Memory devices based on switching resistance have significant advantages over the memory elements used today. Employees of the MIPT atomic layer deposition laboratory together with colleagues from Korea studied the effect of surface defects in one of the electrodes on the properties of a resistive memory cell. It turned out that as the thickness of the electrode increases, the surface roughness increases sharply, and the parameters of the memory cell noticeably improve.

The results are published in the journal ACS Applied Materials & Interfaces. Some substances can switch from the dielectric state to the conductive state and back when an electric voltage is applied to them. The threshold voltage, the ratio of resistances in different States, and other parameters depend on the substance located between the electrodes.

This principle is the basis for the operation of random-access resistive memory — one of the most promising types of non-volatile memory. Resistive memory devices based on transition metal oxides are characterized by low power consumption, durability, ease of expansion and speed of operation, so many companies are encouraging the development of this type of memory.

A memory cell of this type is a layered structure between two electrodes to which a switching voltage is applied. Its properties depend not only on the substance between the electrodes, but also on the composition and shape of the electrodes themselves. Today, one electrode is made mainly from titanium nitride, and the second — from platinum. However, platinum is incompatible with the semiconductor structures used in computer circuits.

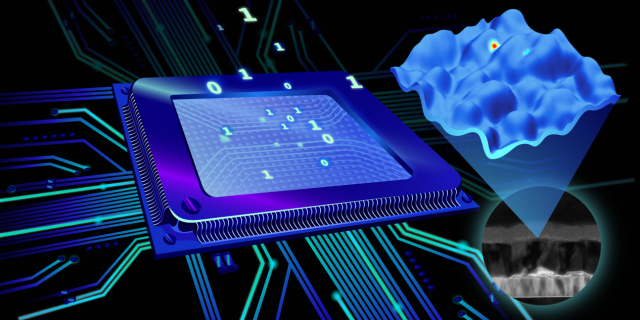

Ruthenium, unlike platinum, [...] does not have this problem, in addition, ruthenium electrodes can also be obtained by atomic layer deposition, which makes it possible to produce three-dimensional vertical memory structures. Alexandra Koroleva, PhD student at the Phys tech school of electronics, Photonics and molecular physics, one of the authors of the article, comments: "We grew ruthenium electrodes with different numbers of atomic layer deposition cycles to study the effect of electrode thickness on cell parameters. Next, the surface of the electrode was examined using an atomic force microscope."

It turned out that as the number of deposited layers increases, the grain size on the electrode surface changes from 5 to 70 nanometers. The researchers then used ruthenium films as the lower electrode in tantalum oxide-based resistive memory structures. It was shown that an increase in the thickness of ruthenium leads to a decrease in the resistance of the cell in both States, as well as to an increase in the ratio of resistance values in the dielectric and conducting States.

An increase in the surface roughness of the ruthenium electrode also led to a decrease in the forming voltage and switching voltage. In addition, the device's resource has significantly increased, reaching 50 million rewrite cycles for the device with the roughest electrode. This means that increasing the roughness of the electrode improves the important characteristics of the device for practical applications-durability and energy efficiency.

To explain the effect, scientists proposed a simplified model that demonstrates the localization of the electric field on the slopes of the largest grains on the ruthenium surface. This assumption was confirmed by conducting atomic force microscopy.

"Our results will help us understand how a new type of memory cell can be significantly improved. An increase in the thickness of the ruthenium film leads to an increase in the surface roughness of the electrode. At the same time, regions of local concentration of the electric field are formed on the grain slopes, which, in turn, significantly improves the key characteristics of the device.

The results give us hope that memory devices will have better performance and reliability in the future, " adds Andrey Markeev, head of the MIPT atomic layer deposition group. This work was supported by the Russian science Foundation and the Ministry of science and higher education of the Russian Federation.

Phys tech

201 articles

Moscow Institute of physics and technology (national research University), also known as fiztech, is a leading Russian University for training specialists in theoretical, experimental and applied physics, mathematics, computer science, chemistry, biology and related disciplines. Located in the city of Dolgoprudny, Moscow region, separate buildings and faculties are located in Zhukovsky and Moscow.

Show more