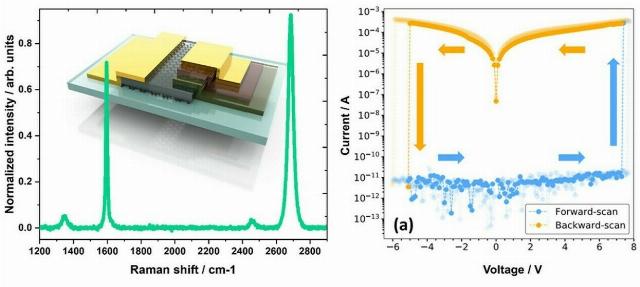

The study confirms the concept and suitability of graphene for improving the characteristics of memristors compared to other materials

Researchers from Queen Mary University of London and the company Paragraf Limited have made significant progress in the development of graphene-based memristors.

The achievement, published in the ACS Advanced Electronic Materials journal, represents an important step in the scalable production of graphene-based memristors, which are essential for non-volatile memory and artificial neural networks.

Memristors, devices capable of performing analog calculations, storing data without power supply and simulating the synaptic functions of the human brain, are recognized as potential revolutionary devices in the field of computing. The integration of graphene, the material with the highest electron mobility among all known substances, can significantly improve these devices. However, until recently, it was extremely difficult to scale and implement graphene into electronics.

One of the key challenges in the development of memristors is the degradation of the device, which graphene can help prevent. By blocking chemical pathways that destroy traditional electrodes, graphene can significantly extend the life and reliability of these devices. Its transparency, which transmits 98% of light, also opens the door to advanced computing applications, especially in the fields of artificial intelligence and optoelectronics.

Source: ACS Applied Electronic Materials (2024). DOI: 10.1021/acsaelm.4c01208

The research is an important step towards the scalability of graphene electronics. Historically, the production of high-quality graphene compatible with semiconductor processes has been a significant obstacle. However, the Paragraf patented metal-organic chemical vapor deposition (MOCVD) process now allows monolayer graphene to be grown directly on target substrates.

This scalable approach is already being used in commercial devices such as graphene-based Hall sensors and field effect transistors (GFETS).

The team used a multi-step photolithography process to model and integrate graphene electrodes into memristors, producing reproducible results that open the way to large-scale production.