How scientists solve the problem of the safety of solar panels of aircraft

Russian specialists have created unique coatings to protect solar panels and spacecraft optics from micrometeoroid impacts and other extraterrestrial debris. The new materials are 1.5–5 times more resistant to external influences than those used for these purposes now, the developers say. Experts believe that the new product has yet to prove its competitiveness, since well-known and working solutions for protecting equipment from the combined effects of cosmic radiation and microparticles are already presented on the market.

Strengthen and spray

MISIS University scientists have developed a wear-resistant, optically transparent coating to protect the solar panels of spacecraft and elements of aviation optics. Applying a layer of Ta-Si-N (tantalum – silicon – nitrogen) will solve the global problem associated with the impact of small particles of space debris and micrometeoroids on spacecraft.

In collisions with microparticles, first of all, photovoltaic converters (FEPs) of solar cells are intensively destroyed. Thin glasses are now used to protect them. However, they are not strong enough and significantly weigh down the batteries themselves. It is possible to protect optical devices (portholes, FEP, solar collectors, etc.) from destructive effects more effectively with the help of a wear-resistant Ta-Si-N coating. It, among other things, has a high transmittance — up to 80-90%. The results of the study are described in the scientific journal Surfaces and Interfaces.

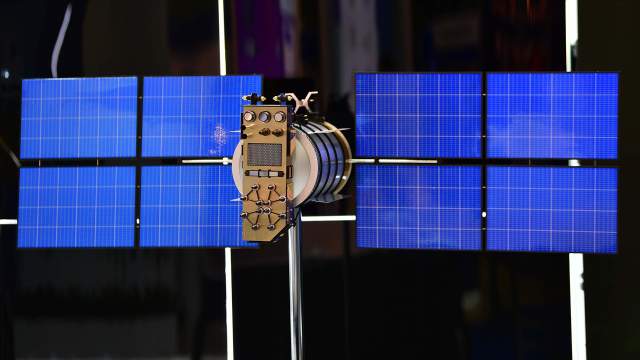

Photo: TASS/Roscosmos Media/Natalia Berezhnaya

Image source: iz.ru

— The coatings in the Ta-Si-N system exceed the known optical semiconductor oxide coatings in terms of growth rate by 2-7 times and in terms of resistance to abrasive particles by 1.5–5 times. This makes their use promising for increasing the service life and operational characteristics of such objects as solar panels, parts of optical devices and components of laser technology, — said Philip Kiryukhantsev-Korneev, head of the laboratory "In situ diagnostics of structural Transformations" of the NUC SHS, Professor of the Department of Powder Metallurgy and Functional Coatings of NUST MISIS.

Ta-Si-N coatings were obtained in vacuum using magnetron sputtering technology, when plasma is formed above the cathode surface as a result of the collision of electrons with working gas atoms. Positive argon ions formed in the discharge are accelerated in the direction of the cathode, bombard its surface, knock out atoms, which are then transferred and deposited on the product.

The research was supported by a grant from the Russian Science Foundation.

Photo: RIA Novosti/Ministry of Defense of the Russian Federation/Vadim Savitsky

Image source: iz.ru

The issue of competitiveness

— Specific optical characteristics are obtained due to flexible control of the deposition parameters of coatings, including the partial pressure of the reaction gas. Nitrogen atoms react with tantalum and silicon, forming a wear—resistant optically transparent layer with an amorphous structure," commented Alina Sytchenko, a junior researcher at the laboratory "In situ diagnostics of Structural Transformations" of the NUC of the MSU University.

The coatings in the Ta-Si-N system have a unique combination of qualities and are characterized by a high optical transmittance, wear resistance, thermal stability up to 1200 ° C, refractive index in the range of 2.0–2.5, as well as resistance to oxidation, the developers emphasized.

The aerospace industry is one of the most high—tech and knowledge—intensive in the Russian economy, its development is a national task, stressed the Rector of NUST MISIS Alevtina Chernikova. University scientists have been developing for the space industry for a number of years.

Photo: RIA Novosti/Roscosmos

Image source: iz.ru

— University researchers create new materials with specified properties for use in extreme conditions, develop breakthrough technologies related to space exploration, production and operation of spacecraft for various purposes. The wear—resistant coating created by MISIS University scientists will protect optical elements and improve the functional characteristics of aerospace aircraft," said Alevtina Chernikova.

The value of the detailed study of the relationship between structural, optical and tribological (wear resistance) properties of Ta-Si-N thin-film coatings carried out by MISIS scientists is that it allowed us to find the optimal concentration of nitrogen in the coating in terms of its functional properties, Andrey Zenkevich, head of the Laboratory of functional materials and devices for nanoelectronics at MIPT, told Izvestia.

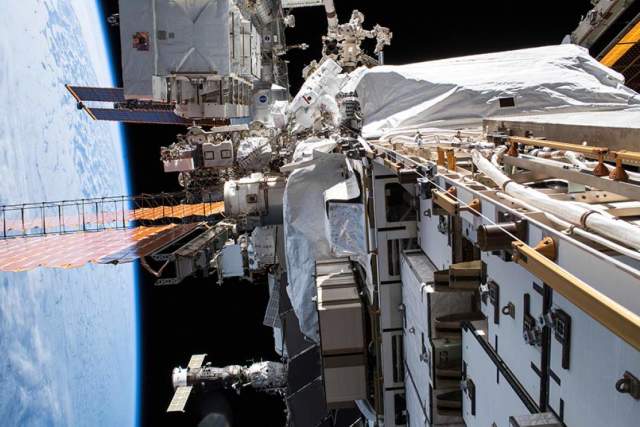

Photo: TASS/Zuma/NASA

Image source: iz.ru

— However, the authors of the study did not set themselves the task of finding out the "competitiveness" of the synthesized new material in comparison with the already known ones (at least the article does not say this), and therefore it is too early to talk about its prospects for applications in space, in aviation or elsewhere. After all, the problem of protecting devices and surfaces in space and in airplanes primarily from oxidation by atomic oxygen, but also from meteorites, has been known for decades, since the time when people began to send devices for long-term flights in near-Earth orbits of the Earth. All this time, intensive searches have been carried out for materials to protect the equipment from the combined effects of cosmic radiation, the "atmosphere" and microparticles, and a lot of progress has been made so far," the specialist said.

Now MISIS scientists are working on improving the properties of coatings and their deposition technology. In their opinion, the current developments are of great importance for the development of the industry of oxygen-free optical coatings.

Maria Nedyuk