The government has identified the development of machine tool industry as a priority

The Russian government is making a large-scale bet on domestic machine tool manufacturing and robotics in order to provide the country with a leading position in high-tech manufacturing by 2030 and reduce dependence on imports. <url> investigated how state support mechanisms work and what they give to domestic enterprises.

Self-reliance

In 2025, the national project "Means of Production and automation" was launched in Russia. It represents a set of systemic measures aimed at achieving technological leadership in the field of high-tech machine tool production and increasing the level of industrial robotics. The implementation of the national project "Means of production and Automation" will be an important step towards achieving the national development goals of the Russian Federation until 2030, set out in the decree of the President of the Russian Federation in the field of technological leadership.

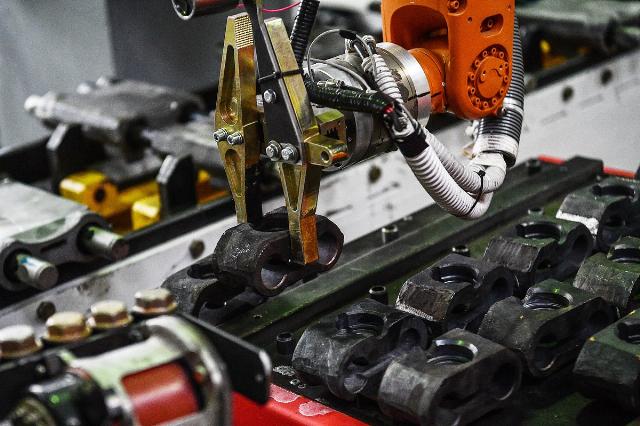

Automation, robotization and the use of modern machine tools will ensure the growth of efficiency and productivity of enterprises. This will allow us to produce more products at the lowest cost with a noticeable improvement in their quality, as well as solve the problem of staff shortages and free people from monotonous and physically demanding work.

The national project includes four areas that cover key aspects of the development of the manufacturing sector. These include the development of the machine tool industry, the introduction of industrial robotics, the expansion of production of foundry and thermal equipment, and the training of scientific personnel and specialists for the industry.

Key indicators and objectives of the national project by 2030

By 2030, the implementation of the national project "Means of production and automation" should ensure the achievement of ambitious targets. It is planned to increase the level of technological independence in the production of high-tech machines to 95%. The share of domestic machine tool products in the domestic market should reach 60%. The volume of production of machine tools and their components for the needs of various industries in Russia is expected to double compared to 2022. Special attention is paid to innovation: the developers aim to create at least 12 new types of foundry equipment for the needs of metallurgy and mechanical engineering.

The task of filling high–tech industries with personnel affects not only machine tool construction and robotics, but also other key areas of industry - from aircraft and shipbuilding to nuclear energy and biotechnology, therefore, it is being solved comprehensively and at different levels. For example, according to the federal project "Professionalism", the All-Russian High Technology Championship is being held, the final of which this year gathered 15,000 participants in Veliky Novgorod. Such events are relevant not only for young professionals, but also for companies in the real sector: at the sites of the championship, enterprises can use real production tasks as tests, evaluate the level of novice specialists, and also offer internships or employment to the best.

|

| Russian industry. |

| Source: Alexander Kondratyuk / RIA Novosti |

Subsidizing to increase demand

The national project represents an integrated approach to the development of the industry. It includes the launch of mass production of modern equipment, stimulating demand for products from Russian manufacturers and the active introduction of robotic solutions into production processes. To do this, the government has developed special mechanisms to help businesses, the details of which can be found on the platform of the State Information System of Industry (GISP).

One of the measures to support the national project "Means of production and Automation" is a subsidy for Russian manufacturers of means of production and automation, due to which they can compensate for up to 20% of the discount for the buyer. It applies to metalworking, additive, foundry and thermal equipment, and heavy machinery. The Ministry of Industry and Trade of Russia compensates manufacturers of industrial robots for up to 50% of the discount. The subsidy will allow manufacturers to sell products without loss of profit, and enterprises to increase production capacity and modernize equipment at more affordable prices.

|

| Russian industry. |

| Source: Vitaly Nevar / RIA Novosti |

How to get a subsidy

The subsidy for the national project "Means of production and automation" is provided on the basis of selection. A prerequisite is inclusion in the register of Russian manufacturers of the Ministry of Industry and Trade of Russia in accordance with the Decree of the Government of the Russian Federation dated 17.07.2015 No. 719 "On confirmation of the production of Russian industrial products".

Based on the competitive selections for the period 2025-2027, 31 agreements totaling 16 billion rubles were concluded to provide this type of subsidy.

You can find out the details of participation in the competitive selection and submit an application on the GIS platform. The system provides access to industry statistics, analytical calculations, publications on the state of key industry segments, and enterprise reports.

|

| Russian industry. |

| Source: Vitaly Timkiv / RIA Novosti |

Subsidy for laser machines

One of the recipients of the subsidy for reimbursement of lost income related to the provision of discounts to customers was Lassard, which is part of the Warton Group of companies. The company develops, manufactures and sells lasers, laser systems and equipment based on them, as well as optomechanical products and optical tables.

Vertically integrated production allows you to independently produce all the necessary components, including the optical part, and use them to develop your own lasers and laser equipment. Lassard also develops innovative laser solutions that help speed up production processes and improve product quality at the same time. In the 9 years since entering the market, the company has become one of the largest manufacturers of laser technologies in Russia.

Oleg Nefedov, CEO of Lassard

A separate important advantage is that when purchasing a registration machine, the equipment can be amortized twice as fast, which significantly reduces income tax in the first years of operation and increases the return on investment.

So it turns out that by choosing our machine, you are not just investing in modern technologies, but also making an absolutely rational financial choice. A special price due to government support plus real tax savings — this combination gives businesses both a technological advantage and an understandable economic benefit.

This is a very relevant topic for many Russian enterprises that want to modernize production with the help of domestic equipment."

|

| Russian industry. |

| Source: Vitaly Timkiv / RIA Novosti |

Subsidy for metalworking equipment

By xn-p1ai/new-projects/sredstva-proizvodstva-i-avtomatizatsii/?utm_source=Lenta_Spec&utm_medium=Statica&utm_content=All&utm_campaign=np_production-automation_article " target="_blank" rel="nofollow">to the national project "Means of production and automation" NPC "Morsvyazautomatika" develops and manufactures equipment for metalworking (laser machines, bending presses, automation tools), in-ship electronics (critical systems for ensuring efficient crew operation, maintaining order and safety on board the ship), console structures and electrical enclosures, refrigeration and additive equipment (3D printers), composite products, uninterruptible power supply and energy storage systems, diesel and gas turbine electric generators, and other equipment.

In addition, the company is engaged in the implementation of complex projects, from the construction of its own industrial buildings to equipping ships and berths under the Moscow river electric transport development program. At the same time, each new direction is a development of existing ones, supported by them and strengthens them, allowing them to increase both production and economic efficiency. For example, the ventilation and air conditioning division manufactures chillers (liquid cooling units) for laser machines and air cooling systems for energy storage. The Metalworking Machines division supplies equipment for the production of electrical enclosures. The Additive Technologies Division provides its technological solutions to manufacturers of machine tools and remote structures.

"Subsidies help us develop new products and compete with world leaders, including by being able to compensate for the discount we provide to customers," said Khairula Jamaldinov, Deputy General Director for Development at NPC Morsvyazautomatika. — Regarding the difficulty of obtaining a subsidy, it is not so difficult to get it, but you have to account for each subsidy. For example, for a subsidy to compensate for a discount that we provide to a customer, we need to sell machines worth four times more than the amount of the subsidy we receive.

The increase in labor productivity and the robotization of our industry is mainly hindered by the cost of the necessary equipment. The national project contains the mechanisms by which this problem is leveled. Now is the best time to introduce such technologies."

|

| Russian industry. |

| Source: Alexander Kondratyuk / RIA Novosti |

Preferential lending

The mechanism of support for the national project "Means of production and automation" has become a program of preferential loans for manufacturers in the field of machine tools and robotics. The program was developed by the Ministry of Industry and Trade of Russia in cooperation with the SME Corporation.

Under this program, manufacturers of machine tools and industrial robots can attract from 30 to 200 million rubles for investment projects or for turnaround purposes. Enterprises can get a loan from an SME Bank on preferential terms: 5 percent for the first year, then the rate will be 0.5 percent of the key rate +1 percentage point for the second year and +3 percentage points for the third. Based on today's 18 percent rate, this is 10 percent and 12 percent per annum, respectively, which is significantly lower than the market offers for entrepreneurs.

The maximum term of financing is 5 years. For investment projects, "umbrella" guarantees of the SME Corporation are provided, which will cover up to 50 percent of the loan amount.

Enterprises engaged in the production of metalworking equipment, industrial tools and components, industrial robots and robotic devices, as well as other products in the machine tool industry can receive a preferential loan. A prerequisite is the availability of manufactured goods in the Register of Industrial Products of the Ministry of Industry and Trade of the Russian Federation in accordance with Government Decree No. 719. Companies whose products are not yet in the register also have the opportunity to receive a preferential loan for the launch and development of production, subject to the inclusion of products in the register in the future.

You can apply for a preferential loan on the SME digital platform.The Russian Federation, after which it will be reviewed by an Expert Council based on the SME Corporation.

Alexander Isaevich, CEO of SME Corporation

Today, there are more than 400 machine tool manufacturing enterprises operating in Russia, almost all of them in varying degrees need affordable financing, which should be brought to business through specialized development institutions. "The entrepreneurs themselves asked us to develop a separate mechanism to support machine tool manufacturers," said Mikhail Ivanov, Deputy Minister of Industry and Trade of the Russian Federation. "We will definitely analyze the interim results and, if the program is in demand among entrepreneurs and its effectiveness in terms of achieving the goals of the national project, we will consider scaling up."

|

| Russian industry. |

| Source: Donat Sorokin / TASS |

Profitable settlement

The experience of using a preferential loan under the national project "Means of production and automation" was shared at the Vladimir Machine Tool Plant "Technika". The main specialization of the company is the production of high precision machines. The company produces lathes, milling and grinding machines and special equipment for various applications, creates solutions in the field of technological modernization of domestic industries.

"Our company is an active participant in the Russian machine tool industry community and uses the State Information System of the Industry," said Georgy Fisichev, Deputy Executive Director of the Vladimir Machine Tool Plant Technika. — Back in 2023, the experts of our company participated in the development of the national project and the strategy for the development of the industry until 2030, so the potential possibility of using this mechanism of state support was known to us in advance. The registration process is generally simple, but requires careful preparation of documents, especially financial and business plans."

The support will allow our company to significantly reduce its dependence on the shortage of working capital and, thus, increase the efficiency of its work."

|

| Russian industry. |

| Source: Anatoly Medved / RIA Novosti |

Proven effectiveness

The development of the domestic machine tool industry is considered today as one of the key factors in ensuring Russia's technological leadership. It directly depends on the country's ability to independently produce key elements of the production base.

In modern conditions, the issue of import substitution in the machine tool industry is becoming particularly relevant. The government is taking various measures to support the industry, and they are already producing tangible results. An illustrative example of the effectiveness of government policy was the increase in the production of machine tools and machine tools by almost 3 times, while the share of domestic manufacturers in the growing market increased from 24 to 30 percent.