NUST MISIS scientists in collaboration with Russian and foreign colleagues were able to improve the technology of obtaining medical alloys with shape memory. The new technique will improve the reliability of existing surgical devices and develop a number of new ones. The results of the study are published in the journal JOM.

Shape memory alloys (SPF) are materials that can recover their shape after severe deformations. The most widely used intermetallic SPFS based on Ti-Ni (titanium-nickel) are used in implants and "smart" medical devices with high reliability requirements - such as self-extracting surgical braces or vascular stents for cardiac surgery.

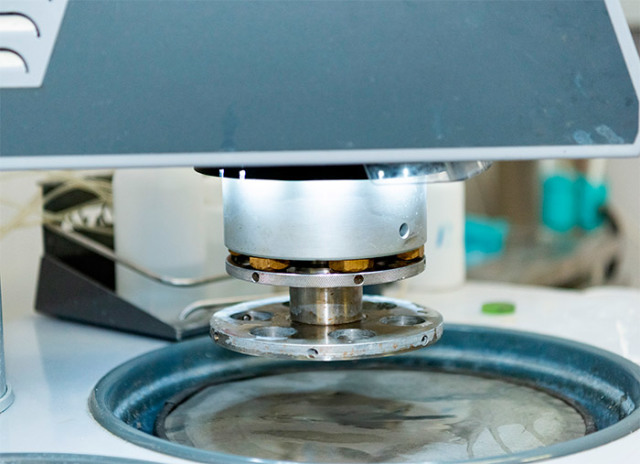

The maximum indicators of reversible deformation of the Ti-Ni alloy can be obtained by forming an ultra-fine-grained structure by thermomechanical processing at a temperature not exceeding 600°C. However, modern technologies for the production of titanium nickelide, as reported by scientists, involve melting and processing at temperatures from 800 to 900°C, which does not allow obtaining massive SPF blanks with an ultra-fine-grained structure.

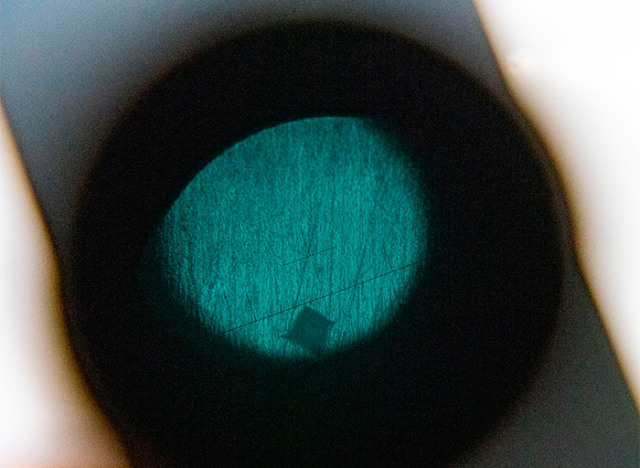

For the first time, NUST MISIS specialists have found the parameters of thermomechanical processing of titanium nickelide, which will make it possible to obtain massive products from SPF not only with the necessary nanostructure, but also with increased functional properties.

The use of nanostructured titanium nickelide according to the new technology, as explained by the scientists, will significantly reduce the metal consumption and increase the reliability of devices based on the shape memory effect.

In the course of the study, NUST MISIS scientists obtained strain diagrams for the first time and studied the formation of the SPF structure at temperatures below 600°C, which are the most promising for the formation of nanostructures. According to the scientists, the analysis of the obtained data also allowed us to determine the temperature ranges of the dynamic processes of return, polygonization and recrystallization of SPF.

The study was attended by employees of the Baikov Institute of Metallurgy and Materials Science of the Russian Academy of Sciences and the Technical University "Freiberg Mining Academy" (TUBAF, Germany). The research team will continue to develop recommendations for thermomechanical treatment of Ti-Ni SPF in industrial conditions.

The developers predict that the Ti-Ni alloy with an ultra-fine-grained structure and improved functional properties will create a new generation of medical devices based on the shape memory effect.

Information and photos provided by the NUST MISIS press service"