Special manipulators, giant anthropomorphic "hands" for orbital electron beam (ELS) welding were created in Izhevsk by Progress threads under the management of RT-Capital of Rostec State Corporation. The orbital welding method allows the device to "encircle" the products. Thus, the parts remain static during welding, the welding element rotates in a circle. This is necessary, among other things, to achieve high accuracy, and also allows you to work with parts and elements of any shapes and volumes. In turn, the ELS technology is used in areas where very high temperatures cannot be used, but at the same time durability and aesthetics are needed. Before Rostec, no one "welded" two methods – this is the world's first device for an orbital ELS.

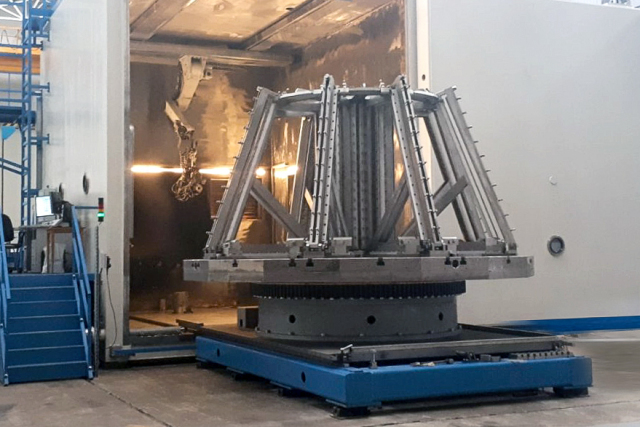

Combining technologies will make it possible to successfully connect structural elements, for example, in the rocket and space industry. And the size of the Izhevsk electronic welder will allow him to work "on a large scale", with large details.The innovative welding unit consists of two installations with "hands" that move the electron beam gun.

The design "can" rotate in the range from -400 to +400 degrees (2.5 turns). A special unit, also by the way a unique development, during the operation of the complex, folds and unfolds the cables and pipelines of the cooling system when the gun rotates.

The human factor is minimized, the entire welding process is controlled by a computer, and the operator basically only controls the work of electronic "brains" and "hands". Another unique aspect of the complex is solid volumes: each installation is 160 cubic meters.

In order to understand how the new orbital ELS welding complex works, we will fix: the essence of welding is the connection of parts at the level of interatomic bonds. Such a connection can be achieved by melting and pressure. In this case, we are more interested in melting, which, by the way, for most people far from technology and is associated with the term "welding" itself.

In the process of familiar arc welding, an electric arc acts as a heat source, but according to the ELS technology, heating is carried out by the energy of an electron beam. The method cannot be called new. The first device for electron beam welding was created at the Moscow Power Engineering Institute (MEI) back in 1958.

To create an electron beam, a complete vacuum is needed, the cost of creating it is the main drawback of the ELS technology. But there are more advantages, let's focus on them.

|

| Installation of electron beam welding AELTK-160. |

| Source: Progress Threads |

The electron beam originates in the electron gun. In a vacuum, a highly heated cathode emits electrons, which are directed to the anode, that is, the product being welded. These electrons are accelerated by an electric field generated by a special device. From this, the electrons acquire high speed and energy.

The seam when using ELS turns out to be very reliable and looks neat, while strong heat treatment can be avoided. Therefore, the technology is used in "sensitive" industries, including aircraft and rocket engineering.

So the project of creating an electronic "giant welder" on Progress was developed in the interests of Roscosmos. The manipulators have already proved themselves in practice during tests at the Krasnoyarsk Machine-Building Plant of the Space Corporation. They successfully completed the ring seams on the simulator of the missile system element. Thus, tests have shown that the Progress installation can weld large-sized parts of space technology.

Traditional arc welding is giving way to a more precise ELS method, which will increase not only the quality of products, but also the speed of production. Among the advantages of ELS can be added the fact that the technology allows welding both refractory and chemically active metals and their alloys, such as tungsten, tantalum, molybdenum, zirconium, titanium, high-alloy steel. It is known that these metals are widely used in the rocket and space industry, since the "building materials" of space technology must be refractory.

But the scope of application of ELS, and therefore potentially orbital electron beam welding, is certainly not limited to rocket and aircraft construction alone. The technology is used in power engineering, instrumentation and electro-vacuum production, is used for the production of welded gears, cutting tools. In the future, welding using electron beam technology can also help in construction when creating important load-bearing structures, such as beams and columns, tanks operating under high pressure, elements, steam generators, turbines, engine assemblies.