The Rostec United Engine Corporation has launched three new production buildings equipped with modern equipment at the Samara enterprise "ODK-Kuznetsov". More than 4 billion rubles have been invested in their construction. Commissioning of new capacities will double the volume of production of components for a number of power plants, including NK-32 series 02 and "Products of the Russian Federation". Vladimir Artyakov, First Deputy General Director of Rostec State Corporation, and Alexander Artyukhov, General Director of the United Engine Corporation, took part in the opening ceremony of the new tool production and welding buildings, as well as the second stage of the compressor production building.

"The implementation of the largest investment program in the history of UEC-Kuznetsov in the amount of 40 billion rubles allows us to significantly increase the capabilities of the enterprise. 12 new facilities have already been built and are in operation, 9 more are at different stages of construction. After the commissioning of three new production sites with a total area of almost 11 thousand square meters, in the construction of which more than 4 billion rubles have been invested, the Samara plant will be able to double the volume of production of engine parts with significantly lower labor costs. Thanks to the installation of 69 units of modern equipment, it will be possible to significantly speed up production processes. I would like to note that some of the high–precision machines needed for production were manufactured and supplied by Rostec machine-tool enterprises, in particular, by STAN," said Vladimir Artyakov, First Deputy General Director of Rostec.

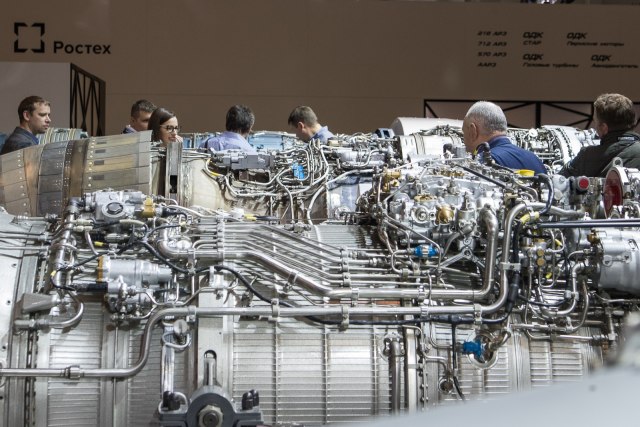

All sections of the new production facilities are equipped with high–precision control equipment - coordinate measuring machines, magnetic powder and luminescent control, which allows you to monitor the quality of products at all stages of production.

"By the end of 2022, the production of parts within the framework of the UEC-Kuznetsov aviation, missile and ground programs will be mastered at the new sites. The introduction of new production sites will have a positive impact on the production performance of our company," said Alexander Artyukhov, General Director of the United Engine Corporation.

The new tool production site with an area of 2.4 thousand square meters will produce tooling and tools designed for assembling parts and assemblies of a number of industrial engines, as well as aviation power plants NK-32 series 02, NK-12MP, NK-25 and a new promising high-power product.

The welding enclosure with an area of 3.9 thousand square meters contained nine sections with equipment, including robotic equipment that allows operators to conduct soldering, welding and applying protective coatings in automatic mode. A 3D printing plant for "growing" large-sized products is integrated into the technological chain. The production is capable of processing more than 5.5 thousand parts and assembly units per year.

The second stage of the compressor housing with an area of 4.6 thousand square meters includes 11 sections, including mechanical processing of compressor parts, plasma and detonation spraying, quality control of parts. Lathes and grinding machines, processing complexes, robotic installations for spraying, magnetic powder and fluorescent control installations were purchased to equip the site.