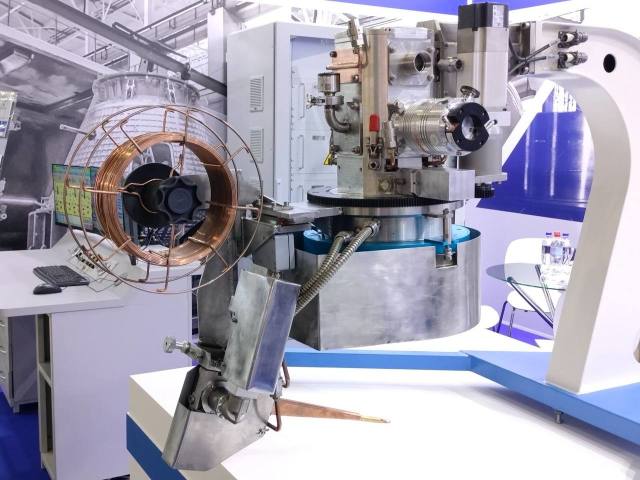

Rostec State Corporation has presented a vacuum electron beam 3D printer with an all-angle robot manipulator. The device allows you to "grow" heavy-duty parts of complex construction made of titanium and steel for aerospace engineering. A prototype of the product can be seen in Moscow at the international exhibition Weldex-2022. The vacuum 3D printer is a joint development of specialists from Perm National Research Polytechnic University and the Progress Research Institute of Technology, managed by RT-Capital of Rostec.

Electron beam fusion technology allows you to create heavy-duty parts using special wire made of aluminum alloys, titanium and heat-resistant steel. The all-angle robot manipulator – the main feature of the 3D printer - is able to "grow" products of complex design and various shapes in vacuum conditions. Vacuum in this case is an ideal medium for obtaining alloys with increased strength – a characteristic especially important for products of the aviation and space industries.

"The use of electron beam fusion technology allows to multiply the strength index of the part. For example, for stainless steel products, it increases by 16%. In addition, with the help of a 3D printer, you can get a part of any design up to 2 mm in size. We plan to complete testing of the prototype device by the end of this year," said Alexander Nazarov, Deputy General Director of Rostec State Corporation.

You can see an electron beam 3D printer in action at the international exhibition of welding materials, equipment and technologies Weldex, which takes place from October 11 to 14 at the Crocus Expo exhibition center. The prototype is presented in the Progress THREAD pavilion.