The European Space Agency has summed up the results of a competition for projects to create a technology and an experimental installation for producing oxygen on an Earth satellite. The winner was assigned to develop a working prototype of a device that will extract oxygen from the lunar regolith for astronauts to breathe and use as fuel for spacecraft.

The winner of the competition was a consortium of a number of independent organizations headed by the Franco-Italian manufacturer of aerospace products Thales Alenia Space. In addition, the team includes AVS (developer and supplier of sophisticated scientific equipment, as well as electronic devices for the aerospace industry), Metalysis (a British technology company engaged in the production of powders of valuable metal alloys), Open University (the largest British public research university) and Redwire Space Europe (a company developing robotic subsystems and producing spacecraft).

The compact device will have to extract about 50-100 grams of oxygen from the lunar regolith with a target extraction rate of 70% of the total available oxygen in the sample. Moreover, it must be done very quickly — in just 10 Earth days, until the two-week lunar night has come and while the energy accumulated by solar panels is available. In addition, it is necessary to ensure accurate measurements of payload performance and gas concentration.

"The payload should be compact, low-power and compatible with a number of potential lunar landers, including EL3, the European Space Agency's (ESA) own lander. The ability to extract oxygen from the lunar soil together with usable metals will be a decisive factor for the exploration and exploration of the Moon, while eliminating dependence on long and expensive supply lines with the Earth," explained David Binns, a systems engineer from the ESA Parallel Design Center.

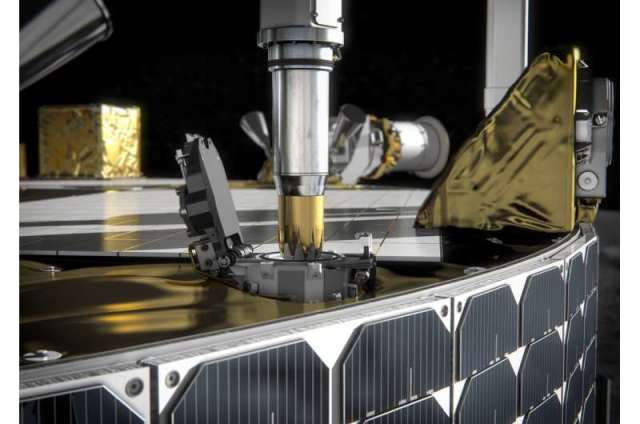

The lunar lander collects a sample of the lunar regolith in the artist's view.

Image Source: ESA

Giorgio Magistrati (Giorgio Magistrati, head of the technology research group working within the ESA ExPeRT initiative, added: "It is time to start working on the implementation of the ISRU technology demonstrator for the use of in-situ resources [on site]. This is just the first step in our larger ISRU implementation strategy. Once the technology is tested using this primary payload, our plan will culminate in a full-scale ISRU installation on the lunar surface at the beginning of the next decade."

The concept underlying the technology of extracting oxygen from the lunar regolith has already been proven and tested experimentally. Analysis of lunar soil samples delivered to Earth confirms that regolith consists of 40-45% oxygen (by weight). The only difficulty lies in the fact that this oxygen is chemically bound in the form of oxides in minerals or glasses, so it is not available for immediate use.

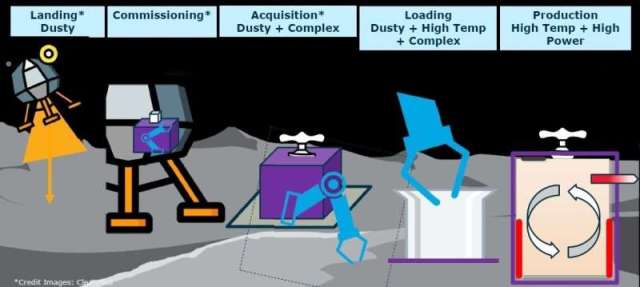

Schematic representation of a future mission to prove the work of a demonstrator of oxygen extraction technology from lunar regolith. The demonstrator will have to land, undergo testing and adjustment, take a sample of lunar soil material, load it into the demonstrator, which will then receive oxygen from it.

Image Source: ESA

Nevertheless, the prototype of the oxygen extraction plant was created in the Laboratory of Materials and Electrical Components of the European Center for Space Research and Technology (ESTEC). This facility uses an electrolysis-based process to extract key resources for long—term manned space missions - metals and oxygen - from the simulated lunar regolith.