French shipbuilders are actively developing advanced technologies. Yesterday, January 13, the press service of the company Naval Group announced the completion of tests of the first screw made on a 3D printer.

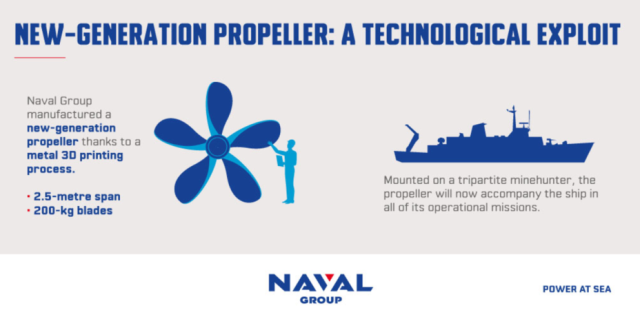

The propeller with a diameter of 2.5 m consists of five blades weighing 200 kg each. It was installed on the French Navy's Andromède-type Eridan minesweeper last year, and now it has been tested.

Installing a "printed" screw on an Andromède vehicle

Image Source: twitter.com/navalgroup

The company Naval Group points out that this is the world's first propeller, created by 3D printing technology, which is installed on the ship for everyday use, and not testing. According to the developers, the technology of metal surfacing allowed to reduce the weight of the product, improve acoustic characteristics, increase energy efficiency and product quality, as well as reduce costs and production times. In the future, Naval Group plans to expand the scope of 3D printing, creating parts that are difficult for traditional manufacturing by surfacing.

Characteristics of the" printed " screw

Image Source: twitter.com/navalgroup