AZAK company from Denver (USA, Colorado) positions itself as a center of innovation in the field of unmanned ground mobility. The company's engineers have designed a ground-based robotic platform with a unique configuration. The device is based on an autonomous wheel system, rather than a traditional frame. Instead of axles, transmissions, and a fixed body, the company has designed each wheel as an autonomous power unit that houses the engine, battery, and main drive components.

The architecture allows you to increase the torque by adding wheels, reduces the center of gravity and makes it possible to overcome obstacles rather than go around them. Such a ground robot without a chassis behaves differently than conventional SUVs. It offers a higher payload-to-weight ratio, improved stability on uneven terrain, and the ability to assemble platforms in multiple configurations without redesigning the vehicle structure.

The concept has become a central theme in AZAK's work with the U.S. Army, sparking interest from units looking for mobile resupply solutions, counter-UAVs, perform evacuation tasks if necessary, and drone launch systems.

The army command tested the AZAK development in October 2025, during the xTechOverwatch competition at the National Training Center training ground. The purpose of testing was to understand whether this platform allows you to change the approach to planning and completing tasks by squads. The soldiers used the system to perform various field tasks, including transporting goods, moving over rough terrain, and launching small drones.

According to the reviews of the personnel, the robotic platform from AZAK "allows you to use more weapons in combat, relieves the burden associated with carrying heavy loads, and can also be used to launch small drones without risk to the soldier." According to the developer, during the events, the system could withstand a load of more than 227 kg on rough terrain and changed the tactics of the squad at each stage of the tests.

The AZAK robotic platform overcomes a rocky obstacle, carrying a load weighing about 250 kg.

The AZAK management identifies three main factors that influenced the design of the product:

- Low center of gravity: all drive components are located inside the wheel and below its center, which increases stability and maneuverability.

- Higher payload-to-weight ratio: The absence of axles and landing gear reduces the weight of the system.

- Flexible modularity: the wheel can be mounted on any platform designed for a specific task, without a special housing.

"We do not produce individual vehicles, we provide the basic engine for ground–based autonomous systems in an infinite number of configurations," AZAK said.

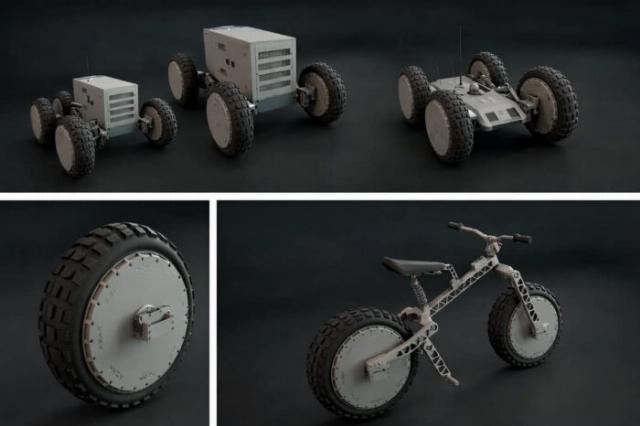

A variety of AZAK configurations

Regarding navigation control and obstacle avoidance, the developer's representative explained that the platform is designed to simplify autonomous driving, rather than using sophisticated obstacle avoidance software. In other words, it is "independent of control" and can be integrated into any stack of autonomous driving, and the mechanics of the system allow it to interact directly with the terrain.

The AZAK robotic platform with another ground-based RTK during testing of xTechOverwatch 2025.

According to the developers, for the platform, "obstacle avoidance is often not required. Stability, power, and ground clearance allow it to overcome objects that other vehicles must detect, avoid, or simply cannot overcome."

Wheel S26

The latest S26 wheel in a four-wheeled configuration can withstand loads of up to 700 kg, which allows for long-range operations and the integration of heavy payloads such as reconnaissance systems or kinetic interceptors of UAVs.

The development concept is based on a multi-module configuration. Each wheel has an independent transmission, which allows you to increase the torque linearly when adding wheels or modules. The standard 4-wheel configuration provides constant torque of 588 lb-ft (about 796 newton meters). When switching to a 6-wheel configuration, the system provides a linear increase in torque to 882 lb-ft (about 1,195 newton meters). The company is reportedly developing a wider range of new mission profiles and advanced configurations, without being tied to specific payloads or variants.

The AZAK robotic platform at the SOF Week exhibition

It is reported that in 2025, AZAK faced high demand for its products. Active cooperation is maintained with special operations forces, brigade combat teams, and army modernization units that have focused on medical and logistical needs. Currently, the military is exploring the platform as a mobile base for new systems, in particular: platforms for launching drones, kinetic anti-UAVS; communication relay modules, mobile power plants, as well as heavy equipment maintenance facilities.

Source: Defense Blog