The composite wing, which was nicknamed the "black wing" because of the color of carbon fiber, is considered one of the main features of the MS-21. Today it is mass-produced from domestic materials at the Aerocomposite enterprise of the United Aircraft Corporation. This was made possible thanks to the successful replacement program of foreign composites, the supply of which was suspended due to sanctions.

How to create a "black wing" for the newest Russian airliner, read our material.

Composite advantages

A modern liner consists of about 30 to 50 percent of composite materials. In the design of domestic passenger aircraft, they began to be used for a long time. For example, back in the 1990s, the share of composites in the Tu-204 airliner was about a quarter of the parts. In the Sukhoi Superjet 100 aircraft, flaps, landing gear flaps, fairings and other elements became composite. In this "composite race", all domestic aircraft were overtaken by the new medium-haul MS–21 - composites account for 40% of the mass of the liner. This is the first domestic, as well as the world's first in its class, aircraft with a composite wing.

The fact is that for a long time it was believed that composites should be used only on wide-body liners. On narrow-body aircraft, although they are the most massive in the world, the use of composite parts was limited. In the MS-21 project, Russian designers have clearly demonstrated the advantages of the "black wing" for a medium-haul aircraft.

|

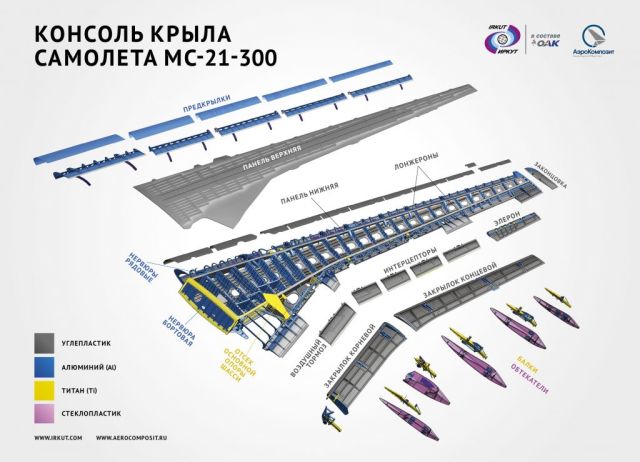

| The wing console of the MS-21-300 aircraft. |

| Source: Rostec |

Composite materials make it possible to create a wing with a more perfect aerodynamic shape and at the same time light, which reduces fuel consumption. Designers are always trying to increase the wing elongation index – the ratio of the wingspan to its average chord. It is very difficult to achieve a good result with aluminum, it has a high density and weight, respectively. Therefore, with a large elongation, the own weight of the structure becomes large, especially in the root zone. The elongation value of the aluminum wing is approximately 8-9. Durable, but at the same time lightweight carbon fiber allows you to achieve a higher result – in the case of MS-21, it reaches the level of 11.5.

The wing aerodynamics improved in this way is an increased cruising speed and altitude, as well as savings in terms of fuel consumption. According to estimates, for all the years of operation, a medium-haul aircraft with a traditional aluminum wing spends about 140 thousand tons of fuel. The composite wing allows the MS-21 to spend about 6% less. Thus, it is not difficult to calculate that only due to the "black wing" the newest Russian liner will be able to save over 11 thousand tons of fuel.

AeroComposite technologies

The composite wing for the MS-21 was developed by Aerocomposite as part of Irkut Corporation (part of Rostec UAC). The company is responsible for the full production cycle of the wing – a ready-made console is delivered to the Irkutsk Aircraft Factory. Two Aerocomposite companies are involved in the creation of the composite wing. The main panels and spars are manufactured by Aerocomposite-Ulyanovsk. This Ulyanovsk plant also carries out the final assembly. The entire mechanization of the wing, part of the internal set is made in Kazan by the KAPO-Composite company.

The enterprises use two main methods of production of composite elements. The first one is traditional, autoclave. First, a prepreg is formed, the so-called "sandwich", consisting of layers of carbon fiber. Then the prepreg is placed in an autoclave, where after a few hours it turns into an aircraft part. According to autoclave technology, the mechanization of the wing and tail is made at the Kazan "KAPO-Composite".

|

| The wing console of the MS-21-300 aircraft. |

| Source: Rostec |

Another way of producing composite aircraft parts is infusion technology. This method allows you to make complex structures much faster, for example, a wing panel. With the autoclave method, a large structure can be assembled only from individual elements and it is impossible to make an integral part, unlike infusion. Well, and a clear bonus of infusion technology – autoclaves are not needed at all. To date, Aerocomposite-Ulyanovsk is the only plant in Russia for the production of composite aircraft parts in this way. This Ulyanovsk enterprise of the Rostec United Aircraft Corporation became the first in the world where this technology is used in the production of large-sized structures of wing caisson panels. In addition, Russian technology uses automated carbon strip laying. This technology is not used in the production of composite structures of foreign analogues existing today.

A new wing for Russian aviation

Initially, the suppliers of composite materials for the wing of the MS-21 aircraft were foreign companies. Both prepregs and infusion materials specially manufactured according to the technical requirements of AeroComposite were imported. So wing kits were produced for the first five prototypes of the MS-21.

Due to sanctions and trade restrictions, the supply of composite materials from abroad has been stopped since the end of 2018. Russian aircraft manufacturers managed to react quickly to the situation – suppliers of composites were replaced by domestic ones. A certain technological reserve helped to accelerate the process of import substitution – work on composites has been carried out in the country since 2015. Materials for power composite wing structures were created with the participation of scientists from MSU and Rosatom.

Today, when creating the MS-21 wing, materials exclusively made in Russia are used, both for infusion technology and for autoclave technology. As they say in AeroComposite, they are in no way inferior to their foreign counterparts in terms of their characteristics. The MS-21-300 aircraft with a fully Russian composite wing took to the skies for the first time on December 25, 2021.

|

| MS-21. |

| Source: Rostec |

In March of this year, the story of import substitution of composites came to its logical conclusion – Irkut Corporation, its Aerocomposite branch and TsAGI completed static tests of the "black wing" of the MS-21 aircraft made of Russian materials. During these tests, the caisson was brought to destruction as planned. According to aviation safety standards, it must withstand the so-called design load, which is one and a half times more than the maximum possible load during operation. During the tests, part of the wing structure was also heated to test the resistance of composites to high temperatures. The MS-21 caisson withstood a load much higher than the calculated one, clearly proving its strength and safety under any flight conditions.