We are talking about the life support system of the International Space StationIn the near future, humanity will learn how to organize long-distance space expeditions, and a manned flight to Mars will no longer seem like a fantasy.

However, the development of distant planets requires the creation of a comfortable autonomous environment that allows you to do without replenishment from the outside for a long time. In Russia, a unique scientific institution, the joint-stock company "Research and Design Institute of Chemical Engineering" (JSC "NIIHIMMASH"), is engaged in the creation of life support systems for spacecraft on orders of S.P. Korolev Rocket and Space Corporation Energia.

Specialists of the Institute do not like to communicate with the press, but they made an exception for TASS.

From the mortar factory to the Research Institute

The Institute traces its history back to 1943 and was founded on the basis of a small factory engaged in mortar armament. The founding father of JSC NIIHIIMMASH is the famous Soviet academician Nikolai Antonovich Dollezhal, the creator of the first nuclear power plant in the history of mankind (the Obninsk Atom Mirny — 1 reactor). Soon the nuclear industry began to develop at a tremendous pace, and it was decided to create a separate independent Research and Design Institute of Power Engineering. JSC Niihimmash continued to engage in, as the scientists themselves say, "very tricky chemical processes."

In the mid-60s, when the USSR was already actively exploring outer space, scientists began to look for ways to increase the duration of a person's stay in space. The flight of the world's first cosmonaut Yuri Gagarin in 1961 lasted only 108 minutes from launch to landing. "Nikolay Mikhailovich Samsonov (Professor, Doctor of Technical Sciences, former Director General of the Institute — approx. TASS) was the only one who said that Niihimmash JSC would take up this case," says Alexander Sergeyevich Tsygankov, Director General of the Institute. Under the leadership of Nikolai Mikhailovich, a special experimental design bureau was formed (currently Department No. 10), which is engaged in the development and manufacture of space life support systems. In the Soviet years, it was impossible for a mere mortal to get into this unit — the activities of the department were classified.

In the 90s, like many other post-Soviet scientific institutions, Niihimmash was going through hard times. "Thank God, on the life path of the institute, people met, not without whose participation the organization remained afloat. One of them is the former chief designer — head of the department — Alexey Anatolyevich Kochetkov, who organized the experimental production of the department in the difficult 1990-2000 years for the country directly on the territory of the institute. A lot of the company's activities have disappeared, but space has remained," says Alexander Sergeevich.

Fighting for every gram

One of the main features that must be taken into account when developing space life support systems is the absence of gravity on a space object. "An ordinary container on Earth works without problems: water flows out of it under the influence of gravity. If a simple household container is shipped to the space station, it simply will not work — the liquid will not flow out of the container spontaneously, and if it can be extracted, it will turn into a drop due to surface tension forces," says Alexander Sergeevich.

|

| An analytical laboratory where water samples from systems operated on the ISS are checked. |

| Source: © Ekaterina Adamova/ TASS |

Another serious problem in the development of systems is associated with the lack of a full-fledged verification of the operability of equipment on the Ground. In the Soviet years, many products of JSC Niihimmash were tested with the help of flying laboratories. In conditions of short-term weightlessness due to the free fall of cargo planes, design solutions used in space equipment were tested. However, in recent decades, the practice of using flying laboratories has been lost.

A separate task is the delivery of equipment to astronauts on the ISS. In Russia, there are two types of cargo delivery into space: with the help of so-called "trucks", unmanned space transport vehicles of the Progress series, as well as manned Soyuz spacecraft. "Cargo delivery to the ISS on a transport cargo ship costs from 1 to 1.5 million rubles per kilogram of payload. Delivery by a manned ship is much more expensive," says the general director of the enterprise and reminds about the serious bonuses of the Soviet years for each gram saved during the development of the devices.

As a result, the specialists of JSC Niihimmash face a number of seemingly impossible mutually exclusive conditions. Firstly, space equipment should be as light as possible, but at the same time rigid and durable enough to ensure resistance to overloads during takeoff and launch into orbit. Secondly, it is extremely reliable — the delivery of spare parts to space is a very expensive pleasure. And thirdly, it is maintainable and simple, so that in case of an unexpected breakdown, astronauts can fix it. "Our specialists need to ensure all these requirements and confirm their fulfillment on tests," says Alexander Sergeevich.

"Scientists of JSC Niihimmash are constantly fighting for compactness, energy efficiency and weight reduction of equipment. Despite the fact that the small hydraulic circuit of the device can be graphically represented literally on an A4 sheet, this product can be the key and most responsible link in the system. Accordingly, such nuances are reflected, among other things, in the peculiarities of production," says Sergey Nikolaevich Rukavitsin, Chief Designer of JSC Niihimmash.

Thus, experts point to another important feature of the work of JSC Niihimmash: the institute's production is experimental, single. "Yes, we have products that are delivered on board from year to year with a certain frequency, but despite this fact, production remains experimental, and the laws of mass production are mostly unacceptable," says Sergey Nikolaevich. As an example, the interlocutor cites a part of the system on board the ISS, made of a 30-kilogram titanium billet. The finished part weighs about 500 g, all the rest of the material has been processed into chips. At first glance, it will seem that it is more cost-effective to make a part by casting or stamping, but in fact everything is different.

"The production of a stamp will cost many times more expensive than the production of a part by mechanical processing in the framework of pilot production," the specialist emphasizes.

Titanium and aluminum are the main metal materials used in the manufacture of life support systems for space. The list of materials approved for use has been developed and approved by the Institute of Biomedical Problems (IBMP) of the Russian Academy of Sciences. The use of other materials is strictly controlled by special technical services due to the need to ensure a safe atmosphere at the station. "On the ISS, people are constantly in a confined space, and no one knows how plastic will behave in a couple of months or a year, what substances it will begin to emit. Old Soviet materials are used not at all because we cannot come up with something new, but due to the fact that the materials used for many years do not emit anything that could harm human health," says Alexander Sergeevich.

Water and oxygen on board the ISS

The specialists of JSC NIIHIMMASH have created reliable regenerative life support systems that have been successfully used on the Salyut, Mir space stations, and currently on the ISS. The systems not only provide the possibility of a long stay of astronauts at the station, a number of the institute's latest experimental developments in the future are able to save hundreds of millions of rubles on ensuring the life of Russian cosmonauts in orbit.

To date, the record for the duration of continuous stay on board the International Space Station has been more than a year. The absolute world record for continuous stay on the ISS belongs to Russian cosmonaut Peter Dubrovu and astronaut Mark Vande Hai, who jointly spent 355 days in orbit for one continuous flight. Currently, the issue of providing astronauts with equipment, food, water and everything else on the ISS during the flight, although expensive, is quite solvable. Another thing is the future long—range space expeditions to the Moon and Mars, the success of which directly depends on the development of promising, fully autonomous space life support systems. The flight to the same Red Planet, depending on the trajectory, will take from 250 to 300 days.

At the moment, life support systems are being used on the space station, which make it possible to ensure partial closure of the cycle and return water and oxygen to circulation for breathing due to physico-chemical processes. Various versions of these systems have successfully operated at the Salyut and Mir stations, and now they are functioning on the ISS in a modernized form.

One of the most stable systems developed by JSC NIIHIMMASH is the water regeneration system from atmospheric moisture condensate (SRV-K2M), the first applications of which were as part of the Salyut-4 orbital space station. The system provides more than 50% return of water to the consumption cycle. Deservedly, this system is considered the best in the world in terms of the unit cost of equipment weight per 1 kg of water received and the average daily cost of electricity per astronaut.

The most important development of the Institute is the Electron—VM system for electrolysis of oxygen from water. In 2022, a backup system was added to it, installed on board the multipurpose laboratory module Nauka, which is part of the Russian segment of the ISS. Both systems are completely interchangeable, which ensures an uninterrupted supply of oxygen to the crew in case one of the systems needs maintenance or it fails.

|

| Electron-VM. |

| Source: © Ekaterina Adamova/ TASS |

The Institute admits that it is possible to use the Electron-VM system to complete the Russian Orbital Service Station (ROS). "At the moment, the final oxygen supply scheme has not been selected, which oxygen generation system will be installed on the ROS. But there is certainly a possibility of ordering the Electron-VM system, since the product has proven itself from the best side in terms of reliability, safety and energy efficiency," the company's specialists note.

The Electron-VM system, which is installed on board the ISS, has already worked for 12 years with a stated warranty period of one year in length. The capabilities of the system are designed to simultaneously provide oxygen to three or four people. The system is capable of producing from 25 to 160 liters of oxygen per hour and additionally from 50 to 320 liters of hydrogen per hour.

Savings of hundreds of millions of rubles

Currently, the specialists of JSC Niihimmash are working on a promising direction — a system for processing carbon dioxide (SPDU), or, more simply, carbon dioxide. "A person on board the space station, as well as on Earth, constantly inhales oxygen, and exhales CO2. Carbon dioxide accumulates in a closed sealed object. The tasks of the SPDU include the conversion of CO2 into water. Now the atmosphere of the station is being cleaned by the "Air" system, and carbon dioxide is thrown overboard. The main purpose of creating a SPDU is to get valuable water on board, ensuring a large closed cycle," explains Sergey Nikolaevich.

The system consists of two main blocks. One unit collects and concentrates CO2, the second processes it into water, thus reducing the amount of supplies from Earth. "The water obtained with the help of the system can be further directed to drinking through the water regeneration system from atmospheric moisture condensate (SRV-K2M). It is also possible to use it as flushing water in the system of receiving and preserving urine (SPK-UM) or source water entering the electrolysis system "Electron-VM" for oxygen production. Thus, we are trying to ensure the isolation of our systems," the chief designer of the enterprise clarifies.

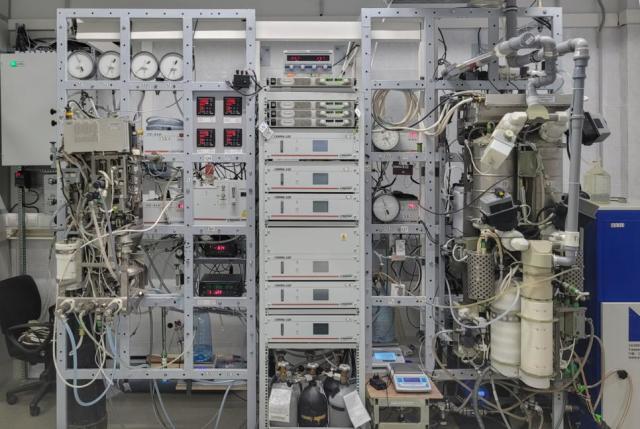

|

| Carbon dioxide Processing System (CPS). |

| Source: © Ekaterina Adamova/ TASS |

It is planned that after commissioning, the system will be able to provide 60 ml of water per hour. "A total of 525 liters of water per year. If we calculate, based on the minimum cost of 1.2 million rubles for the delivery of a kilogram of payload on board, we get about 630 million rubles of savings per year. A comparative analysis of financial investments in the development and manufacture of the system and the expected economic effect confirms the high value of this work," says Alexander Sergeevich.

The development of the SPDU is carried out by JSC Niihimmash by order of one of the leading rocket and space enterprises of Russia - Rocket and Space Corporation (RSC) Energia. Now the stage of manufacturing a prototype and conducting tests is coming to the final. "When the stage is completed, we will be able to say that the working design documentation is ready for the production of a flight sample of the system," Sergey Nikolaevich notes.

The second promising direction, on which the specialists of JSC Niihimmash are currently working, is a system for the regeneration of water from urine (SRV-U-RS). The system is operated on board the ISS as part of a scientific experiment, being not a standard system, but scientific equipment. Scientists and engineers of the enterprise are making every effort and experience to ensure that all available resources are used as efficiently as possible on the space station — even such specific ones as human urine.

"The preservative, being a strong oxidizer, ensures the preservation of urine, does not decompose and ensures the absence of bacterial reproduction. Canned urine can be stored in this state for about two years so that water can be extracted from it. It is irrational to throw liquid in space, realizing that it can be the raw material for our system," the scientist notes.

The resulting water from urine, after all physical and chemical processes, turns out to be very clean and theoretically absolutely drinkable, but is directed to technical needs.

The cosmic shower will become a reality

Cosmonauts and astronauts spend many months in orbit. It would be reasonable to assume that astronauts somehow have to take a shower on board the station. But no, even decades later, the hygiene product in space has remained the same — wet wipes.

The shower was on the Mir space station, but they decided to abandon the idea of using it on the ISS because of the inconvenience of the system. After washing, it was difficult for the astronauts to collect water around the station, which turned into flying balls in zero gravity. Now the specialists of JSC Niihimmash are trying to solve the most difficult task of creating the most convenient and ergonomic washing system in space, and also carry out design work on the nodes of the sanitary and hygienic water regeneration system.

The use of the usual shower cabin design on the ISS is impossible — in zero gravity conditions, water will not flow down. Experts have been working on a variant of the device, where transport air will come out together with water droplets, "pushing" water down to the feet to the droplet collector. It was assumed that a vacuum cleaner would suck the water from below. "One small "but": the high speed of air movement leads to a temperature drop — at the head — 60-70 degrees, and in the area of the legs the temperature will be slightly lower, and the person will freeze. The practice of using a shower by astronauts at the Mir station also led to the fact that after washing they had to collect water balls with towels, and then wring them out. Small subtleties that are difficult to take into account on Earth can put sticks in the wheels of even the most wonderful scientific and design ideas in space," Alexander Sergeevich notes.

But there are also requirements for the energy efficiency of systems and components that engineers must take into account. All space systems consume ten times less energy than a conventional electric kettle. Designers and scientists are literally squeezed into this framework. There is a large shortage of electricity on the ISS, which is provided by solar panels. They issued a requirement for equipment power of 500 watts — at first glance very little, but the system should work with motors, pumps, sensors, control panels. If suddenly the development did not meet, no one will provide an additional generator on board, respectively, serious problems will arise. "Part of the time the station stays on the sunny side — solar panels collect energy, and part of the time in the shade, where there is no possibility of charging them. But oxygen generation must be provided constantly, the toilet must work continuously to ensure the comfort of staying at the station. Such subtleties play a very important role in the development of life support systems," the general director of the enterprise emphasizes.

|

| A chamber with a carbon dioxide recycling system simulating the atmosphere on board the ISS. |

| Source: Chamber with Carbon Dioxide Recycling System |

Nevertheless, the specialists of JSC Niihimmash already have developments that make it possible to bypass the features of weightlessness, and are working on a device that in the future should ensure the availability of hygienic procedures for astronauts. The details and ideas of the design and applied physical processes are not yet advertised by scientists. "We already have the concept of a device for washing in zero gravity. Details on the implementation of the idea at this stage have not yet been demonstrated to third parties," Alexander Sergeevich said.

Washing clothes in the absence of gravity is also not easy. Now used clothes are disposed of after use. "Astronauts certainly need a washing machine. According to preliminary estimates, a total of one cargo ship is recruited per year in terms of the number of clothes. Recycling clothes is money thrown away. This task has not yet been solved either by the Russians or by representatives of other countries participating in the ISS project," the specialists of JSC Niihimmash emphasize.

Scientists of JSC Niihimmash worked in several directions of creating a space washing machine with a different principle of operation. However, it is extremely difficult to carry out full-fledged research and development work in this area without sufficient funding and involvement of the customer in the person of RSC Energia, according to the management of the institute.

To the question whether it is possible to achieve full autonomy of the station or the ship during long-distance space flights, experts answer unequivocally: it is not yet possible. "Our team can implement various physical and chemical processes, but then it will not be the ISS, but thousands of hectares of a chemical factory that will chase some last element of the periodic system. We strive for 100% isolation of the space station, like planet Earth, which no one supplies from the outside. But with all this, we understand that there is always a certain technological limit that will not allow us to reach these 100%," Alexander Sergeevich summarizes.

The scope of application of space life support systems in reality can be quite extensive: from orbital stations and interplanetary ships to submarines and bomb shelters. And in the light of the complication of the global socio-political situation, this topic is becoming more and more relevant.

"The old-timers will leave, but there is no one to replace them"

In the Soviet years, the Moscow JSC Niihimmash was the main institution in the chemical engineering industry, 15 more branches of the institute worked throughout the country. "Huge institutes with factories are a real corporation. Previously, more than 3 thousand people worked only on the territory of Moscow, and now there are about 300 specialists left. Of course, we try to make the number of specialists grow from year to year, we are not going to stop there," says Alexander Sergeevich.

"Personnel remains one of the main problems of the enterprise. Or rather, their absence. In the Soviet years, specialists of a wide profile for the enterprise were trained on the basis of the MIHM — Moscow Institute of Chemical Engineering. Then only the department remained of the institute, and eventually it also disappeared. We are forced to look for bright heads who have not gone into commerce or banks. There are very few people who currently seek to engage in science," says Alexander Sergeevich. The luminaries of science, leading specialists of JSC NIIHIMMASH, who stood at the origins of the development of life support systems, such as L.S. Bobe, N.S. Farafonov, Yu.P. Bottle, are 80-90 years old. They have devoted their entire lives to chemical engineering and are still in service.

"Now we need a fuse, initiative, knowledge. We are forced to take risks and put young specialists in quite serious positions — head of the laboratory, deputy head of the department. These are people under 40 years old, although they would need to grow up a little more. But the company is forced to take such measures, otherwise we simply will not cope with the problem of continuity of generations. The old—timers will leave, and there is no one to replace them," the Director General of the Institute summarizes.

Ekaterina Adamova