Engineers from the Massachusetts Institute of Technology, the California Institute of Technology and the Zurich Higher Technical School have demonstrated that materials created from nanoscale structures thinner than a human hair do not allow microparticles flying at supersonic speed to break through them. Such structures can become the basis for effective armor, protective coatings and explosion-proof shields for sensitive electronics, for example, in the defense and aerospace industries. The results of the study are presented in an article published in the journal Nature Materials.

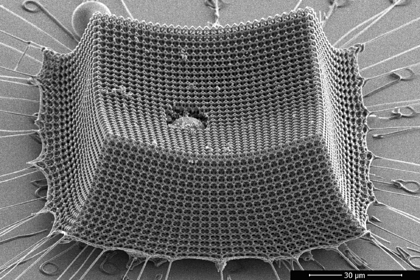

Specialists have created a three-dimensional carbon material with a nanostructure using two-photon lithography, when a laser beam moves through a liquid photosensitive resin, leaving behind hardened microscopic structures. A repeating configuration in the form of a fourteen-sided rectangle was chosen as a regular structure. A similar structure is characteristic of foam Ware-Phelan, which is used in the basis of energy-saving materials and in photonics. After annealing, the structure was placed in a high-temperature vacuum furnace to produce an ultralight carbon material.

To test the stability of the structure to extreme deformation, the team conducted experiments on microparticle impacts at the Massachusetts Institute of Technology. The laser was directed through a slide coated with a thin film of gold, which itself is covered with a layer of silicon oxide microparticles with a diameter of 14 microns. Passing through the glass, the laser generates tiny plasma explosions in the gold layer and thus pushes the silicon particles in the direction of the laser. The particle velocity can reach 40-1100 meters per second.

It turned out that the material dissipates the impact energy with an efficiency superior to traditional impact-resistant materials such as steel, aluminum, polymethylmethacrylate and Kevlar. Ultra-high-speed imaging and confocal microscopy have shown that the strength is provided by such mechanisms as the formation of compact seals (compact cratering) instead of excavating the material and the capture of microparticles formed from the impact. In other words, the microparticles were embedded in the material, and did not break through it.

A material with a nanoarchitecture consists of ordered structures of a nanometer scale, which, depending on how they are arranged, give the necessary properties. Scientists have proved that it is possible to predict how much damage will be caused to a material depending on the particle velocity and the density of the material itself using the pi theorem, similar to the fall of a meteorite on a planet.

Alexander Enikeev