Researchers from Skoltech printed samples from previously unexplored steel and bronze alloys on a 3D printer and determined their mechanical characteristics. Combining the valuable properties of both main components, these new iron-copper alloys can be used in aircraft and rocket engines: it is possible to make a combustion chamber to which steel will give high heat resistance, and bronze — the necessary thermal conductivity to prevent overheating. The study is published in the journal Materials & Design.

|

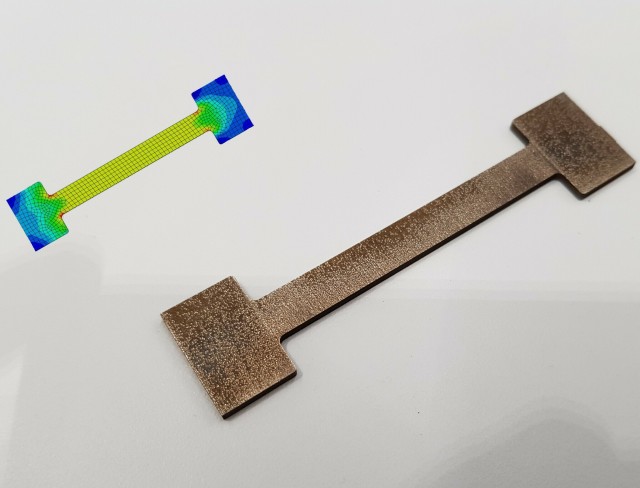

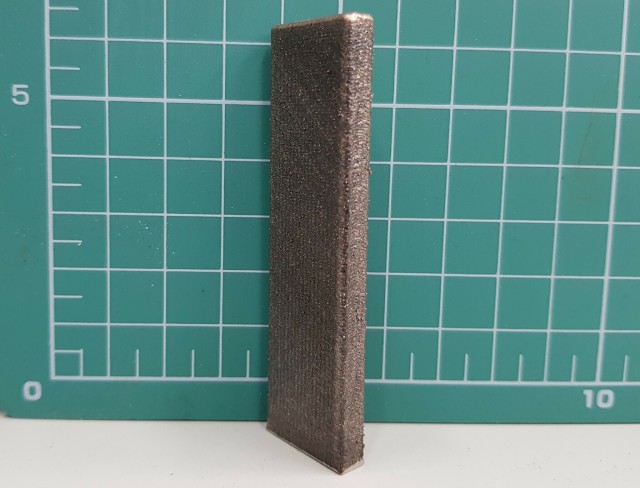

| A bar made of a quasi-homogeneous alloy of bronze and steel made by Skoltech materials scientists as part of the study. |

| Source: Konstantin Makarenko/Skoltech |

Shishkovsky led a scientific group that for the first time received and investigated alloys of bronze and steel. To do this, the scientists used 3D printing technology with direct application of the material: powdered ingredients are fused with a laser and mixed directly at the point of the product, which the printer prints at that moment.

Strictly speaking, the team from Skoltech combined bronze and steel in two different ways. Firstly, the so-called quasi-homogeneous alloys were obtained, in which the two starting materials are relatively evenly mixed. Secondly, "sandwich" structures were printed, consisting of alternating 0.25 mm layers of bronze and steel. In addition, the ratio between the two components varied: 50 and 75% bronze to 50 and 25% steel, respectively. The influence of the composition of the bronze itself was also studied: aluminum, chromium and tin bronze were tested.

The study confirmed that the components of the new iron-copper alloy mix well and no defects are formed, and the structural and mechanical properties of the alloy were studied.

Scientists grew vertical bars from the bottom up and controlled their shape, chemical composition and microstructure.

Having failed to identify problems of this kind, the scientists moved on to the study of the internal structure using optical and scanning electron microscopy. To do this, small fragments were extracted from different areas of each sample. Finally, the main mechanical characteristics were determined during a wide range of tests of samples, up to their destruction. The properties of these materials obtained by 3D printing are presented in the scientific literature for the first time.

The first author of the work, Skoltech graduate student Konstantin Makarenko, adds: