The machine tool industry is the most important, its condition largely determines the level of development of Russian industry and the economy as a whole. Now, when the import of industrial equipment is limited, the development of its own machine tool industry is among the most important tasks for the country. The topic of import substitution in this industry is not new for Russia. The most obvious example in the history of our country is the industrialization of the 1930s, when in one five-year period the number of machines of domestic production increased significantly.

The decline of this industry in the 1990s, the lack of specialists and developments today - everything cannot be overcome overnight. But work in this direction is underway, and quite confidently. Rostec plans to make a real breakthrough by creating a holding company specializing in the development and production of heavy processing equipment and tools. By 2030, the company intends to occupy half of the Russian market of industrial machine tools.

The rise and fall of the domestic machine tool industry

At the beginning of the last century, the First World War and the Civil War almost completely undermined the country's economy. The existing machine park could barely meet the needs of the enterprises being restored. However, soon an ambitious task was set before the country – in 1928 a five-year plan for the development of the national economy was adopted. According to the results of the first five-year plan, the country should turn from an agrarian one into an industrial one, capable of producing the necessary equipment on its own.

For five years, the production of machine-tool products in the country has grown at an unprecedented pace. These years are often called the time of the birth of the Soviet machine tool industry. The official date of the industry's emergence is May 29, 1929, when Stankotrest was formed. By 1932, eight factories had launched the production of lathes, grinding and milling machines. By the beginning of the Great Patriotic War, several dozen such enterprises were already operating in the country. During the harsh war years, about 80 thousand metal-cutting machines were produced alone.

In the post–war years, the machine tool industry had two main goals - to increase the volume of output and improve its technical characteristics. New machine-tool factories have started operating in various regions of the country: Minsk, Ryazan, Kolomna and others.

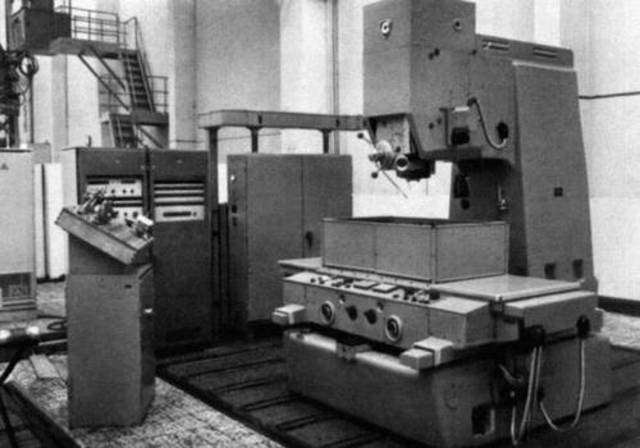

Soviet coordinate boring machine of particularly high precision with CNC

There is an opinion that the USSR could not compete in the production of automated machines. The production of CNC machines in the country was established in the 1970s, about several dozen models. In 1991, more than half of all the necessary equipment for the production of such machines was manufactured in the country. At the time of the collapse of the USSR, tens of thousands of Soviet machines were working abroad: in Germany, Switzerland, France, Japan. In 1991, about 50 pieces of Soviet equipment were presented at the Paris Machine Tool Exhibition.

In the early 1990s, the machine tool industry in Russia began to lose its former positions. The output of metal-cutting machines has decreased significantly, and CNC machines in general by dozens of times. In 2009, the production of machine tools reached the lowest level in the history of the country. By this time, many machine-tool factories were closed, the remaining ones worked very poorly.

Return to your "CAMP"

The first steps to "reanimate" the industry were taken already in the "zero". In 2009, the state structure "RT Mechanical Engineering" was established. Four years later, on its basis, Rostec created the system integrator of the Russian machine-tool industry "Stankoprom", which united research institutes, machine-tool enterprises, tool factories, commercial and engineering enterprises.

In 2012, private investors formed the holding "STAN" on the basis of the Sterlitamak machine-tool plant, which included several other enterprises of the industry. Today the structure of the holding includes: NPO "Stankostroenie", "Stankotekh", Ryazan machine-tool factory, Ivanovo machine-tool plant, "Grinding machines", "Donpressmash". Modern equipment is produced at production sites. According to representatives of the company, ten model ranges of "STAN" cover similar products of 25 foreign brands.

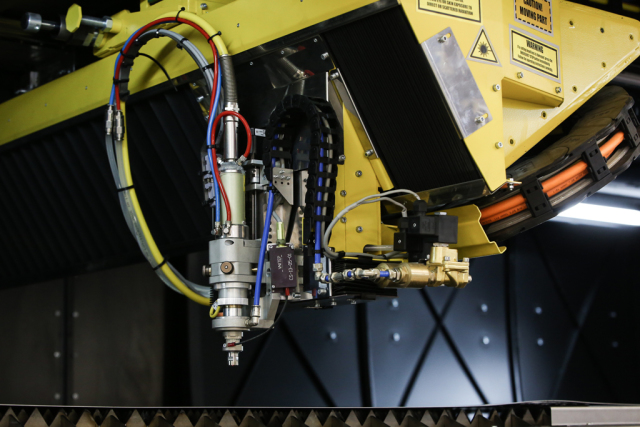

Photo: Igor Generalov

Rostec State Corporation in 2019 decided to support STAN in a difficult situation, and offered its competencies in the field of crisis management aimed at stabilizing the company's financial situation, developing new competencies, and increasing export opportunities. In 2021, STAN together with RT-Capital of Rostec State Corporation launched the production of a new line of high-speed high-precision portal centers. This equipment is unique for the Russian market, its capabilities have no analogues among domestic developments. And the possibilities of the novelty are really impressive – in production, such a center can replace three types of universal machines, perform more than eight operations per session, halve the manufacturing time of the part.

The products of the Rostec State Corporation's machine-tool assets can be viewed at the annual Metalloobrabotka exhibition, which has been held since 1984 and is the largest domestic project in the field of machine-tool construction. Last year at this exhibition, in addition to STAN, 577 more machine-tool enterprises presented their achievements, including Stankoprom and the Kalashnikov Concern. The latter, for example, is the only official manufacturer of IZH 250ITVM machines in Russia. Machines of this series are "workhorses" at instrument–making and machine-building enterprises.

Rostec – behind the machine

In 2020, the Government of the country adopted the "Strategy for the development of the machine tool industry for the period up to 2035", in which it was noted that the current volume of production of metalworking equipment covers only 17% of domestic demand. In fairness, it can be noted that in 2016 this figure was only 8%. The contribution of the machine tool industry to the gross domestic product is 0.02%, which is several times lower than the indicators of the main leading countries in the production of machine tools: China (0.15%), Japan (0.23%), Germany (0.32%).

At the same time, the demand of domestic enterprises for high-tech equipment is growing, especially taking into account the transition to a new technological way and digitalization of production. Now, when the import of foreign industrial equipment is limited, the development of own manufacturers of machine-tool products is included in the list of key tasks of the country.

Photo: STAN company

In the "Strategy for the development of the machine tool industry for the period up to 2035", the production of machine tool products is planned to grow at an average rate of 5.7% per year, to the level of 79.5 billion rubles by 2035. At the same time, the increase in the localization level of Russian products in the industry should grow to 70% due to the development of domestic production of key high-tech components.

Rostec's new initiative, the creation of a holding company specializing in the development and production of heavy processing equipment and tools for industry, will help put these plans into practice. The new holding will combine Rostec's existing machine-tool assets: Stankoprom and its subsidiaries, Progress Threads, and some other industry manufacturers. A unified structure will help to optimize production processes, focus on the development of new technologies in machine tool construction. By 2030, the united machine tool company intends to occupy up to half of the Russian industrial equipment market.