The United Engine Corporation has completed a program of bench tests of the first prototype PD-8 engine. The operability of the engine and its systems, the main parameters laid down in the terms of reference, the correctness of design decisions have been confirmed. This was reported in the press service of Rostec Group.

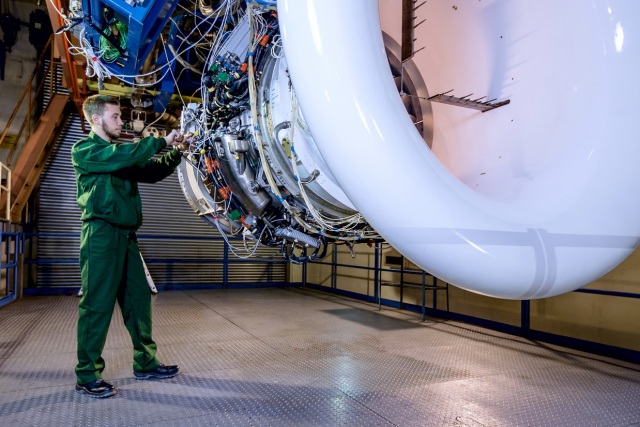

"The test program included measurements of parameters to assess the temperature condition, strength and vibration resistance of engine parts and assemblies during operation. Its air, oil and fuel systems were checked. Data on the condition of parts and assemblies of the PD-8 prototype engine were taken during tests using 500 special sensors. The data obtained with their help are subject to further analysis to assess the operability of the main nodes and systems," said Yuri Shmotin, General Designer of UEC JSC.

During the multi-stage tests, the UEC specialists debugged the automatic control systems and stabilized the engine start with the output to "small gas". The engineers carried out the required number of launches to obtain the main parameters of the engine in all its operating modes, from "low gas" to "maximum take-off" mode.

Then there will be tests of individual engine components on autonomous installations and tests as part of the Il-76LL flying laboratory, a large complex of engineering and technical calculations will also be performed. "All this is part of the complex of works to confirm the characteristics of the pilot plant to the requirements of the PD-8 engine certification basis," said Vladimir Artyakov, First Deputy General Director of Rostec.

Dual-circuit turbofan engine PD-8, which will be used on the import-substituted passenger aircraft SSJ-New and on the amphibious aircraft Be-200. SU is created using Russian materials and modern technologies, including 3D printing. A wide cooperation of UEC enterprises is involved in the work, the experience of creating the PD-14 engine is actively used.