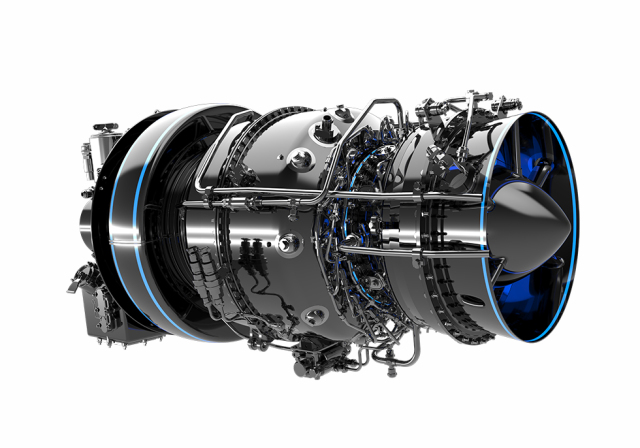

For the first time in Russian history, the United Engine Corporation Rostec designed the VK-1600V helicopter engine only using 3D modeling. All design documentation of the power plant demonstrator created at UEC-Klimov has been released in electronic form.

The use of 3D design has a number of significant advantages: it is easy to read, the use of models with annotations as design documentation and full accounting of all adjacent nodes.

"The VK-1600V is the first engine in Russian history that was designed without any drawings on paper at all. All work is carried out in electronic form, which allows you to always have the necessary contextual information in front of your eyes. Working with 3D models allows you to design the engine directly "inside" the helicopter, control the docking of objects both in the power plant itself and in the engine nacelle, "said Anton Kolosov, Acting Deputy Director of the program — acting Deputy Chief Designer of the VK-1600 of UEC-Klimov JSC.

When creating the VK-1600V demonstrator, up to 70% of the casting will be replaced with parts created using 3D printing. Elements, including the "hot" part of the power plant, will be manufactured using additive technologies.

Earlier it was reported that it is planned to present the VK-1600V demonstrator engine in the third quarter of this year. The assembled demonstrator will go to the first tests, where its main characteristics stated in the terms of reference should be confirmed. The type certificate is planned to be obtained in 2023, and in 2024 to launch mass production.

The new engine is designed for installation on Ka-62 helicopters, multi-purpose and special helicopters with a take-off weight of 5-8 tons. The power of the VK-1600V in take-off mode is 1400 hp. Together with the engine, it will work