Icing of an aircraft is one of the most important problems in the operation of an aircraft, directly affecting flight safety. Research on this topic is conducted at the Central Aerohydrodynamic Institute named after Professor N.E. Zhukovsky (part of the Research Center "Institute named after N.E. Zhukovsky").

Currently, specialists are working on a project within the framework of the competition of the Russian Foundation for Basic Research, the practical result of which will be models of icing of the aerodynamic surfaces of the aircraft. TSAGI scientists use additive technologies to make ice simulators.

Specialists of the Institute are developing special pads simulating ice on the surfaces of an aerodynamic model of an aircraft in stereolithography technology. As the main structural material, a liquid photopolymer is used, which hardens under the influence of ultraviolet irradiation.

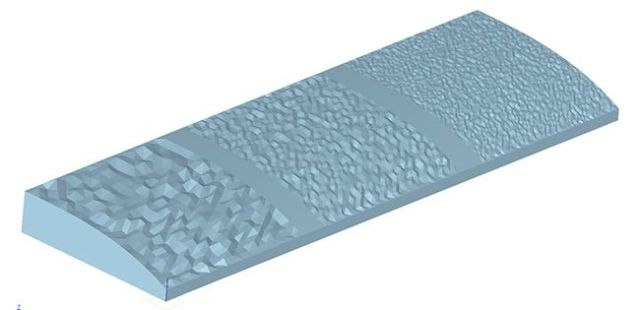

|

| Mathematical model of the test part. |

| Source: TSAGI |

Since the surface of the ice has a rather complex shape, scientists use both calculated and experimental data obtained in the TSAGI air-cooling pipe to develop simulators. In turn, the results of the project will make it possible to further refine and improve the digital mathematical models of calculated icing cases used by specialists.

"The pads allow us to study the effect of ice on the aerodynamic characteristics of the aircraft. Icing simulators are applied to those surfaces of the aircraft model that are most vulnerable to this undesirable phenomenon — for example, the leading edge of the wing. Further, the effect of ice on stability and controllability parameters is experimentally determined. As a result, we can replenish the bank of aerodynamic data on the effect of icing, and in the future — give relevant recommendations to pilots on how to avoid its negative consequences in flight," explained Prokopy Nikolaev, head of the department of the scientific and technical center of the scientific and production complex of the FAU "TsAGI".

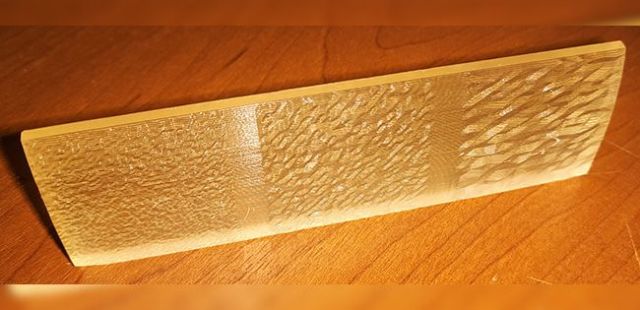

|

| A manufactured part with an imitation of the surface of ice. |

| Source: TSAGI |

Stereolithography has proven its effectiveness for solving the tasks that TsAGI traditionally deals with, and is successfully used at the Institute. Its advantages are the speed and cost-effectiveness of manufacturing. Another factor "for" the use of technology is accuracy: about 20 microns (0.02 mm).

Among other examples of the application of stereolithography at the Center for Aviation Science is the creation of models for hydrodynamic pipes. The features of the technology of manufacturing parts from photopolymer allow us to produce a complex internal structure of the model with a network of highways for the output of dyes. Thanks to this, it is possible to quickly prepare experiments to study the flow pattern using coloring liquids. Another important property of stereolithography is the ability to produce thin-walled lightweight parts from photopolymer and use them in the production of dynamically similar aircraft models.

MOSCOW, TSAGI Press Service