The use of 3D circuits is a key factor in the continued miniaturization of electronics, however, this method has serious drawbacks. The requirement of auxiliary materials and external pressure limits the capabilities of small producers. But a research team from the National University of Singapore (NUS), led by associate Professor Benjamin Tee, can find a solution. They have developed a way to create autonomous self-healing metal structures without these needs.

Naming their technology CHARM3D, the group recently published their findings. This technology allows the use of 3D metal printing to manufacture a wide range of compact electronics, including wearable sensors, wireless communication systems and electromagnetic metamaterials.

One of the applications that the team has identified for their technology is healthcare. CHARM3D allows you to develop devices for monitoring vital signs that are completely contactless. The patient just needs to sit next to a sensor that can detect breathing and other vital signs without even touching the patient's skin.

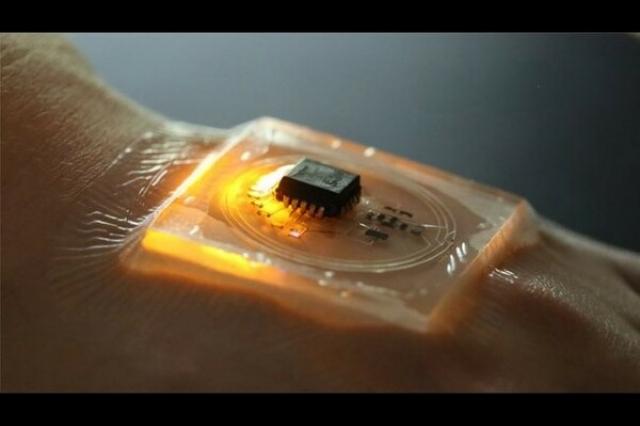

In addition, engineers have already used CHARM3D to manufacture 3D circuits for wearable battery-free temperature sensors, antennas for wireless monitoring of vital signs and metamaterials for manipulating electromagnetic waves. The team believes that this technology can provide more accurate medical imaging, such as microwave imaging of breast cancer for early detection of tumors. The researchers note that it is also promising in advanced security applications such as screening for hidden devices or contraband.

CHARM3D uses the direct ink writing (DIW) method, which is already used to make 3D circuits. However, DIW usually uses materials that are not good conductors of electricity, which requires auxiliary materials to hold the structure. CHARM3D is changing this by incorporating Field metal into the technology — a eutectic alloy of indium, bismuth and tin with a low melting point (62 ° Celsius or 143.6° F). It also hardens quickly, unlike most composite inks commonly used in DIW.

The combination of these characteristics makes Field metal an excellent material for direct ink recording of three-dimensional circuits. CHARM3D uses it to make complex freestanding three-dimensional structures such as vertical letters, cubic frames and scalable spirals.

The Ti team also emphasizes the self-healing properties of the product. Because it has a low melting point, a simple application of a heat gun can repair a broken circuit in seconds.

Ti and his team have just begun exploring the possibilities of the technology behind CHARM3D and are looking for opportunities to commercialize their work. They believe that CHARM3D has great prospects for industrial production and widespread adoption of complex 3D electronic circuits.

Photo: NUS News