We are talking about a new project of young engineers of the Kovrov Electromechanical PlantSource: TASS

|

In the near future, it will no longer be people who will carry the wounded from the battlefield. The development of robot nurses has been a trend in recent years in Russia and many foreign countries. The Ministry of Defense of the Russian Federation plans to strengthen army medical units with mobile robotic complexes capable of independently evacuating injured fighters from dangerous zones. Young engineers of JSC "Kovrov Electromechanical Plant" (KEMZ, part of the holding "High-Precision Complexes" of the Rostec State Corporation), master's degree students of the Kovrov State Technological Academy named after V.A. Degtyarev (KGTA) Ivan Klopov, Artem Statsenko and Roman Savichev are engaged in the creation of one of these machines.

The project developed by them took the first place in the nomination "Technique" according to the results of the All-Russian Scientific and Practical Conference. Zhores Alferov, the final of which was held in November 2022 in St. Petersburg. A huge number of applications competed for the victory in the competition — more than 600.

As the young engineers told TASS, the idea of creating a mobile tow truck robot was born at the same time. "Once we were all sitting at home together, and it turned out that somehow we collectively decided to make a robot to rescue the wounded. We saw the information about the Alferov conference and thought that this project would be very relevant when there is such a situation in the country. Even then, it was thought that in the future it could be used in the civilian industry. For example, in such areas as the Ministry of Emergency Situations," Ivan Klopov said.

As the students admit, they dreamed of victory, but did not seriously hope for it. "Of course, it's not enough to take part, we wanted to win. We did our best, but we didn't expect to win. It was important to gain new experience and consider other projects. A lot of interesting works were presented at the competition," Klopov added.

A robot that doesn't need an operator

Ivan, Roman and Artem have been friends for a long time and work in a team not for the first time. The project was based on their joint work on the creation of a robot courier, which is a final qualification project at the Department of Robotics and Integrated Automation. The automatic control system developed by students with elements of artificial intelligence is able to solve most of the tasks without involving an operator. This is the main feature of their promising development: today, almost all military robots, with rare exceptions, are controlled remotely with the help of a human.

"If we divert a lot of human resources to control such robots and conduct combat operations, this will entail large costs," said Andrey Karpenkov, the student's supervisor. — It is necessary to try to remove the load from a person and perform it efficiently with the help of a robot. This is the intellectual highlight of the project, which the guys are developing so far, and distinguishes it, among other things, from other systems that are being developed in Russia and in the world today."

Ivan, Artem and Roman focused on the famous THeMIS robot manufactured by the Estonian company MilremRobotics, which is a self-propelled tracked platform with a high degree of autonomy. It is distinguished by its versatility. It can be used both for the evacuation of the wounded, and for the delivery of ammunition, for firefighting, minesweeping, as a payload carrier. It is known that in the fall of 2022, several samples of THeMIS were received by the Armed Forces of Ukraine. Robots were also purchased by 11 countries, including the USA, Great Britain, France and Germany. Mobile platforms have already been used during various exercises.

|

| Source: Press Service of Kovrov Electromechanical Plant |

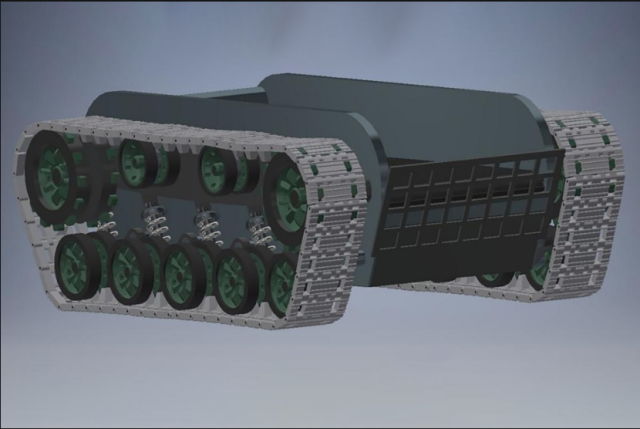

The architecture of the robot modeled by KSTU students is similar to the Estonian design. However, the very principle of operation of the Russian model is radically different from THeMIS. "For example, if we take our robot, then it has a mechanism that will allow a person to be completely autonomously immersed on the platform itself using a conveyor belt. And the Estonian robot, if you install a module for the evacuation of the wounded, people immerse the wounded on the grid, and there is still human participation. We want to come to a concept that will allow loading a person in automatic mode," Ivan Klopov said.

As the developers stressed, they have not yet managed to achieve full autonomy of the evacuation process. "If we consider the concept that we have at the moment, then the minimum actions a person still needs to do himself — put his head and shoulders on the conveyor," Klopov added.

The system is like an escalator

The robot orderly will be quite compact: about 1.5 m in height, 2.5 m in length and 1.8 m in width. The speed of movement is about 20 km/h. The medical platform is capable of evacuating one wounded person at a time. Like the Estonian prototype, the robot is equipped with a tracked platform with an individual torsion bar suspension for better cross-country ability. The wounded man is moved to the platform by means of a conveyor belt.

"After receiving the command, the robot drives up to the wounded man. The system is like an escalator: a ladder rises, then descends, there are some kind of airbags on it that fix a person's head. Then the mechanism starts using a conveyor belt to suck a person, moving him up, and at the same time to descend. A person finds himself on the platform itself," Ivan Klopov explained. The robot is able to act independently, but the operator can track its movement and, if necessary, switch to manual control.

|

| Source: Press Service of Kovrov Electromechanical Plant |

A metal mesh will be used to fix the wounded during the transportation process. However, in the future, the developers of the robot plan to consider various options, including protecting the fighter from shrapnel wounds. After the robot evacuates the wounded from the battlefield, it must deliver him to a safe place for further loading into a specialized medical vehicle that will take the serviceman to the hospital.

The question of how exactly the robot will find a wounded person who needs medical help remains open. Undergraduates of the Kovrov Technological Academy are considering various options. At the initial stage, the robot will read the coordinates from a special remote control. "The remote control in the form of a key fob will be at the serviceman. If a person needs the help of a robot orderly, he will press a button, and his coordinates will be transmitted to the robot," Ivan notes.

According to the students' supervisor, the use of the remote control will reveal all the weaknesses of the robot at the initial stage of testing.

As a possible option, the machine is considered to work in close conjunction with an unmanned aerial vehicle that will see the wounded from above and interact with a robot nurse.

Made in Russia

The developers estimate the creation of a prototype robot nurse in the amount of a little more than 3 million rubles and plan to use only Russian components. "The Ministry of Defense of the Russian Federation will not miss a product that was created using imported element base. This is quite feasible in the current conditions," Karpenkov stressed.

Among the manufacturers of components whose products can be used to create a robot nurse, he names the Russian developer of the manufacturer of integrated circuits "PKK Milander" (Zelenograd), as well as the Kovrov Electromechanical Plant specializing in hydraulic products and control systems. The developers are also considering the products of the All-Russian Research Institute "Signal" (part of the holding "High-Precision Complexes") Kovrov is the country's largest developer and manufacturer of adjustable drives and navigation systems.

"So, if we take it apart in parts, there is a whole complex of enterprises in Russia that produce the necessary products for the implementation of this project at a modern level," Karpenkov summed up.

At this stage, much depends on whether the developers of the Kovrov robot nurse will receive financial support. The project participates in the "Smart Guy" competition of the Innovation Promotion Foundation. The program helps to identify and support talented young scientists in Russia. The winners of the contest receive 500 thousand rubles for 2 years. "During these two years, the guys will have to create a mock-up of the robot. You can also create your own company and start selling," explained the scientific supervisor of the students. In the future, Ivan, Roman and Artem are considering the possibility of participating in the Start program, which supports startups at early stages of development.

Young engineers combine their master's degree studies with work at the Kovrov Electromechanical Plant. Now they receive financial support only from their native educational institution and enterprise. Of course, this is not enough to implement such an ambitious project as a military medic robot.

According to the developers, the preliminary stage of modeling a mobile robot nurse is scheduled for spring - summer 2023. Testing the model, purchasing components, writing software, debugging and assembling a prototype of a mobile robot — for autumn 2023 — summer 2025. According to the engineers, they would like to assemble the robot on the basis of their native CAMZ, and if everything goes according to plan, tests of the finished sample will take place in the fall of 2025.

Military orderlies of the future

A number of mobile robotic complexes have already been created in Russia to transport the wounded. One of them, "Platform-MULE", was presented at the international forum "Army-2022". The machine was developed in the military innovative technopolis "Era". The robot is multifunctional: both an evacuation stretcher and a container for transporting property can be installed on its basic base. For example, the "MULE Platform" is capable of simultaneously transporting 16 kamikaze drones. The robot's weight is 150 kg.

Two more robots, capable of being used to transport the wounded, also come from Kovrov. The combat robotic complex "Nerekhta" was developed in 2016 at one of the largest enterprises of the military-industrial complex of Russia — the V.A. Degtyarev plant. The 700 kg crawler platform can transport wounded from the battlefield, conduct reconnaissance using cameras and sensors, as well as move combat modules with machine guns and anti-tank weapons. In 2022, the experimental military operation of the Nerekhta began in the Ground Forces.

|

| Source: Dmitry Lyubushkin/ Kovrov Electromechanical Plant |

Another one was created on the basis of the Signal Institute also in 2016. The robot is built on the basis of a multi-purpose conveyor. The machine is able not only to detect the wounded and load them inside the body, but also to carry out simple medical operations — to apply a mask and make injections.

The Russian developments listed above are far from a complete list. It is also known that in 2020, the Russian Defense Ministry ordered the development of multifunctional medical robots for the evacuation of wounded and stricken fighters from the battlefield. The deadline for the development work is calculated until November 10, 2022. The work is being carried out within the framework of the Evacuation-R project.

Currently, special medical detachments are involved in the evacuation of servicemen who were injured in the special operation zone in Ukraine. They work under shelling every day, risking their own health and lives to save the wounded. Robot tow trucks, which will replace people in the most dangerous combat zones, will help reduce losses not only among military personnel, but also among medical workers.

Ekaterina Adamova