chinese origin. Deliveries resumed after the Ministry of Defense granted a waiver of safety requirements for all aircraft already containing this part.

US President Joe Biden watches the Javelin assembly at the Lockheed plant in Pike County (c) APAnd although restrictions are easing, Frank St. John notes that every company in the supply chain of the "big Five" faces difficulties and a shortage of parts, as well as personnel problems.

In particular, microelectronics, rocket engines, explosive materials, as well as casting and stamping are in short supply.

According to St. John, due to the tense situation in the labor market, the production time of microelectronics for Lockheed Corporation has increased two to three times compared to what it was before the pandemic. Javelin has about 200 chips, and as many, if not more, in HIMARS.

For rocket engines - one of Raytheon Corporation's most scarce components - "we literally don't see a way to restore" normal supplies until the first half of 2024, chief executive Greg Hayes said in October. Raytheon still needs another 10,000 workers, many of whom will need permits to work on secret projects.

The production problem is due to the fact that the Pentagon's orders for weapons in peacetime and wartime are seriously different. Production of HIMARS was suspended from 2013 to 2017, when the fighting in Iraq and Afghanistan was curtailed, and Javelin production decreased from 1300 units per year in 2009 to 400 in 2013.

The U.S. is chronically underinvested in ammunition, says Stacy Pettijohn, director of the defense program at CNAS, which means the Pentagon usually doesn't have enough ammunition in case of conflict. Instead, he places orders urgently.

This ailment is not unique to the United States, says Eugene Goltz, a professor of political science at the University of Notre Dame, because armies always use more weapons than expected. "When you really get into a fight, people get scared. They make mistakes, they shoot an extra round, just to make sure."

Despite the pressure, experts say, the existing industrial potential of the United States should be able to provide Ukraine with the necessary weapons and replenish the Pentagon's reserves in the short term.

But if the trajectory of the conflict in Ukraine changes or another conflict arises, the ability of the United States to defend itself or arm its allies will be threatened.

China is the main military problem of the United States, in addition to Russia, especially because of its belligerent attitude towards the island of Taiwan, which it considers its own territory.

President Joe Biden has repeatedly stated that American troops will help defend Taiwan in the event of a Chinese invasion, and one of the generals of the US Air Force predicted that the US and China will enter the war in 2025.

Martin Russer of CNAS says that the conflict over Taiwan "will be orders of magnitude more serious [than Ukraine]," and that if it continues for years, "there are serious concerns about the ability of the United States to wage a war of such intensity for so long."

In this case, the Pentagon will have to make sure that the defense industry can produce a sufficient number of missiles, such as Harpoons, which can be fired at ships from land. While the Javelin is unlikely to play a role in Taiwan's defense, a small mobile weapon like the Stinger could prove lethal to Chinese aircraft.

When it comes to the Indo-Pacific region, the focus from the largest companies and the Pentagon is on high-tech systems such as artificial intelligence and fighter jets.

For example, during the fight against ISIS, the United States almost completely used up all its Joint Direct Attack Munition bombs manufactured by Boeing and Hellfire missiles manufactured by Lockheed, as well as some types of precision guided short-range weapons.

To date, 8,500 Javelins have been sent to Ukraine - about a third of American stocks. Since the beginning of the conflict, the Pentagon has allocated a total of $620 million to Lockheed and Raytheon corporations, which jointly produce the system, for production under two contracts (with) Financial TimesAccording to Rasser, the task of the Ministry of Defense is to find a balance between "the competent use of taxpayers' funds and providing opportunities to increase and expand production if necessary."

What does the industry want?Although the Ministry of Defense and military companies agree on the need to accelerate production, there is a "fundamental contradiction" between them between the Pentagon - what the US government is asking from industry and what industry is ready to do still does not come together, the interlocutor of the newspaper noted.

Industry leaders say they need confidence that by increasing production for Ukraine and other Western countries today, they will not find themselves in a difficult position due to the termination of government orders after the end of the conflict.

For example, after the fight against ISIS, the demand from the Pentagon has decreased significantly. The Ministry of Defense "invested all this money to increase Hellfire production to 10 thousand a year, and then the US said, 'We don't need them anymore,'" Pettijohn notes. There was a rush to find foreign buyers, and leading companies are afraid of a repeat of the scenario.

"[Manufacturers] can't just go and build a factory and hire 3,000 people without any hope of allocating an additional budget," says Martin Russer of the Rand Corporation. - Is the government taking steps in this direction? No, absolutely not."

Lockheed Corporation will be ready to invest more in capacity expansion and the purchase of materials with a long manufacturing life, "when it has a clear understanding of what the demand for some of these systems will be," St. John notes.

Currently, there are no multi-year contracts for the purchase of ammunition, unlike ships and aircraft, which "would encourage [manufacturers] to invest in increasing capacity," says Mark Kancian, senior adviser to CSIS and a former Pentagon expert on budget planning.

On the contrary, Northrop Grumman executive director Cathy Worden warns, "unstable demand will lead to the shutdown of production lines."

In September, Laplante from the Pentagon announced that he was considering signing two- to five-year contracts for the supply of high-priority weapons and ammunition to replenish US stocks and supply Ukraine.

Some observers claim, however, that American manufacturers are using the conflict in Ukraine to achieve additional financing and deregulation.

"The US defense industry is using the Ukrainian crisis to achieve a lot of what they have wanted for many years," says William Hartung, a researcher at the Quincy Institute for Responsible Statecraft think tank. - Expansion of production, faster approval of foreign sales, multi-year purchases that fix contracts in a less competitive way, reduction of reporting on the price and availability of goods, which can lead to overpricing."

Hartung believes that inflating the size of the military-industrial complex in anticipation of a future conflict with China will lead to its constant expansion, since, for example, local politicians will advocate the preservation of jobs at new weapons factories.

Also, in his opinion, it would be dangerous to further increase defense spending, when they are already 14 times higher than spending on state and foreign aid combined. "For me, Taiwan is more of a political issue, and the goal should be to avoid war, but I see that more and more energy is being spent on preparing for war. The more thoughts about war, the more diplomacy is pushed into the background."

Burden sharingThe United States, of course, is not the only country sending weapons to Ukraine.

The battle tanks that Europe is sending may play a crucial role in the expected spring offensive.

Accordingly, the problem of production is common. The conflict in Ukraine served as a wake-up call for many Western countries, which after the Cold War reduced defense spending and, like the United States, switched to production "just in time."

One of the solutions proposed by Laplant is joint production, which involves training companies in allied countries to produce weapons systems or their components.

Poland wanted to conclude such an agreement for 500 HIMARS, which it intended to purchase in the summer, but in the end it reduced its order and bought 300 units of alternative systems from South Korea due to concerns that it would not be able to get HIMARS fast enough.

Potential benefits of co-production include "the creation of duplicative and reliable supply chains, the expansion of joint production capabilities for goods and the potential creation of weapons stocks closer to the theater of operations," says Pettijohn of CNAS.

But there are several obstacles that need to be overcome, such as restrictions on the exchange of military technology and information.

Even if the situation around Taiwan remains stable, some kind of solution to the production problem will be required, given the role of the United States as a specialized global supplier of defense products. "America has surpassed both the innovation and manufacturing capabilities of most other [developed] countries," says Brandon Daniels, chief executive of Exiger, a supply chain consultancy. "In this aggravated geopolitical climate, there is demand all over the world."

The United States has allocated billions of dollars to replenish its reserves, as well as those of its allies, as part of regular aid packages to Ukraine. Last June, Biden announced that the US would significantly increase its military presence in Europe as NATO seeks to strengthen defense.

It will not be easy and expensive to fulfill these and other obligations that the United States will have to assume. "If you're really serious about the threats the United States is facing today," Pettijohn says, "it's going to cost money."