The Center for Additive Technologies of Rostec State Corporation and the Moscow Center for Laser Technologies (MCLT), a scientific and engineering center at Bauman Moscow State Technical University, have signed a cooperation agreement. The document aimed at creating equipment for industrial 3D printing was signed by Vladislav Kochkurov, Director General of TSAT, and Alexander Grigoryants, Director General of MCLT.

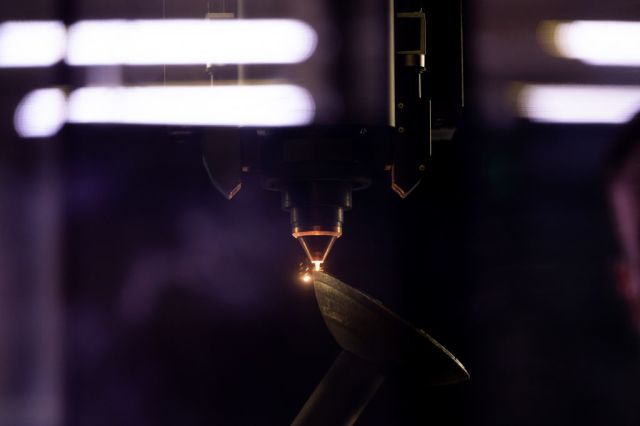

Within the framework of the project, the Center for Additive Technologies will test and pilot operation of a 3D printing plant based on selective laser melting technology developed by specialists of MCLT. Prototypes of products manufactured on new domestic equipment will be tested for compliance with the technical characteristics required for aviation products. The next step will be the start of serial production of 3D printing equipment.

"The main consumer of the Center for Additive Technologies' products is the aircraft industry. The creation of promising aircraft, such as Superjet 100 or MS-21 aircraft with domestic PD-8 and PD-14 engines, is unthinkable without 3D printing technologies. Our task is to provide the appropriate capabilities, to offer aircraft manufacturers the best production solutions. The joint work with Baumanka is aimed at creating a new generation of domestic equipment for these purposes," said Vladislav Kochkurov, General Director of the TSAT.

The prototype 3D printer is designed for growing products up to 250x250x300 mm in size from metal powder materials: aluminum, bronze, titanium alloys and stainless steel.