The enterprises of the aircraft manufacturing sector of the defense industrial complex of China have established strong relations with the Pakistan Air Force, which was achieved, among other things, thanks to successes in the development of aircraft engines.

Today, China's defense industry regularly supplies Pakistan with light single-engine generation 3+ fighters under the designation JF-17 "Thunder" in several modifications. To date, the Pakistani military has received 50 aircraft in the Block I modification and 62 fighters in the Block II version, which differ in the presence of an in-air refueling system, the structure of the onboard electronics complex and other nuances.

In the manufacture of the airframes of the second modification, Chinese specialists used more composite materials, which allowed to reduce the weight of the fuselage and positively affected the thrust-to-weight ratio of the fighter, for which this is a key indicator. Currently, the assembly of fighters of the Block III modification is underway. In their design, the proportion of composite (carbon fiber) materials has been maximized, a new radar has been used, as well as some new components and materials. In addition, at the end of 2019 The Pakistan Air Force has received the first batch of two-seat JF-17B fighters, which are probably equipped with WS-19 engines.

Two-seat fighter JF-17B of the Pakistan Air Force

Production of aircraft engines – search for options

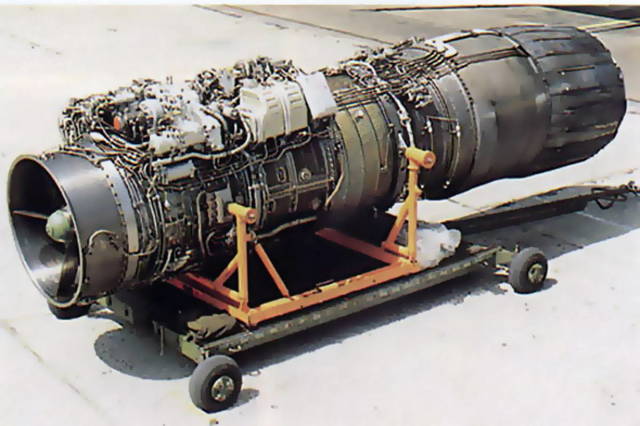

It should be noted that the combat aircraft in question are equipped with either Russian RD-93 aircraft engines (RD-33 modification) or Chinese WS-13E (R&D under the code "Taishan-21"). The latter are exact copies of power plants supplied from the Russian Federation. Although Chinese specialists used cheaper alloys in the manufacture of compressor blades, they compensated for this by applying high-temperature ceramic compounds that allow the engine to function normally at a temperature of 1650K. Thanks to the "ceramic tricks", Chinese specialists managed to extend the service life of the motor up to 2200 hours, while the first repair can be done after 810 hours.

Russian RD-93 aircraft engine

The main part of the work was carried out by employees of the sixth shop of the 126th Mechanical Plant, located in Anshun, Guizhou province. Previously, this company specialized in the production of aircraft engines of the WP series, but after the successful development of the WS-13 production, this plant performed a complex of works on AI-25 series engines, which were assigned the designation WS-11 in China.

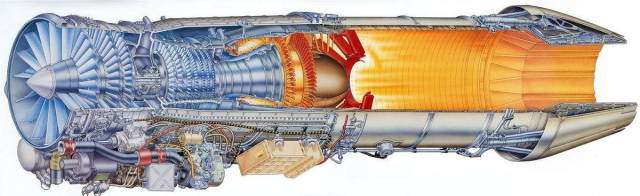

According to Chinese sources, even at the design stage of the first variant of a promising fighter for the Pakistan Air Force (R&D under the code "Super-7"), Chinese designers expected to equip this fighter with an American F-404-GE-402 engine, which was mass-produced by General Electric for early models of the F/A-18 fighter.

It is known that the license for the production of this engine was acquired by Volvo, which produces the specified engine under the designation RM12 for JAS-39 Gripen fighters from the Swedish company SAAB. Chinese experts note that this European-made aircraft is not inferior in its tactical and technical characteristics to such a common American-made fighter as the F-16.

The RM12 aircraft engine from the Volvo company

Based on the F-404-GE-402 aircraft engine, a deformed version was created under the designation F-412, as well as F-404-GE-F1D2, which were installed on the first inconspicuous fighter-bombers of the US Air Force F-117A Nighthawk.

Chinese designers and representatives of the PLA Air Force highly appreciated the reliability and ease of maintenance of the F-404-GE-402, which is more compact in linear dimensions than the Russian RD-93, and also somewhat lighter. However, to install such an engine inside the fighter's hull, it would be necessary to redesign the locations of the auxiliary power plant, generator and fuel pump. The main advantage of the American engine is a significant resource. According to this indicator, the F-404-GE-402 exceeds the Russian RD-93 three times.

It is reliably known that Chinese engine builders focused specifically on the F-404 GE-402 because at that time in the USA only Pratt & Whitney produced a similar engine in the F-100 series, but its reliability remained at a low level. Observers of Chinese specialized military-technical publications note that in the 80s of the last century, the enterprises of the defense industry of the People's Republic of China did not have the technical and personnel capabilities to copy the F-404-GE-402.

According to Chinese analysts, even the leading engine-building enterprises of China were not able to adequately copy the components of such a powerful and compact turbojet aircraft engine. Such a state of affairs did not suit the leadership of the defense industry, since China would become dependent on the supply of engines from the United States. It is obvious that back in the 80s of the last century, Chinese industrialists and the military were aware of the danger of foreign supplies.

Appeal to Russian technologies

In fairness, we note that Chinese experts also counted on the purchase of such American-made power plants as PW1120 and PW-1126 from Pratt & Whitney. The first engine was developed by American designers as a replacement for the problematic engines of the F-100 series for next-generation fighters. However, it has not been distributed and is currently used only on Kfir fighters – the Israeli version of the French Mirage-5. The second engine was developed for advanced combat training aircraft. However, since after the events on Tiananmen Square in 1989, US-Chinese relations in the field of military technology were curtailed by Washington's decision, official Beijing lost access to any military technology. In fact, American politicians have seriously slowed down the development of the defense industry of the People's Republic of China and, as a result, combat aviation.

European aircraft engine EJ-200

In addition to these American developments, Chinese specialists counted on the purchase of turbojet aircraft engines of European production, namely: RB199 from the British company Rolls-Royce and EJ-200 – a joint development of Rolls-Royce, MTU (Germany) and FaltAviv (Italy). The inability to purchase these engines is due to the continuing embargo on the supply of military and dual-use technologies and equipment, which was introduced after the events of 1989.

In such a situation, Chinese engine builders were forced to turn to the Russian side for RD-93 engines. The Chinese side realized that the purchase of one batch of these engines would not allow the planned supply of JF-17 for the Pakistan Air Force, since it was necessary to reserve part of the engines for replacement and repair. In addition, India may influence Moscow, and the Russian authorities will make concessions to a strategic partner. It was the understanding of all these points that became the "driver" of the development work, as a result of which Chinese specialists created the WS-13 turbojet aircraft engine.

Pakistan Air Force JF-17 BlockII Fighter

In the process of experimental military operation, some problems were revealed, which were reflected in the complaints from the Pakistan Air Force. It took Chinese designers several years to rectify the situation and by now the Pakistani military has agreed to purchase aircraft with the WS-13E or even with its modified version under the designation WS-19.

Summing up the above, it seems possible to note that Chinese engine builders in the process of creating a power plant for the JF-17 have gone through a difficult path of creating a compact turbojet aircraft engine of medium power. It was thanks to the efforts and time spent that Chinese specialists managed to create a new engine that will be useful for the new inconspicuous light fighter "Jian-31".

Based on the materials of Chinese specialized military-technical publications