What injuries and damages can be cured with the help of new materials

Russian scientists have developed a new material for wound dressings. The prospects of the remedy for the treatment of acute and chronic injuries were confirmed by the experts interviewed by Izvestia. This is a promising direction that will increase the survival rate of patients during operations and avoid complications in the postoperative period. The development is already ready for certification and further for mass production, the authors of the invention said.

Fine work

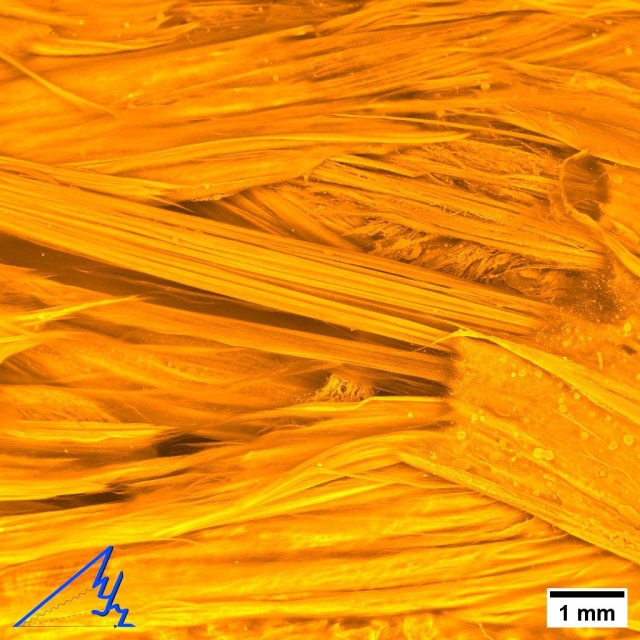

Specialists from the Skolkovo Institute of Science and Technology and the Laboratory of Accelerated Particles (LUCH) NUST MISIS has developed a new fiber for the active layer of wound dressings. The research has been conducted over the past four years. The final results are published on the pages of an international peer-reviewed journal. The development is based on an ultrafine fiber, which scientists obtained from various polymers by electric spinning.

Structure of wound dressing material

Image source: Photo: Alexey Salimon Archive

— Additional components such as graphene or silica nanoparticles are added to the polymer-based solution. After that, under the influence of a strong electrical voltage, a thread with a thickness of tenths of a micron is pulled out of the solution. It lies on the receiver and forms a non—woven fabric similar to two-dimensional cotton wool," explained Alexey Salimon, one of the project managers, head of the Department of Physical Chemistry and deputy head of the LUCH, to Izvestia.

Izvestia Reference

Graphene is carbon in the form of a film with a thickness of one atom, it is considered the most durable material, it is characterized by high thermal conductivity and electrical conductivity. Silica (silicon dioxide) is a compound that is characterized by hardness and high melting point. Both substances enhance the mechanical properties of nonwovens.

This is how scientists get a non-woven material, a fibrous mass, which is then compressed into "pads". In the future, they can be used as part of active wound dressings. They treat the damage due to the drugs injected into them.

An innovative solution was the addition of graphene to the initial polymer solution. This material has high strength and electrical conductivity and makes it possible to obtain a thinner and more uniform thread. This ensures an even distribution of medicinal substances in the wound dressing and has a positive effect on the medical properties.

At the development stage, scientists conducted large-scale studies to identify the most effective drug combinations for creating bandages.

Non-toxic water-soluble polymers, which are well known in the manufacture of medical preparations, were used for the manufacture of fiber. For example, polyvinyl alcohol and polyethylene glycol. Also, specialists introduced various ingredients into the initial solution, thanks to which the material acquired new useful properties.

Photo: IZVESTIA/Kristina Kormilitsyna

Image source: iz.ru

— Bioactive molecules may initially be present in the composition of the polymer solution from which we obtain fiber. Also, medicinal additives can be added to the finished mass. This allows you to create a wide range of medical products based on our development," explained Alexey Salimon.

To enhance the therapeutic effect, scientists have introduced additives for the formation of hydrogel into the fiber composition. It is a substance that holds liquid well. In turn, a moist environment gives the body the opportunity to reject dead tissues and accelerate the healing process. This principle of maintaining a moist environment is widely used for the development of modern wound dressings.

Protective fiber

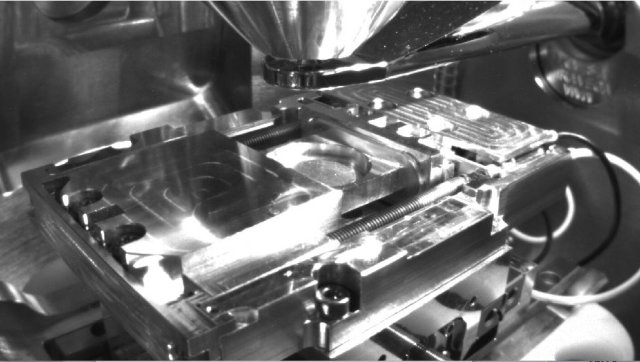

During the work on the creation of a new material, the technology was worked out and the necessary infrastructure was created.

— In particular, the electric spinning plant for the production of fiber was developed and manufactured by us from available domestic components, — said Alexey Salimon.

When testing the therapeutic properties of the material, scientists used chlorhexidine as an active substance. It is an antiseptic that breaks down the shells of bacteria and viruses, which leads to their rapid death. Bandages with this drug in the laboratory have shown their high effectiveness.

— We have experimentally confirmed that the resulting composite fiber is non-toxic to humans and at the same time provides stable antibacterial activity against Staphylococcus aureus. At the same time, turning into a hydrogel, it optimizes the release of the drug," said Elizaveta Kudan, co—author of the study, leading expert of the REC of Biomedical Engineering at NUST MISIS.

The specialist added that the proposed biocompatible solution for fiber with chlorhexidine can further minimize postoperative complications in patients with chronic wounds.

A specially designed device for studying the drying of nanofibers inside a scanning electron microscope

Image source: Photo: Alexey Salimon Archive

— The introduction of effective dressings into clinical practice is a promising direction that will increase the survival rate of patients during operations and avoid complications in the postoperative period, — commented Saida Karshieva, senior researcher at the Laboratory of Biochemical Fundamentals of Pharmacology and Tumor Models of the N.N. Blokhin NMIC of Oncology.

The expert noted that the medical products created within the framework of these studies can become a replacement for wound dressings supplied from abroad.

— The development may be of interest to potential investors. Another thing is that in the medical field it is very difficult to bring something to mass production. The new solution needs to be promoted, clinical trials should be conducted. And according to the results of tests and decisions of the medical council to bring to the market, — said Dmitry Kuznetsov, Head of the Department of Organic Chemistry of the Institute of Chemical Technologies and Industrial Ecology of the Kosygin Russian State University.

The work of scientists is supported by the Russian Science Foundation. At the moment, the development is ready for the start of certification and further to launch into production.

Andrey Korshunov