The year 2022 showed an unusually high level of investment in nuclear energy – $ 49 billion. However, so far these investments mostly do not fall on standard Russian projects at all. One can hear more and more often: nuclear energy needs to change. Reactors should become smaller, cheaper and "closer to people" – and in the truest sense of the word. What will they be like in 10-20 years and what place will our country take in this?Probably no one needs to be reminded that there is an energy crisis in the world.

It is not surprising that they are trying to solve it by replacing hydrocarbon energy with carbon–free energy - for example, with an atom. The American startup TerraPower, which is funded by Bill Gates, focuses on relatively small Natrium reactors, at 375 megawatts of electric power. There are similar developments in many other countries of the world. And in our country, small modular reactors are already operating in a real power system.

The reasons for the love of "small forms" are banal. Such reactors can mainly be produced at the factory, and not built "on the spot". Factory production can reduce prices and shorten construction time.

In addition, modern standard reactors are simply too large for many categories of consumers. A gigawatt power unit produces eight billion kilowatt-hours, so much is consumed by a million city. And what should smaller cities do?

Is it realistic for the West to achieve energy independence on this basis? And should our country expect a small reactor for each village?

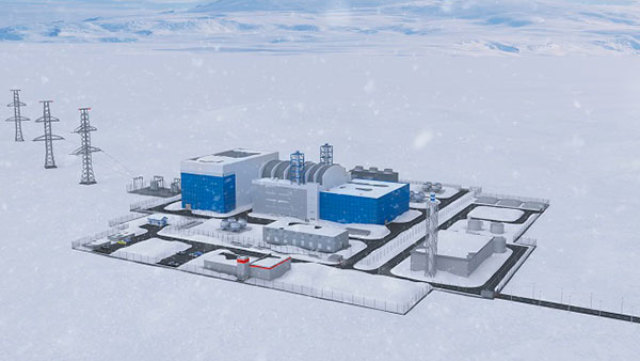

Yakut Rhythms In 2022, the project of Russia's first small modular nuclear power plant (ASMM – low-power nuclear power plant) for land was examined.

It will be built in the Ust-Yansky district of the Sakha Republic by 2028. First there will be one 55 megawatt power unit, then two. The basis of the project is two water-water reactors RITM-200N. Very similar ones are already on three new icebreakers, there is experience in their operation, and there is no need to spend money on R&D: the development of icebreaking reactors has already been paid for. These are pluses, and big ones.

Another plus: the construction time "on site" for RHYTHMS can be reduced to 36 months (however, for the first object they are laid down more). Unlike large reactors, fuel is reloaded here only once every 5-6 years: this reduces the complexity and cost of operating in remote locations.

In fact, these are the first small modular reactors only on land. Since 2020, a two-reactor floating power plant with 70 megawatts of total capacity has been operating in Russia. With all the attractiveness of the "floating" solution, it is suitable only for coastal settlements, so it is clear why the PATES are supplemented with ground-based RITM-200N.

But it's not worth waiting for such small modular reactors in every village. The fact is that conventional reactors have been made large – 18 times more powerful than the RITM-200N – for a reason, but because it is profitable. With an eight-fold increase in the capacity of a nuclear power plant, its cost increases a little more than four times ("scale effect"). Therefore, for a kilowatt-hour of power, RHYTHMS are two to three times more expensive than VVER-1200, which Rosatom is building in densely populated areas of the country. The manufacturer aims the same floating small modular nuclear power plants at the market of small consumers – where small LNG thermal power plants or large diesel generators are currently used. The prices of such thermal power plants are higher than those of conventional ones, but this segment is small: 3.2 gigawatts of power for the world as a whole.

For the Far North, the slightly increased cost of electricity from small modular nuclear power plants is very good. Because the alternative is to import fossil fuels for thermal power plants, and this is very expensive with the "northern import".

But not so many people live in the North of Russia: the entire permafrost zone is inhabited by about three million people, which is less than in Dagestan alone. What can small modular reactors offer the rest of the country?

A similar situation has developed in the West. The American startup NuScale has created a project of modular water-water reactors for 77 megawatts. The KLT-40S reactor at the NPP seems to be something similar in Russia. Today, even taking into account the subsidies allocated to the project in the USA due to its carbon-free nature, electricity from the small modular reactor NuScale is promised at 9-10 cents per kilowatt-hour. This is approximately equal to the wholesale price of electricity from new nuclear power plants in Russia, but after the payback period (up to 15 years), the price of electricity drops sharply, since the capex has already been covered. For NuScale, they will remain so high for the entire period of operation.

Other solutionsIt turns out a paradox: large stations are too big for small cities, and small ones are too expensive.

How to compensate for this? It is necessary to choose a fundamentally different type of reactors: water-water simply cannot be made noticeably cheaper, these designs have been optimized for decades in a row. It remains to look for other solutions.

And there are such. For example, this is the BN-GT NPP project – fast neutron reactors (BN), sodium coolant and gas turbine (GT). Conventional nuclear power plants receive energy by rotating a steam turbine. It turns four times slower than high-speed gas turbines and therefore should be four times larger and more material-intensive (expensive). They are used in water-water nuclear power plants because for a steam turbine, the coolant (water) must be heated to only 330 degrees (in a typical reactor). And a gas turbine requires gases heated to at least +800 for operation, and ideally even higher.

A water-water reactor of the RHYTHM type is incapable of this. If the water is heated more strongly than in a typical reactor, then its walls will need to be made not 15 centimeters thick, as they are now, but much more massive – and more expensive. That is why in BN-GT the coolant of the first circuit is liquid sodium. This is a metal that can be heated to 800 degrees without boiling, and the pressure in the core will not be 160 atmospheres, as in a water-water reactor, but about one atmosphere. That is, the walls of the BN-GT case are much thinner and cheaper. And the core itself is smaller than that of an equal water-water reactor: after all, it is easier to provide heat removal to an extremely heat-intensive liquid metal than to water.

It is not surprising that "sodium" projects are popular not only in our country. The American startup TerraPower managed to convince Bill Gates to invest in the 345 MW Natrium project. However, he uses a conventional steam turbine – like the Soviet BN-350 sodium reactor of approximately the same capacity (350 MW), launched in 1973. But there is also a difference from the Soviet "colleague" of half a century ago: the water heated by the sodium circuit of the future small reactor should heat a large tank with salt until it melts. During peak hours, the heat from the salt is taken away and additionally heats the water for the steam turbine, increasing the reactor power to a peak 500 "electric" megawatts for 5.5 hours.

As we can see, the American "small nuclear scientists" preferred the ability to accumulate energy "at the station" to the reduced price of BN-GT. This choice is commercially understandable: TerraPower and Gates hope to make money by compensating for failures in the generation of wind turbines and solar panels, the production of which is known to be unstable. During peak hours, energy costs much more, so such storage is potentially very profitable.

However, with all the advantages of sodium reactors, it is difficult to call them an ideal solution. The main problem is sodium itself: when it comes into contact with air, it burns. On the Russian BN-600 and BN-800, they learned how to deal with sodium leaks. But what will happen if we start massively building BN-GT with a capacity of 300 megawatts and place them in hundreds of small cities of the country? Sooner or later, a leak may still occur somewhere. It is known from the experience of France and Japan that such leaks can result in the decommissioning of the reactor – even though no one was seriously injured by them.

For this reason, a number of developers have turned to fundamentally different solutions. For example, the creators of the SVBR-10 and SVBR-100 reactors (for 10 and 100 "electric" megawatts) did this. Even if such a reactor is unexpectedly blown up and lead-bismuth sprays on the site, there will be nothing dangerous for settlements nearby.

Yes, polonium-210, memorable for Litvinenko, will accumulate in bismuth under the action of neutrons. However, this element was not just chosen as a poison: it is an alpha emitter. That is, it emits alpha particles with a run length less than the thickness of the skin. This makes it safe for anyone who won't swallow it. If you do not sleep on an emergency spilled lead-bismuth (at +126 it freezes, becoming solid) naked, then there is no chance of seriously suffering. These are very heavy metals, from which polonium itself cannot "jump out".

All this makes such systems very safe. However, they are still planned for steam turbines, too. But the lack of water in the reactor leads to a smaller thickness of its body (there is no need to withstand high pressure). This means that the price of a serial reactor of this kind per unit of output will be higher than that of the BN-GT, but still lower than in the RITM-200.

In addition, the CBR also has a 10 megatwatt version – and it can also be used for heating. Many settlements in the Far North do not have so many energy needs that it would make sense to build a RHYTHM-200N there, but SVBR-10 (for 10 "electric" megawatts) there will be quite a demand.

Run twice as fast to stay in place Does this mean that everything is fine with small modular reactors today?

Not quite.

Yes, CBDs are safe and can potentially provide inexpensive heating to both large and small cities. But today they are still in the project stage: for commercial solutions, even Rosatom chooses more time-tested water-water solutions.

Finally, the ideal from the point of view of economics would be reactors not with steam, but with gas turbines – of the BN-GT type, but without sodium. The problem is that so far sodium-free liquid metal reactors for gas turbines with high efficiency do not exist even in the project. Yes, from China en/2021/09/17/ pervyj-v-mire-vysokotemperaturnyj-ga/" target="_blank" rel="nofollow">there is a small HTR-PM modular reactor with 105 megawatts of power. And yes, China is planning a series of two dozen such reactors.

But technologically there is little new in them. This is the reincarnation of the German gas-cooled reactor, which already worked in the last century. And his main problems are the same. It cools the tubes with nuclear fuel by driving helium through the core under high pressure. But even under enormous pressure, this light gas has a density much lower than that of liquid metal or even water. Therefore, reactors of this kind are very large – the hull of the Chinese HTR-PM is 25 meters high and weighs 700 tons. The 10 times more powerful VVER-1200 reactor weighs half as much. Naturally, the unit cost of HTR-PM is higher than that of water-water or liquid metal analogues.

The future hardly lies in this direction. It is more likely that they will be reactors with a very difficult to boil and chemically inert coolant – such as lead-bismuth. But they will have to work in reactors where the fuel tubes and walls will not be made of steel, as in today's Russian SVBR project, but of more heat–resistant materials - such as silicon carbide or something no less heat-resistant.

Nevertheless, one thing can be stated with great certainty. Small reactors have a great future – there are too many small cities on the planet for which gigawatt units, fashionable in the last decades, are excessively large.

Alexander Berezin