Researchers from Ajou University, South Korea, have created a mechanical automated "hand" with such high precision of movements that it can take, lift and hold chicken eggs without damage, cut paper with scissors, and use tweezers to take and place microchips and other tiny electronic components on the surface of the printed circuit board. In addition to the high accuracy of movements, the new mechanical arm has a very impressive strength, it is able to crush an aluminum can from under a drink or lift a dumbbell weighing up to 18 kilograms.

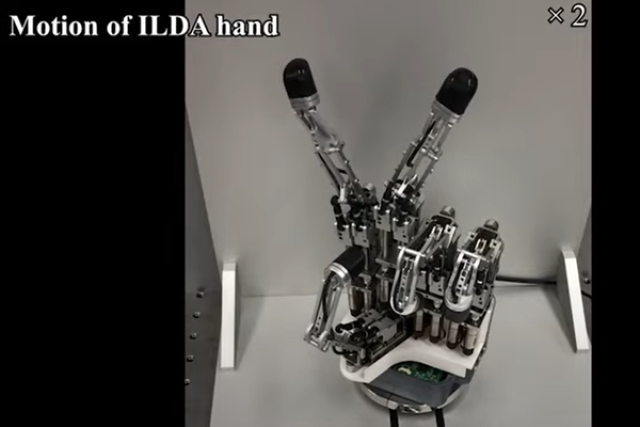

The design of the mechanical arm is made mainly of lightweight aluminum with some steel elements, due to which it weighs 1.2 kilograms with a length of 22 centimeters. The arm consists of 20 movable joints held together by metal parts and springs that work as artificial tendons. And each finger is driven by three independent small electric motors located inside the wrist.

This design allows the mechanical arm to perform all the movements that a human hand is capable of performing. And the highest accuracy of movements is provided by appropriate sensors and a high-quality electronic control system.

During the tests, the arm design demonstrated high reliability. With repeated repetition of the same action for a long time, the researchers did not register any decrease in the accuracy of movements, nor a decrease in the efforts developed at the same time.

The current version of the mechanical arm can already be installed on robots of various types using control systems based on artificial intelligence. And now Korean researchers are working on a lightweight version of such a device, which will become the basis of new types of high-tech prostheses. Only for this you will need to cover the mechanical hand with artificial leather, which will provide a soft touch and at the same time, be a sensor that provides tactile feedback.