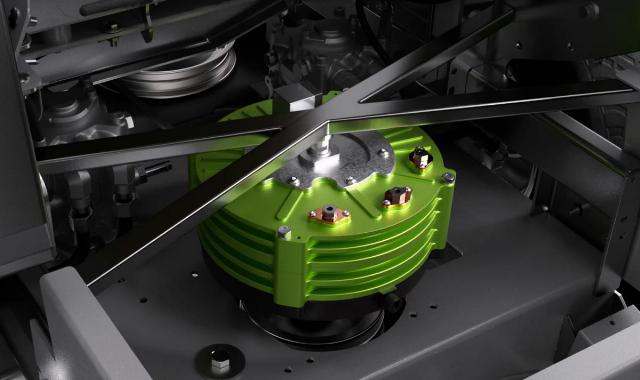

The Conifer engine

Difficulties with obtaining rare earth materials by Western countries, including neodymium, dysprosium and terbium for the manufacture of powerful magnets, gave a chance for the development of non-standard propulsion technologies. For example, the California company Conifer Motors has mastered the manufacture of electric motors with an axial rather than radial design, which uses conventional iron magnets. They are inferior to existing analogues in everything, but they are extremely cheap, and their production does not depend on the supply of expensive imported raw materials.

The axial design of electric motors has been known since the 19th century and was already considered impractical at that time. Such engines are difficult to manufacture, they are capricious, unreliable, low-power, and have many cooling problems. However, modern technologies and materials can eliminate most of these problems, and the production of such electric motors becomes cost-effective. The question is about their application.

The Conifer engine

The key disadvantages of axial motors cannot be eliminated, and therefore they cannot be used for critical tasks, such as installing them on electric vehicles. But they are perfect for places where minimum power is required (up to 25 hp), such as ventilation systems, air conditioner engines and other household appliances, toys, electric scooters, etc. And since such things require a lot, making them cheaper becomes the cornerstone of the whole idea. Unlike rare earth metals, iron can be found almost everywhere, and it is also easier to process. But the main thing that the United States is currently focusing on is the opportunity to get rid of strategic dependence on other countries for the supply of important resources. For this, it is proposed to abandon powerful and convenient magnets where it is not critical, albeit at the cost of some reduction in benefits and quality of life.

Alexander Martynenko