A group of scientists from Germany conducted an experiment and found out that the problem of lunar dust, and at the same time roads and landing sites on the surface of our satellite can be solved thanks to a properly selected lens, which will play the role of a concentrator of sunlight, and a local material — regolith.

If people are going to land on the moon again (after 2025, the Artemis project ), and also build a base there (by 2030, the same Artemis), they will need to solve a very important problem — lunar dust. Its very fine particles have sharp edges and have abrasive properties. In other words, the colonizers will encounter clouds of sharp fragments that can not only damage equipment and equipment, but also spacesuits, even penetrate inside them.

During the flights of Americans to the Moon, this problem has already arisen: spacesuits began to gradually lose their tightness after the first exit, dust flooded the lander and created breathing difficulties for astronauts.

One of the solutions to the problem is the construction of paved roads and landing pads, which will significantly reduce the spread of this dust. However, transporting materials from Earth to build infrastructure on the surface of the satellite will be expensive, so it is necessary to develop ways to take local resources for these purposes.

A group of scientists from different universities in Germany, led by physicist Jens Gunster, in their article published in the journal Scientific Reports, said that they were able to choose a method of high-temperature melting, with which regolith can be used to make durable structures for pavement.

Researchers have long known that regolith can be "turned" into a building material using either sunlight or a laser. To do this, the regolith is first heated until it melts, and then cooled. However, the main problem lies in the quality of the finished structure. To get the necessary building element from regolith, you need to choose the right production technology. If you use too small a beam diameter, too weak a concentration of light, focus it incorrectly, or, for example, choose the wrong power and temperature, the output may turn out to be an unsuitable part — with deformation.

Gunster and his team tried to find out whether melting regolith with a large beam of focused light could become the "right technology" for creating high-quality structures for roads and landing sites on the moon.

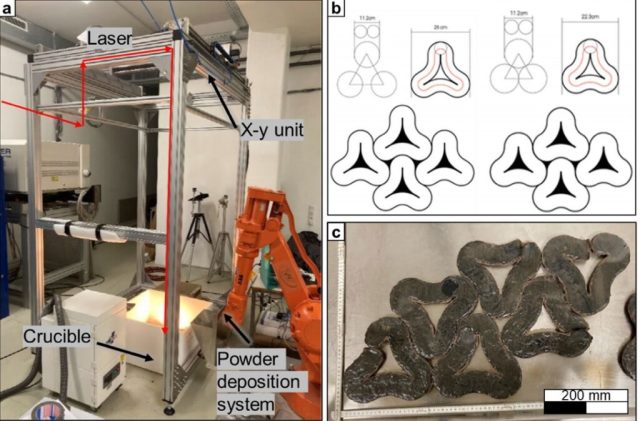

For the experiment, scientists took a carbon dioxide laser (to recreate concentrated sunlight) with a power of up to 12 kilowatts and a beam diameter of up to 100 millimeters, as well as fine-grained material EAC—1A - it acted as a simulator of lunar regolith.

|

| The picture shows a laser installation and road surface elements created using a laser. |

| Source: Jens Günster |

After that, physicists experimented with the power of the installation and the diameter of the laser beam, directing it to the EAC-1A to create a durable material. As a result, the researchers were able to select the parameters with which they were able to obtain dense triangle-like shapes with a hollow center measuring 250 by 250 millimeters. Scientists created such details using a laser output power of three kilowatts and a beam diameter of 45 millimeters.

The authors of the study noted that the new structures can work in coupling, resulting in a solid surface that can be laid on large areas of lunar soil and then used as platforms and roads.

"Such technology can be reproduced on the moon, and there is no need to send a laser, just a lens that would act as a concentrator of sunlight. If we take into account the required power and diameter of the beam, the lens will have to occupy an area of approximately 2.37 square meters," explained Gunster.

In any case, there is only one way to verify these conclusions — to send a lens of the required size to our satellite and recreate the experiment of German physicists there.