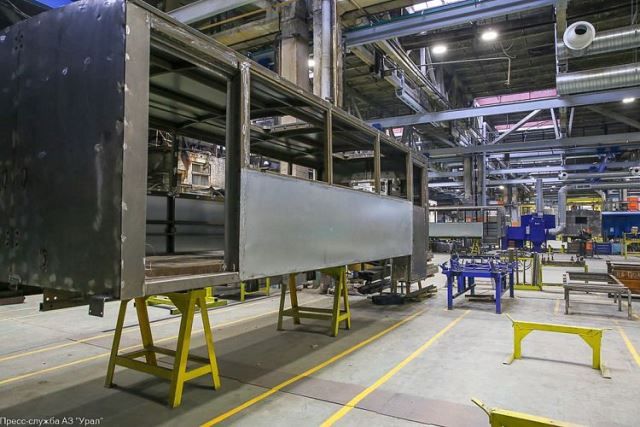

The URAL Automobile Plant has allocated more than 630 million rubles for the creation of a new centralized production, which involves a full cycle of manufacturing car superstructures. The increase in production volumes will be carried out due to the automation of processes and the introduction of robotic installations.The new workshop is located on 9,000 square meters and includes several sites, as well as a painting line of six chambers.

The idea began to be implemented in 2019, the passport of the investment project was made, the necessary calculations were made. In the summer of 2020, the first stage of the project was approved by the investment committee and was recommended for implementation. It included moving, optimal placement and starting of equipment. In accordance with the technological strategy of the enterprise, it was planned to create a full cycle of production of add-ons in one building

|

| URAL Automobile Plant. |

| Source: uralaz.ru |

The second stage of the project involves increasing production capacity and reducing costs in the production of dump trucks by automating processes, introducing new technologies and optimizing superstructure designs. These measures make it possible to increase the manufacturability of products, reduce the weight of the dump truck and, as a result, improve the technical characteristics of the finished product, which will become more competitive in the market.

|

| URAL Automobile Plant. |

| Source: uralaz.ru |

During the implementation of the project, new equipment was purchased. For example, a tipper of a dump truck platform has been purchased and put into operation, and 12 new welding machines allow you to perform work better and faster. Also, the riveting devices on the sideboard tension installation were changed, new filter ventilation units (FVU), air compressors and crane beams that ensure the work of the workshop were launched. The washing of products was fully automated. And the painting of parts is now done using a new paint supply system for the plant, which reduces its consumption.

|

| URAL Automobile Plant. |

| Source: uralaz.ru |

Full–cycle production - billet, welding, painting and assembly - was launched in August, but the project does not end there. It is planned to continue gradually acquiring new automated equipment for procurement processing, welding and painting works. This project will be fully completed in 2026.

|

| URAL Automobile Plant. |

| Source: uralaz.ru |

Today, AZ URAL is implementing a large-scale investment program, directing funds to the development of product projects, modernization of production and renewal of fixed assets, technology.

|

| URAL Automobile Plant. |

| Source: uralaz.ru |

Nikolay Krainov, Project Manager:– In addition to purchasing new equipment, we have tried to make workplaces as comfortable as possible.

Particular attention was paid to the temperature regime. Now, at the second stage of the project, opportunities are being laid for further expansion of the site of dump trucks, which will ensure the growth of production volumes in accordance with the company's product strategy. I am glad that the plant is changing so significantly and noticeably. I am sure such changes will affect every department.© URAL Automobile Plant