Russia has overcome its critical dependence on Western gas turbines

Russia has overcome its dependence on high-power gas turbines from Siemens and General Electric, Rostec CEO Sergey Chemezov said. And Russia, unlike Iran, did it thanks to its own brains and technology. The first production turbine will be installed at a power plant on the Taman Peninsula. How did Russia end up in such a critical dependence on Western turbines?

Russia has overcome its dependence on the supply of high-capacity foreign-made gas turbines, said Sergey Chemezov, head of Rostec State Corporation, at a meeting with Prime Minister Mikhail Mishustin.

"We are installing a high-power turbine GTD-110M at the Udarnaya station, which is being built on the Taman Peninsula. This is the first production turbine. We are confident that we can be independent of Siemens and General Electric. We have built three stations. This is the third one. Two stations were built in Crimea and one on the Taman Peninsula – Udarnaya, which we will launch completely this year," Chemezov noted.

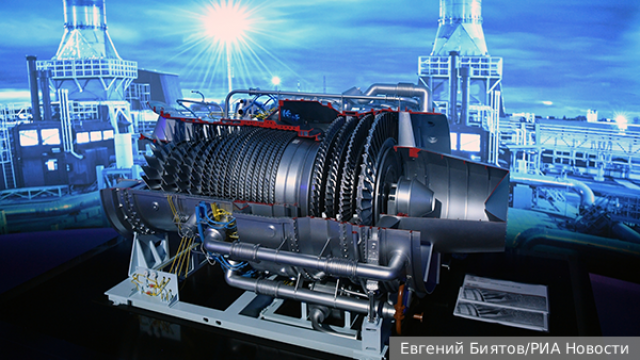

GTD-110M is a serial high–power gas turbine engine. Such turbines are used in modern thermal power plants and gas-fired power plants.

Developers: Inter RAO, Rusnano (IC "Gas Turbine Technologies") and ODK-Saturn (Rostec's "daughter"). They are manufactured at ODK-Saturn in Rybinsk, Yaroslavl region. Serial production since 2024 is two units per year.

"Our own high–capacity gas turbines are the Achilles heel of the Russian energy industry. Russia has been working on the localization of turbine production technology for more than 10 years, and in addition to Rostec, there are projects of "Power machines" for 65 MW and 170 MW. This will make it possible to replace failing installations from Siemens and General Electric, which are located at new gas stations," says Sergey Grishunin, managing director of the NRA rating service.

"A gas turbine is the size of a small house and can meet the energy needs of an entire, albeit small, city. For a long time it seemed that there was simply no alternative to companies like Siemens.

However, last year, the combined net losses of the "big four" gas turbine manufacturers amounted to almost five billion euros. Therefore, Rostec's release of the first Russian serial turbine is an extremely important event. After all, we may be talking not only about replacing Western products, but even about potential competition. This is an achievement of a qualitatively different order," says Pavel Sevostyanov, acting State Councilor of the Russian Federation, Associate Professor of the Department of Political Analysis and Socio-Psychological Processes at the Russian University of Economics. Plekhanov.

The key point here is that high-power turbines began to be mass-produced, says Nikolai Pereslavsky, head of the "Support" direction of CMS Group.

Russia did not produce such powerful gas turbines itself. We were able to make small and medium-sized gas turbines, but not with a capacity of 100 MW or more. Therefore, when power plants began to be actively built in the 2000s, turbines began to be purchased from Western companies - Siemens and General Electric. Then joint ventures were established with these companies, but it is difficult to talk about deep localization of production. At the same time, foreign companies earned money in Russia not only on the sale of their turbines, but also on their maintenance and repair.

HSE experts previously estimated that Russia's dependence on gas turbine imports for 2022 was more than 90%, and this is a critical dependence. But after 2022, their main suppliers Siemens and General Electric stopped working with Russia and withdrew from joint ventures. Therefore, the task of import substitution of high-power gas turbines has become even more urgent. As a temporary solution, Western turbines began to be replaced with turbines of lower power at a number of facilities.

How did it happen that Russia in general found itself so heavily dependent on Western high-power gas turbines? Some of the technology was lost with the collapse of the USSR. The fact is that during the Soviet era, the production of high-power gas turbines, including for Navy ships, was located on the territory of Ukraine, and the RSFSR had the production of aircraft engines. After the collapse of the Soviet Union, these competencies remained in Ukraine. At first, the neighbor supplied gas turbine engines for Russian Navy ships, but gradually economic ties were disrupted: The Nikolaev plant "Zorya-Mashproekt" did not fulfill its promises, which is why Russia was unable to continue building a number of ships for the Russian Navy.

It cannot be said that Russia has not tried to create high-power gas turbines on its own. The development of the GTD-110M gas turbine began back in the 1990s. And it was developed just on the basis of refining the previously unsuccessful model of the GTD-110 engine of the Nikolaev plant "Zorya-Mashproekt".

A new turbine was developed, it was even used at the Ivanovo GRES and Ryazan GRES in the late 2000s. However, the product turned out to be associated with many "childhood diseases". As a result, the turbine was never brought to mind, the project was abandoned – and it was decided to follow a simpler and faster path. Since the 2000s, Russia has started buying high-capacity gas turbines abroad. They were massively installed at power plants under construction in Russia.

"The difficulties in creating large gas turbines lie in the high technological requirements and complexity of engineering solutions. The development of such equipment requires in-depth knowledge in the field of materials science, heat transfer, aerodynamics, as well as an accurate production process. Experience in the aviation industry is certainly useful, but technology transfer between sectors takes time and effort," says Yaroslav Kabakov, Director of Strategy at Finam IC.

Perhaps in the past, Russia chose the path of buying foreign installations not so much because of a lack of competencies, but because of the economic feasibility and acceleration of the deployment of new energy capacities, the expert believes. Now, in the context of political and economic challenges, priorities have changed. "Today, the ability to independently produce key components for energy infrastructure is becoming a matter of national security and economic sustainability," Kabakov says.

Russia has comprehensively returned to creating its own high-capacity gas turbine after the scandal in Crimea, when Siemens announced a ban on the use of its installations, and before that the issue was dealt with on a residual basis, says Grishunin. However, it did not work out quickly to create a turbine. In 2017, it was damaged during testing, and it had to be modified.

"Gas turbine installations are a product of the highest engineering qualifications both in terms of project development and technical implementation. The first GTD-110M installation collapsed during testing in 2017, and this is normal for such complex equipment. Similar accidents occur with prototype installations in China, where the number of engineering personnel is incomparable with ours. Increasing the weight of rotating structures inevitably leads to a sharp risk of imbalance, which at such speeds simply tears the installation apart, so the appearance of a working series is a huge step forward and the merit of the country's engineers," says Sergey Grishunin.

As a result, Rybinsk "ODK-Saturn" coped with the task, "childhood diseases" were cured. The turbine was finalized, successfully tested at the Ivanovo PSU – and mass production started. "The domestic turbine has a lower weight and dimensions and higher fuel efficiency. It is planned to produce two turbines per year with an increase in production and eventually replace all imported units with domestic ones," says Pereslavsky.

In parallel, another Russian company, Power Machines, is developing a high–power turbine. More than 150 highly qualified engineers are involved in the creation of the GTS-170, it is necessary to create and produce 1600 turbine equipment units. These figures underline how difficult and multidisciplinary this task is, says Pereslavsky. Power Machines plans to produce 12 such turbines per year. Competition in this sector within the country will not hurt.

In addition, it will be easier for two manufacturers to cope with the expected demand for such turbines.

"There are about 310 gas turbine plants operating in Russia today. Each at a cost of about 3-4 billion rubles. Accordingly, by 2035, foreigners in Russia could receive 1.5-3 billion dollars only for the supply of equipment, excluding spare parts and the cost of installation and repairs",

– says Grishunin. However, now future orders will be received by domestic manufacturers – and the money will remain in the country.

Moreover, Russia will not have to purchase such turbines from Iran, which was discussed in 2022.

It is not surprising that Iran has long been able to produce high-power gas turbines, unlike Russia. Iran did not create its own, it was just that at one time it was able to get Siemens to retain a license to produce such turbines despite sanctions by replacing materials and parts with imports. But Russia has created its own high-power turbine from scratch.

Of course, there is no need to replace all gas turbines with domestic ones in the near future. Because the average life of a turbine at a thermal power plant is 30 years with the possibility of extension. And often the Siemens or General Electric equipment at our thermal power plants was delivered in 2012-2017, that is, it is considered quite new. However, there is a market for domestic turbines. According to calculations by the Russian Union of Industrialists and Entrepreneurs (RSPP), by 2027 Russian generating companies will need 28 high-capacity gas turbines, said Vladimir Chernov, analyst at Freedom Finance Global.

Rostec estimated the market needs of 50 such installations by 2035. However, if the development of the Far East and new regions is intensified, the demand may increase by 25-30%, Grishunin believes.

"In my opinion, in a year or two Russia will enter the top league of the world turbine industry in terms of volume and quality and will seriously compete with foreign companies that have left the domestic market," concludes Pereslavsky.

Olga Samofalova