Machine vision is a technology for obtaining images, processing them and using the data obtained to solve various kinds of applied tasks without human intervention. One of the important elements of machine vision devices are photosensitive devices that convert the energy of optical radiation into an electrical signal. The holding company "Roselectronics" of Rostec State Corporation is engaged in the production of such devices. And the technology itself is already being used in full force in the work of the Corporation's enterprises. We understand what machine vision is and why it is necessary in modern technological processes.

How machines "see"

Machine vision is the eyes of modern industry. Using cameras, sensors and powerful computers, machine vision recognizes and analyzes images and allows machines to solve industrial tasks in production.

Machine vision is a key element of Industry 4.0. It helps industrial automation systems in many processes, such as improving efficiency by improving inventory, detecting faulty parts, and improving production quality.

What is the difference between machine vision and computer vision

Computer vision is a broader concept, it is a technology of image recognition and processing using a computer. It can be said that machine (or technical) vision is computer vision used in industry and in production.

For example, machine vision can be used in an industrial robot specially equipped and programmed to detect defective products on a production line. While computer vision is a system that works with algorithms that detect a visual defect. That is, machine vision includes the entire system, which both detects defects and removes defective parts from the production line.

How Machine Vision works

The work of machine vision can be divided into three stages: image capture, processing and any operation.

Photosensitive sensors, digital cameras, ultraviolet or infrared cameras are used to capture images. All these devices capture an image and convert it into digital information.

Then the digital data coming from the video equipment is analyzed using image processing algorithms. This process can also be divided into stages. Pre-processing consists of removing noise and increasing the contrast of the image. After that, in fact, the image is analyzed: its boundaries are determined, elements, signs (size, color, shape, etc.) are revealed.

After collecting and analyzing information based on machine vision, the system takes some action according to algorithms: signals an error, removes a defective part, sorts garbage, etc.

How is machine vision better than human vision

Although the human eye is a unique creation of nature, in many ways it is inferior even to the organs of vision of some animals and insects. As a tool for admiring the sunset or studying the nuances of a work of art, it is perhaps ideal. But for long, monotonous work that requires great accuracy, technical means are better suited.

A powerful computer and a camera with high detail, complemented by a variety of sensors, will give even the most experienced eye a head start. Absolute accuracy, tirelessness, maximum concentration, the ability to work with multiple objects, instant analysis – all this makes machine vision indispensable in production.

Where machine vision is used

The use of machine vision allows, on the one hand, to eliminate the human factor, the error of imperfect human vision, and on the other – to free a person from routine and redirect living employees to more important and more creative areas of activity.

The possibilities for using machine vision are quite wide.

Firstly, it is a fast and high-quality control in production. Defective parts can be quickly identified thanks to the high-speed processing capabilities of machine vision. At the same time, the possibility of error is reduced by eliminating the human factor.

Secondly, it is the work of warehouses and logistics. Thanks to machine vision systems such as barcode scanners, products can be checked quickly and precisely during storage and transportation.

Thirdly, it is a diagnosis. Visual data can be used for the operation of diagnostic maintenance systems. Machine vision data here can be supplemented with information received from heat detectors, vibration and other sensors.

Among the main areas where machine vision will be most effective, we can name quality control and diagnostics at work, safety at work, trade, healthcare, logistics, mechanical engineering.

Thus, RT-Techpriemka, the competence center of Rostec's quality management system, uses machine vision and artificial intelligence to control the quality of steel, which is used in the creation of aircraft products at the Corporation's enterprises. Steel sheets for acceptance are placed on the device platform and analyzed by video cameras. The resulting images are processed by software, and the program detects the smallest defects of the sheets based on the specified characteristics. In this way, defective products are prevented from entering production.

And the RT-Invest company has been using robots to sort garbage at its waste recycling complexes since 2021. Smart devices with the help of machine vision and artificial intelligence identify the necessary fractions in the garbage stream and use compressed air or manipulators to send them to suitable containers. Machine vision using a neural network can not only distinguish one type of garbage from another, but also, for example, distinguish the colors of bottles, their shape or degree of contamination.

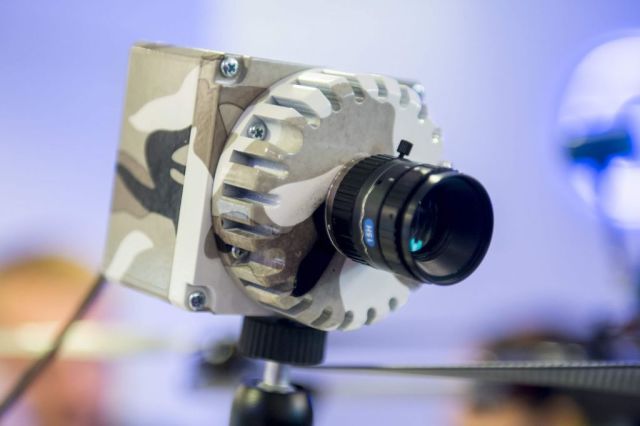

There are also enterprises in the structure of Rostec that are engaged in the development of machine vision elements. For example, the Central Research Institute "Electron" (part of the holding "Roselektronika") creates photosensitive devices used in cameras of applied television. With their help, it is possible, among other things, to register images of point radiation sources, to carry out accurate linear and angular positioning, to measure dimensions and thicknesses remotely, to monitor and review in places of limited access.

Linear photosensitive device with charge transfer. Photo: Central Research Institute "Electron" Over the past decade, the reduction in the cost of cameras and the increase in the accuracy of image recognition have led to the creation and distribution of more accurate and cheaper machine vision systems. Together with other technologies of Industry 4.0, such as the Internet of Things, big data analysis, machine learning, etc., industrial companies are achieving greater automation and production efficiency. Therefore, the machine vision market will only grow and develop in the future.