As reported by the newspaper "Kommersant" in the material Aigul Abdullina's "Superjet" is glued from paper. The industry is arguing about the pace of creating an import-substituted SSJ," The Ministry of Trade and Industry of the Russian Federation has ordered the preparation and testing of the SSJ-New regional passenger aircraft for 15 billion rubles. Rostec announced that a 97% import-substituted modification, the development of which was estimated at 120 billion rubles, will appear by 2024. Neither the terms of certification, nor the percentage of import substitution, nor the exact list of replaced systems are discussed in the current technical task. Critics of the project do not expect a version of the aircraft to appear before 2025. But the aviation authorities and the developer of the UAC aircraft expect that the sanctions will accelerate the process.

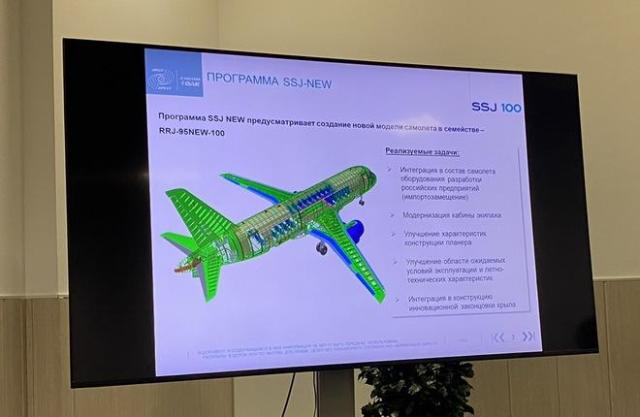

The purpose of the SSJ-NEW program was to create a modification of the aircraft with maximum use of Russian-made equipment (c) ATO.ru

The Ministry of Industry and Trade has announced a tender for 15.6 billion rubles for conducting ground and flight tests of the maximum import-substituted modification of the SSJ-New aircraft. It is necessary to complete the work - to prepare a bench base, to test the airframe units and its systems and to produce prototypes - by November 15, 2023. The result should be "a maximum reduction in the share of imported and a corresponding increase in the composition of domestic systems and components of the RRJ-95 aircraft." According to Kommersant sources, now the share of imported components in SSJ is at least 70%. In December 2020, the head of Rostec, Sergey Chemezov, said that a 97% import-substituted version of the SSJ with a Russian PD-8 engine should appear in 2024. He estimated the cost of development at 120 billion rubles.

The technical task does not formulate the final result and clear goals, the interlocutors in the aviation industry and technical specialists note. They attribute this "both to the unwillingness of performers to be responsible for the result, and to the fact that it is unattainable within 2023." "The task to produce prototypes with the notes "in the volume of 2023" means that at least something needs to be done. For example, they will make only an updated frame of wing consoles for the suspension of a new engine, but without the engine itself, without aircraft systems, etc. Therefore, they do not write that the samples will be "flight"," one of the interlocutors of Kommersant believes.

So, in the technical task we are talking about power plants based on both PD-8 and French SaM-146 engines.

The mention of SaM-146 is "another confirmation of the unavailability of PD-8," one of the experts is sure. These engines are produced by PowerJet, JV UEC-Saturn and French Safran, which on February 28 notified the airlines of the suspension of support. On March 9, the head of the Ministry of Industry and Trade Denis Manturov set the task to complete the certification of PD-8 in the "next 12-14 months". The UEC planned to certify them by 2023 and mass-produce them from 2025. It is this period that some of the experts interviewed by Kommersant consider "more realistic".

As one of the interlocutors of Kommersant emphasizes, the terms of obtaining a type certificate for RRJ-95NEW-100 are not even indicated in the technical task of the Ministry of Industry and Trade, we are talking only about the "development of certification documentation". "According to the practice of certification of both SSJ 100 and MS-21, the average time lag from the plan exceeds five years," notes another source of Kommersant. He considers it possible to complete certification with a French engine closer to 2025.

The UAC, without specifying the timing, called the conclusions about the transfer of certification "incorrect", since "there are no fundamental differences in the standard design of RRJ-95 and RRJ-95NEW-100." "SSJ-New certification is carried out as a procedure for consistent approval of a number of major and minor changes to the standard design of the RRJ-95 aircraft certified in 2011," the press service stated. A source of Kommersant in the UAC says that the availability of a primary certificate and the "need for acceleration allow us to hope" for the completion of procedures within a year.

The third set of issues is related to the lack of a detailed list of components and systems that need to be replaced - only the development of design documentation for doors (now manufactured abroad).

According to the interlocutor of Kommersant, the UAC could take as a basis the development for the Tu-204 and Tu-334, but the element base is not completely replaced. Another Kommersant source notes that KRET first announced the avionics it developed for SSJ and MS-21 back in 2015, but it is not even mentioned in the tender. "The final stage of manufacturing on-board systems for completing the first and second prototype aircraft is now underway. The equipment is delivered within the previously agreed deadlines," KRET CEO Alexander Pan told Kommersant.

Since 2020, Irkut has announced more than 20 tenders for the manufacture and supply of systems for SSJ-New, which allows us to outline an approximate range of needs. Among them are sets of passenger seats, prototypes of emergency ladders, flight information registration systems and air temperature sensors. Of the total amount of contracts for almost 4 billion rubles, the most expensive purchase was the development and delivery of prototypes of the chassis system for 1.1 billion rubles. The contest performer is hidden. "Now the disclosure of unnecessary details can leave the contractor without machines or components," explained the interlocutor of Kommersant, close to the UAC. He added that "critics in the transport lobby have done everything to make the plane unpopular during the investment phase, and now they are criticizing the aviation industry for doing so little."