Over the past decades, scientists have tried many different ways to produce building materials on the Moon, but mostly they required various additives for strength, turned out to be energy-intensive or involved the creation of monolithic large structures. Now, a team of space engineers has demonstrated a technology that makes it possible to dispense with only lunar soil and relatively economically manufacture small parts of the "constructor" from it.

Construction on the Moon is not only a matter of an uncertain and distant future: they are trying to solve it already within the framework of current plans to create permanent scientific bases on the satellite of our planet. Of course, they will be deployed from ready-made modules, but additional radiation protection will be needed, and covering the station's buildings with soil would provide just such protection.

Various ways of solving this problem are offered. For example, in 2020, European engineers showed concrete that could be made on the moon. For him, in addition to the lunar soil itself, water is needed, and it is in a liquid state.

Large deposits of water ice are stored in the lunar polar regions. This means that for the production of concrete, it must be extracted together with regolith and melted under sufficient pressure, otherwise, in the atmosphere-free lunar environment, ice will sublimate when heated, that is, it will immediately turn into a gaseous state. In addition, this technology involves the use of astronauts' urine to make the material plastic.

Researchers around the world are trying to make the process of constructing structures from lunar matter as simple and economical as possible. Recently, engineers from universities in the USA and Finland described their option for achieving this goal in an article available on the preprint server. arXiv.org .

Specialists have created an experimental installation that makes small "bricks" of powdered regolith by laser sintering: it is necessary to place a thin layer of this substance on the working platform, under the action of a laser beam, the grains of sand in it fasten together and form a single whole, then a new layer is poured on top, and the process repeats.

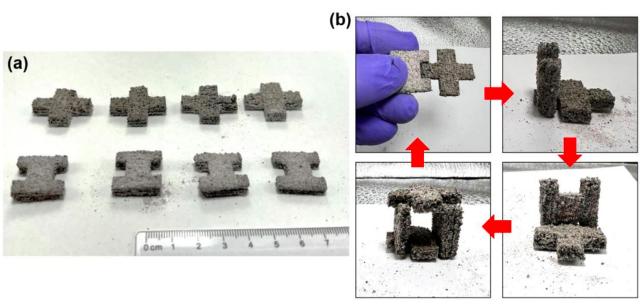

As part of the demonstration test, several centimeter—sized cubes and parts of more complex shapes were made in this way - in the form of a "cross" and the letter "H". They can be connected to each other, as when assembling a construction kit, that is, without the need for bonding with cement or something similar.

Building blocks made from an analog of lunar regolith by laser sintering

Image source: Cole McCallum et al, 2025

The engineers used not real lunar soil as a raw material, but its most similar analogue. The built installation requires a total of no more than about 120 watts of electricity. On the moon, it could be powered by a small radioisotope generator. Solar panels can also be used, but two-week moonlit nights must be taken into account. A real "machine" should be much more productive and require much more energy, but the developers consider this achievable.

On the other hand, they also recognize problems: the blocks turn out to be too rough, which means that the connection is not tight enough. In addition, the question arises about the strength of the products: the pressure perpendicular to the layers — that is, "from above" — the products withstand noticeably worse than the pressure "from the side".

Adele Romanenkova