The Amur-LNG space rocket complex with the Amur rocket is one of the most interesting developments of the Russian cosmonautics of recent times. The first launch vehicle, initially focused on commercial use, with a returnable first stage and powered by methane. Many innovations in one product. In many ways, this rocket could be a response to developments from SpaceX. That is why it is so interesting to find out what state the project is in and what is happening to it right now. The editorial board of Pro Cosmos spoke with Igor Pshenichnikov, Deputy Director of the Department of Advanced Programs and the Sphere project, who spoke about the most interesting moments in the development of the Amur rocket.

1. Engines for the Amur-LNG rocket

The engine for a rocket with a reusable stage is one of the most difficult and important parts of a future rocket. Firstly, a new fuel for Russian cosmonautics is liquefied natural gas. Its use will reduce the amount of soot and carbon deposits during combustion compared to kerosene engines. Secondly, such an engine must provide deep throttling (changing the power level over a large range). It's not easy either. Thirdly, it is necessary to turn on the engine several times in flight: for start, for braking in the return phase and for a soft landing.

"The assembly is currently underway. JSC "Design Bureau of Chemical Automation" (JSC KBHA) manufactures RD-0177 for the first assembly. This is a prototype engine, it will become the prototype RD-169A, which will be used in the rocket. He is preparing for the tests. They are due to start in October. Of course, there are difficulties, because engines are mostly based on additive technologies that define new approaches to technological processes, testing and design.

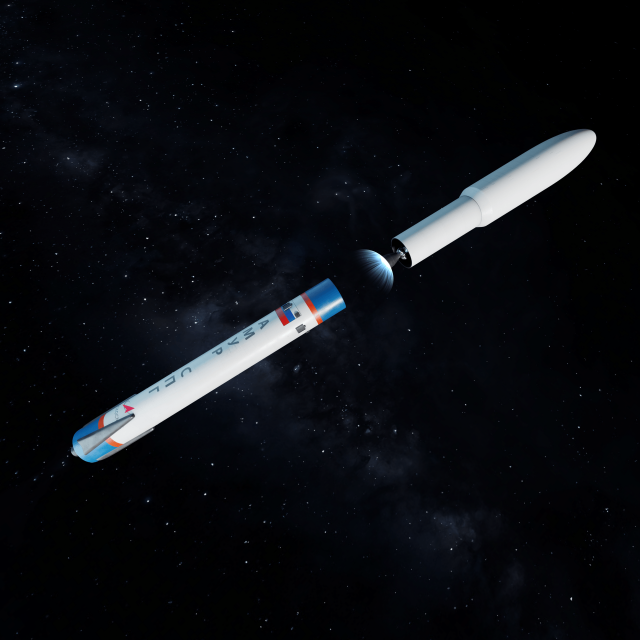

|

| The Amur-LNG space rocket complex. |

| Source: Roscosmos |

Sometimes there are some defects in the nozzle blocks, housing elements of the component supply systems. These issues can be solved, but they only take time, because these technologies are new to us. In October, as soon as the tests are completed, we will receive the first results. For us, this will be a huge start on how to form engine operation algorithms for the stage, including for the experimental one."

2. The Grasshopper

To work out the landing mode of the first stage, it is planned to use full-scale tests of the so-called "grasshopper" or hopper. This is an analogue of the first stage with an installed engine, which engineers and designers will "teach" to jump first, and then take off and land using the engine.

Such full-scale tests, although not quite typical for the Russian school of engineering, allow you to get information about the operation of engines, control systems as quickly as possible and practically test new modes on a real stand.

"Two testing sites are being considered: the Kapustin Yar landfill and, of course, Plesetsk. Depending on the volume of necessary improvements, we will choose the sites. We want to make two samples of steps based on the Soyuz-2.1v stage, because they can be quickly manufactured, and the design documentation is almost ready. They need to integrate solutions that are currently being drawn under Amur-LNG. These are landing supports, engines and control systems that will allow you to land the stage.

The problem is that while we do not know how to plant a step, no one in Russia has done this yet, no matter how our main scientific organizations beat their chests. The first tests are the take–off of the stage, hang up a little, fly without turning off the engine. If everything turns out successfully, then it means that it is already two steps ahead until we destroy them on the way, because we will try to do everything we can with them, as much as possible. We plan to use flight recorders to record the results, this is our new vision."

3. Polygons for return

SpaceX was lucky with the geographical location of the launch site for the Falcon 9 launch. The stage lands on a barge in the Atlantic Ocean, after which it is transported to the port, where it is loaded onto a huge truck carrying it along public roads to the factory for defects and preparation for the next launch.

There is no such convenient location for a cosmodrome in Russia. When launched from the East, the stage will land in fairly sparsely populated areas where the development of a road network will be required. Therefore, the issue of returning the stage for Amur LNG is a very important problem that requires a mandatory solution.

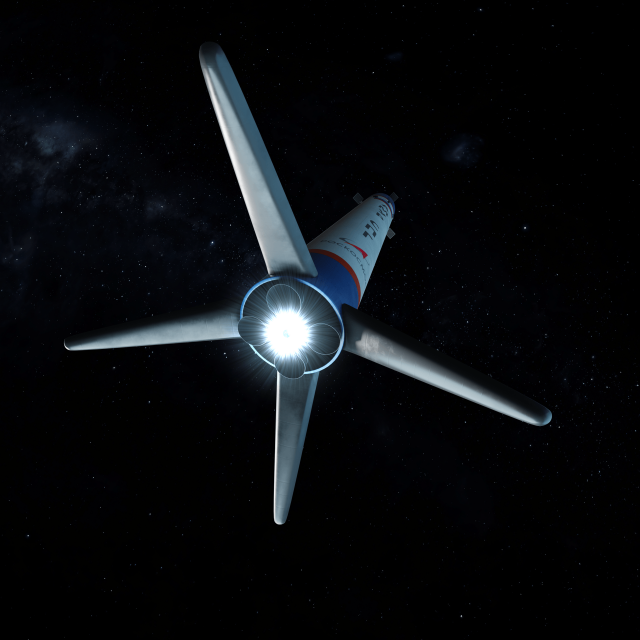

|

| The Amur-LNG space rocket complex. |

| Source: Roscosmos |

"We have two ways to return the first stage. We looked at two main inclinations when flying from the East. Neryungrinsky district, Republic of Sakha, Yakutia. The place is difficult there: in summer there is a primer, and in winter there are no roads, only winter roads. BAM is 20 kilometers away, there is both a highway and a railway.

At first, they thought to take the stage by helicopters, but it turned out that one was not enough, two helicopters were needed, and the stage was somehow disassembled. Doing this right on the spot will be difficult and expensive, especially in winter conditions.

Our main task is to minimize costs, so various options are being considered. Perhaps it is more effective to stretch the piece of iron there once. And bring everything you need to the launch directly by train before the launch. Put up beacons and cabins in two or three days. After landing, everything was transferred by cranes to the railway and everything was taken away, including the cabins."

4. Multiple engine activation in flight

Another difficulty in the development of Amur-LNG is the need to ensure multiple activation of the engines of the first and second stages in flight.

For the first stage, multiple activation is necessary to ensure the return and landing of the stage, and for the second – to ensure the separation of spacecraft without using the upper stage, which, in turn, will significantly reduce the cost of the launch service.

"The difficulty in developing an engine is its wide range of regulation (deep throttling) and multiple activation.

The multiple inclusion of engines in the design of the first stage was originally laid down and is provided with the help of piezo burners. Their design was already honed in the early noughties or late nineties at KBHA, and they work repeatedly.

There was an idea to put a fashionable laser ignition there. But I don't see the point yet, because it makes the design a little heavier and creates some risks. At least for now."

5. About the problems of industry

When creating Amur-LNG, a completely new rocket for our cosmonautics, the developers faced the inertia of production, which is easier not to create a new one, but to try to use ready-made products, even if they are not fully suitable.

"It scares me that our industry offers to engage in a simplified design method and do everything from what is already at hand. There are engines, we need to take them and screw them down. There is no need to invent or create anything new.

But this is a crisis that has been around for a long time, and it kills simply because it does not contribute to development. At the same time, I understand that changing the current situation will require a completely different look of the industry. So that it goes from product goal setting everywhere."

Mikhail Kotov