Masten Space Systems company presented the results of work on the project for the rapid creation of landing sites on the Moon using the exhaust of a rocket engine and aluminum oxide particles. Specialists have developed a two-level system for introducing particles into the engine nozzle and experimentally confirmed the viability of the idea in practice using a bench engine, it is reported on the company's website.

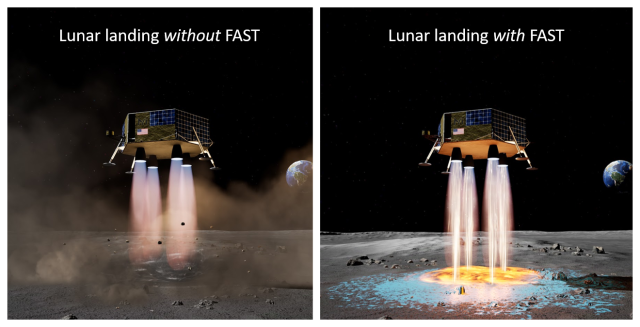

The FAST (in-Flight Alumina Spray Technique) project was proposed by Masten Space Systems last year as part of the next NIAC (NASA Innovative Advanced Concepts) competition and received funding for the first stage of work. It is aimed at facilitating the landing of vehicles on the surface of the Moon and reducing the lifting up of dust and stones by engine exhausts by creating an inexpensive platform under the vehicle right during landing. For this purpose, aluminum-based particles are introduced into the engine nozzle, which will melt and be sent to the regolith, forming a solid surface with it.

Image Source: Masten Space Systems

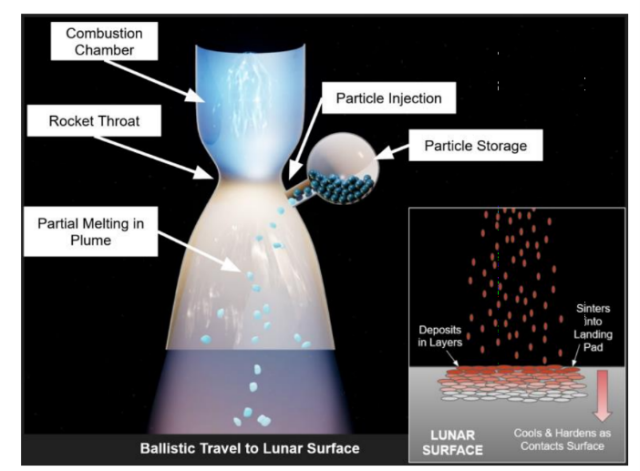

At the end of September this year, a team from Masten Space Systems with the support of Honeybee Robotics, Texas A&M University and the University of Central Florida presented the results of the work at the first stage of funding to move on to the next. Based on simulations and calculations, a two-level system for the introduction of aluminum oxide particles was developed: first, particles of 0.5 millimeters in size are injected into the nozzle, which collide with the lunar surface at a speed of about 1500 meters per second, creating an initial base layer 1 millimeter thick. Then, when the device approaches the surface, particles with a size of 0.024 millimeters are introduced into the nozzle, which increase the thickness of the pad. If you start injecting particles into the nozzle 30 meters from the surface of the Moon, then in 10 seconds you can create a platform with a diameter of 6 meters, which will cool down in 2.5 seconds.

Schematic diagram of the project.

Image Source: Masten Space Systems

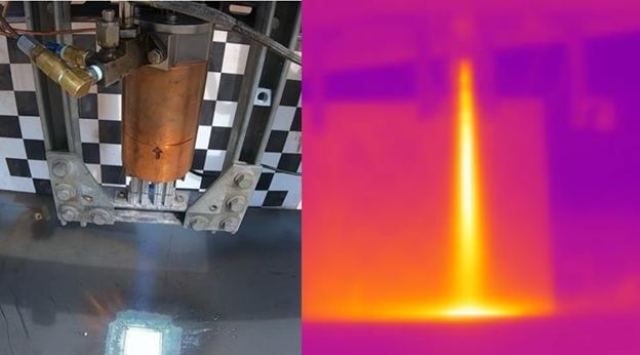

Experiments conducted with a bench rocket engine have shown that such a small-sized platform can indeed be created by introducing aluminum oxide particles into the nozzle. Calculations show that about 186 kilograms of working substance will be spent on a six-meter platform. If the project is re-approved by NASA, the research will continue.

Image Source: Masten Space Systems

Earlier we talked about how NASA approved the continuation of work on the lunar radio telescope, also being created as part of the NIAC program.

Alexander Voityuk