The development and introduction of three-dimensional printing is called the industrial revolution. Printed parts are lighter and stronger, raw materials are used without waste, there is no need to modify the finished products with a"file". Additive technologies are used for the manufacture of elements of turbojet and helicopter engines, combustion chambers. The state, prospects and development of additive technologies were discussed at an open table organized by the D. I. Mendeleev Russian State Technical University.

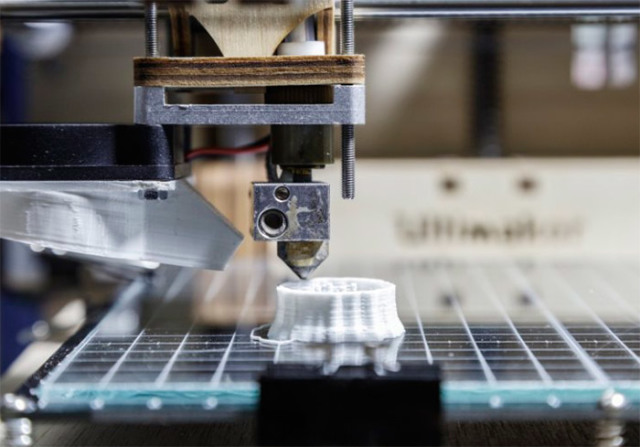

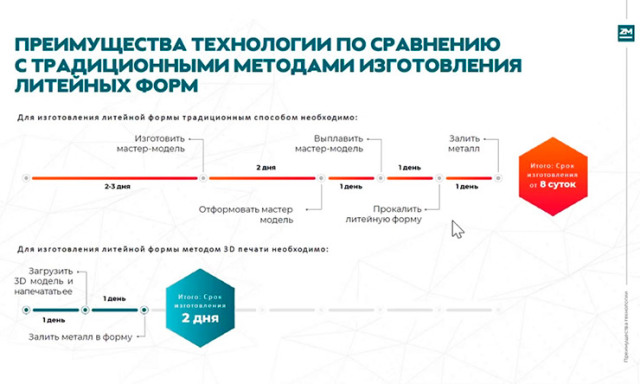

Additive technologies are a method of layer-by-layer construction of objects. Such methods began to develop in the early 1980s, and now scientists and industrialists note their advantages over traditional methods of manufacturing polymer and metal products. Working with printing, technologists can calculate the amount of raw materials that will be required for production - there is no loss, which in classical processing can reach 85 percent. It has become possible to produce new elements for the space and aviation industries - printing technology makes it possible to realize internal cavities that were impossible.

And the article about 3d bioprinting in space is among the 20 most cited in the world: on the ISS, it was possible to print cartilage and thyroid gland, and this is called the beginning of the technology.

Both metallic and non-metallic additive technologies are used in the space industry, said Yuri Urlichich, First Deputy General Director of Roscosmos . This method is used to make elements from the body parts and brackets to the nozzles of liquid-jet engines. And the size of the products can exceed 10 meters.

As one example, we used elements of the microwave path: using additive technologies, we managed to combine 13 parts into one, make the part 2.5 times lighter and make it ten times faster.

Along with the air industries, the benefits of three-dimensional printing were also discussed by oil workers - in the company "Sibur", which is engaged in the processing of resources, they came to the need to introduce additive technologies. In particular, 3d printing allows you to prepare parts for repair on the spot: there is no need to keep separate repair facilities, the recovery time of equipment is reduced, and problems with the lack of parts that have been removed from production disappear.

The rector of the St. Petersburg State Marine Technical University spoke about some of the domestic developmentsGleb Turichin. Many machines for three-dimensional printing, which are produced in Russia, partly depend on supplies from abroad. They are competitive, but if some of the elements stop delivering, development will stop. For example, in the technology of layer-by-layer growth, scanners are used - devices that deflect the laser beam along the X and Y axes using two rotary mirrors. Some of their models stopped being brought to Russia and the development of the domestic machine for layer-by-layer build-up began.

The conference noted the factors that hinder the development of additive technologies in Russia. Among them, they noted a lack of understanding of the economic benefits of three-dimensional printing, the lack of regulatory documents that would describe the production processes associated with additive technologies and the lack of a training system, as well as a shortage of qualified specialists. They plan to cope with the last factor by the mid-2020s: students who will work with additive technologies should have received diplomas by this time, now they are just starting to study.

Konstantin Krylov