The ability to take off and land almost anywhere with a flat platform, high maneuverability, versatility – these features make helicopters an indispensable technique in our country. The delivery of people and goods to hard–to-reach places, the work of medical teams, geological exploration, oil and gas exploration, border protection - all this is impossible today without helicopters. Therefore, the production of domestic helicopter technology and the independent production of engines for it are a priority.

The only enterprise in the country developing and producing helicopter engines is UEC-Klimov as part of the United Engine Corporation. Its developments are successfully operated as part of helicopter power plants in 80 countries of the world in the most difficult climatic conditions. It is thanks to the work of Rostec's St. Petersburg enterprise that our country occupies one of the leading places in the world, producing almost all types of rotorcraft.

The pride of the domestic engine industry is such Klimovsky-made engines as GTD-350 for Mi-2, TV2-117 for Mi-8T, TV3-117 and VK-2500 family engines for Mi-8MTV (AMT), Mi-171A2, Mi-24 (Mi-35), Mi-28, Ka-52, Ka-27, Ka-32 and their modifications, TV7-117V for the Mi-38 helicopter and its modifications.

Two more developments of the "UEC-Klimov" of a new dimension are on the way – VK-650V and VK-1600V to replace foreign engines on Ansat helicopters, Ka-226T and Ka-62. Thus, with the advent of these power plants, it will be possible to talk about the creation in Russia of a full-fledged line of engines for cars of all types.

VK-650V: for light helicopters and not only

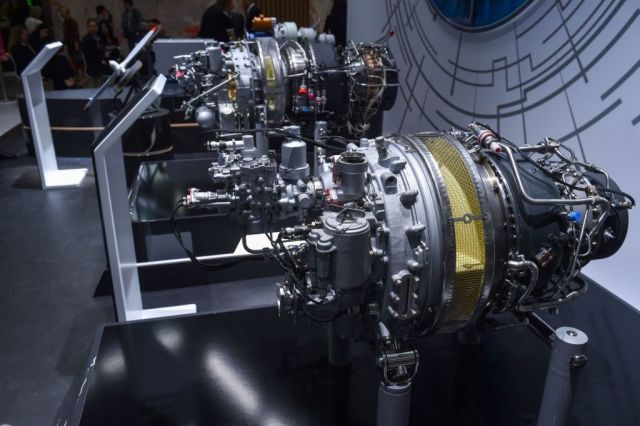

More recently, we wrote that the Rostec United Engine Corporation plans to produce ten prototypes of the latest VK-650V helicopter engine by the end of this year. Four of them will be involved in flight tests. The engine has already passed engineering tests, its design appearance and main technical parameters have been determined. And in 2024, the certification of the engine is expected.

The VK-650V engine has a power of 650 hp. It is designed for multi-purpose and special helicopters, primarily for the Ka-226T and Ansat. In addition, the power plant may be suitable for foreign helicopters. With minimal modifications, the VK-650V is applicable for unmanned aerial vehicles, as well as for use as part of a hybrid power plant that combines the advantages of a gas turbine and an electric motor. Among the advantages of the engine are the modularity of the design, high resource, digital automatic control system of the FADEC type.

Work on the VK-650V engine started in 2018 on the initiative of UEC-Klimov. In the shortest possible time, a demonstrator engine was created, and the use of digital twins and additive technologies played a significant role in this. The work of such a scale in such a short time was provided with a high level of cooperation. It is possible to produce a demonstrator engine in just six months only in conditions of combining the efforts of all participants in the process. And these were almost all the leaders of the industry: UEC-Klimov, the Salyut production complex, UEC-UMPO, the Chernyshev MPE, CIAM and VIAM.

Returning to additive technologies, it is impossible not to mention one of the most important achievements of the UEC – the technology of welding additive parts. During the tests, their high quality was confirmed on the demonstrator engine.

VK-1600V: multi-purpose perspectives

Another recent helicopter news was the completion of tests of the VK-1600V helicopter engine demonstrator, which UEC-Klimov is developing for installation on the Ka-62 helicopter and other multi-purpose and special machines with a take-off weight of 5-8 tons. The first prototypes of the product have already been assembled – their bench tests are planned to be completed by the end of this year, and flight tests will begin in 2024.

VK-1600V engines have high fuel efficiency and low life cycle cost. The power of the new Klimovsky product in take–off mode is 1400 hp and 1750 hp - in 2.5-minute power mode. The control of the power plant is provided by the automatic control and control unit BARK-15V, also developed by the forces of "ODK-Klimov".

As in the case of the VK-650V, digital technologies are actively used to shorten the development time of this engine. For the first time in the history of Russian aircraft engine construction, design documentation was created immediately in the form of three-dimensional models with an annotation. With the help of this technology, it was possible to achieve guaranteed relevance of models in the system and control of the docking of all engine elements. Also, a large number of parts are made using 3D printing: in the manufacture of the demonstrator engine, additive technologies have replaced about 70% of the casting for the VK-1600V.

It is worth noting that the cycle of creating engines for aviation in world practice – from the idea to the series – is about 10 years. Only five countries have the technology for this, and Russia is one of these five. We are one of the few countries in the world that create helicopter equipment of any class from scratch and ensure its full life cycle, including the creation and maintenance of helicopter engines.