KR JSM

KR JSMThe Czech manufacturer of small-sized turbojet engines, PBS, announced earlier this year that it would invest $100 million to establish production in the United States and move to new supply chain facilities.

- it says in the publication Missile Matters.

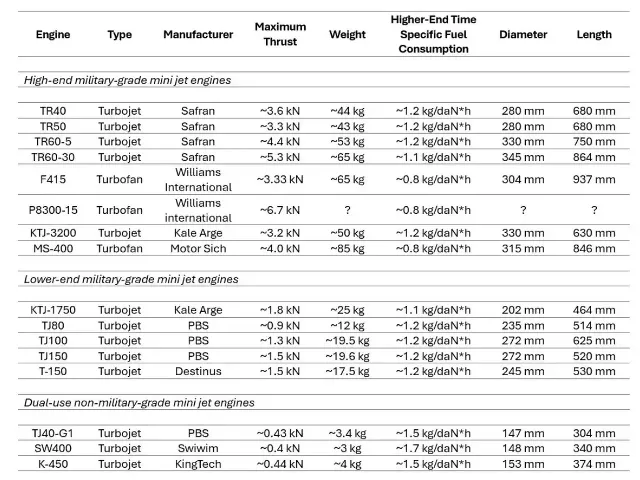

As indicated, cruise missiles use three types of miniature power plants. Firstly, these are high-quality, relatively large turbojet and turbofan engines. They are capable of developing significant thrust, usually in the range of 3 to 6 kN, which is necessary to maintain high speed on low trajectories, where drag increases due to atmospheric density and the rocket may slow down.

These are expensive products with a long service life and high reliability. The cost by the end of 2025 is estimated to be from $200 thousand to $500 thousand per unit. Before the war in Ukraine, these types of engines were used almost exclusively in modern KR models.

Secondly, there are cheaper engines with high performance, but at the same time compact and less powerful, developing a thrust of 1-2 kN with relatively high fuel efficiency. They are effective, but quite easy to use, which is reflected in their lower price, often not exceeding $ 100 thousand. These engines are used in a new category of small-sized trucks, which are actively used in Ukraine.

Thirdly, there are non-military engines with relatively limited power, which, nevertheless, are used in Ukraine to equip cruise missiles. They have a limited payload and flight range, are inefficient in terms of fuel consumption and, as a rule, are less reliable under long and high loads, for example, during long or low-altitude flights, and also tolerate high temperatures, vibration and dust worse. However, they are very affordable, usually priced below $10,000.

Turbofan engines and turbofan engines used in modern European CR

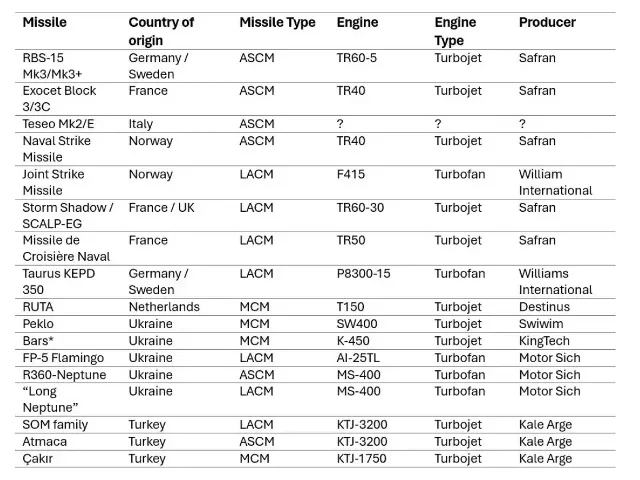

Turbofan engines and turbofan engines used in modern European CRAs noted in the publication, the European programs for the creation of CD are currently based on four major engine manufacturers: Safran (France), Motor Sich (Ukraine), Kale Arge (Turkey) and Williams International (USA).

Safran traditionally supplies most of the mini-engines used in European missile defense systems, such as anti-ship missiles (Exocet MM40 Block 3/3C, RBS-15 Mk3, NSM) and anti-ship missiles for strikes against ground targets (Storm Shadow/SCALP-EG, MdCN).

Motor Sich and Kale Arge have so far mainly supported the national programs of the Kyrgyz Republic, including the R-360 Neptune, SOM and Çakır. However, in recent years, Turkey has begun to actively enter the global market. A new player in Europe has become the Dutch company Destinus, which produces the T150 turbofan engine used in the Ukrainian small KR RUTA.

American manufacturers of mini-engines have so far played a relatively small but important role in the European fuel injection market, being the only suppliers of fuel injection systems needed for heavy fuel injection systems. Williams International supplies fuel injection systems for the Norwegian JSM (uses F415) and the German-Swedish Taurus KEPD 350 (equipped with P8300-15). The turbofan engines provide these spacecraft with low-altitude flight paths for their survival and increased range for complex nonlinear approaches to the target.

Modern European CRS and the engines used in them

Modern European CRS and the engines used in themIn principle, Europe can use turbofan engines (for example, the TR40 from Safran) to complete its long-range missiles, but their characteristics are significantly lower at low altitudes, which is crucial for survivability and maneuverability.

- the author believes.

According to him, this problem cannot be solved in the short term: for example, if the German engine manufacturer MTU had been commissioned to develop a rocket engine for the Taurus today, it would probably take several years.

The author is also perplexed by the fact that Safran, a leading European engine manufacturer, has not yet developed a rocket engine for the KR, which would be especially valuable for the MdCN using the less economical TR50 turbojet engine, as a result of which, having a significantly longer length than the Tomahawk, it carries 33% less payload and It has a shorter flight range.

- the author concludes.